Safety

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

26 Mentor MP User Guide

www.controltechniques.com Issue: 3

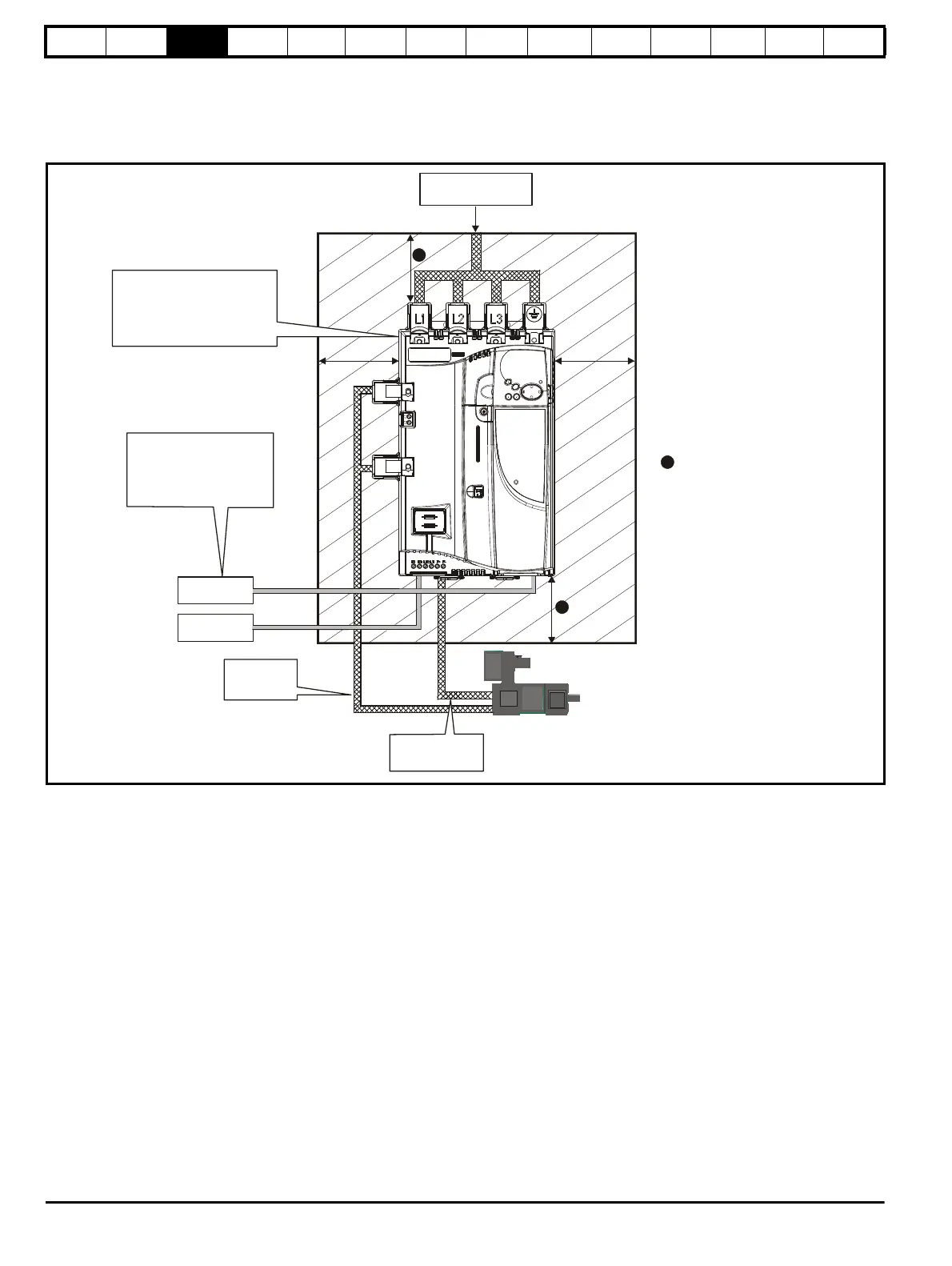

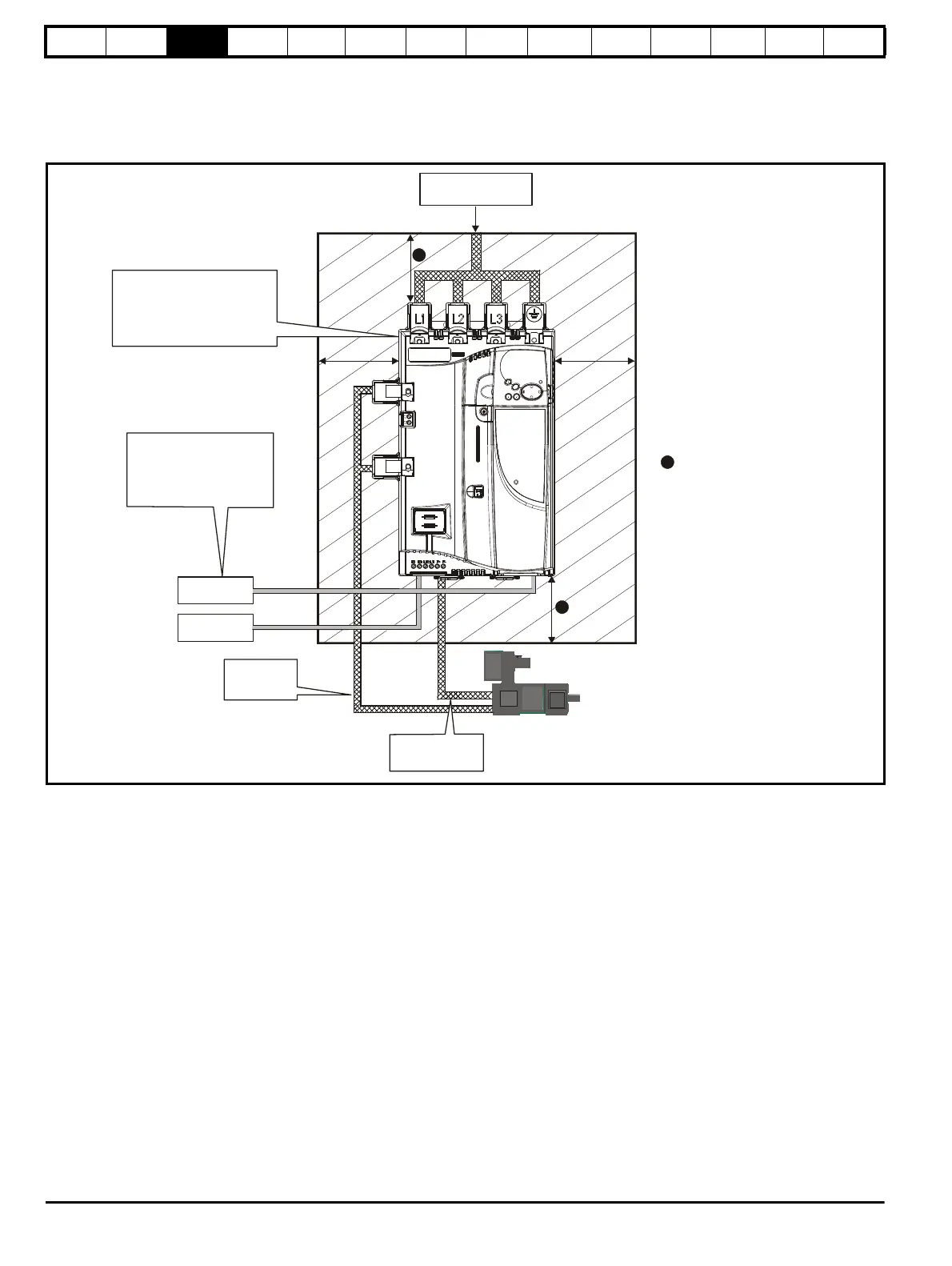

3.6 Enclosure

3.6.1 Enclosure layout

Please observe the clearances in the diagram below taking into account any appropriate notes for other devices / auxiliary equipment when planning

the installation.

Figure 3-17 Enclosure layout

3.6.2 Enclosure sizing

Refer to section 12.1.2 Typical short-term overload limits on page 145

for drive losses.

Add the dissipation figures for each drive that is to be installed in the

enclosure.

Add the power dissipation figures for each EMC filter that is to be

installed in the enclosure.

Calculate the total heat dissipation (in Watts) of any other equipment to

be installed in the enclosure.

Add the figures of all of the above to get a total heat dissipation figure (in

Watts) for the equipment in the enclosure.

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding

air by natural convection. The larger the surface area of the enclosure

walls, the better is the dissipation capability. Only the surfaces of the

enclosure that are not in contact with a wall or floor can dissipate heat.

Calculate the minimum required unobstructed surface area A

e

for the

enclosure from:

Where:

A

e

Unobstructed surface area in m

2

(1 m

2

= 10.9 ft

2

)

T

ext

Maximum expected temperature in

o

C outside the

enclosure

T

int

Maximum permissible temperature in

o

C inside the

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

k Heat transmission coefficient of the enclosure material

in W/m

2

/

o

C

Example

To calculate the size of an enclosure for the following:

• Two MP25A4 models operating under full load conditions

• Maximum ambient temperature inside the enclosure: 40°C

• Maximum ambient temperature outside the enclosure: 30°C

Dissipation of each drive: 125W

Dissipation from other heat generating equipment in the enclosure. 11W

(max).

Total dissipation: 2 x (125 + 11) = 272W

Enclosure

AC supply contactor,

External

controller

Ensure minimum clearances

are maintained for the drive.

Forced or convection air-flow

must not be restricted by any

object or cabling

Auxillary

supply

Signal cables

Plan for all signal cables

to be routed at least

300mm (12in) from the

drive and any power cable

Armature

connection

cable

Field

1) Power cabling must be at

least 100mm (4in) from the

drive in all directions

2) Ensure direct metal contact

at drive and filter mounting

points (any paint must be

removed)

100mm for Size 1 drives

200mm for Size 2A/2B drives

leave a clearance of 100mm

A

e

P

kT

int

T

ext

–()

----------------------------------------

=

Loading...

Loading...