ZB Series

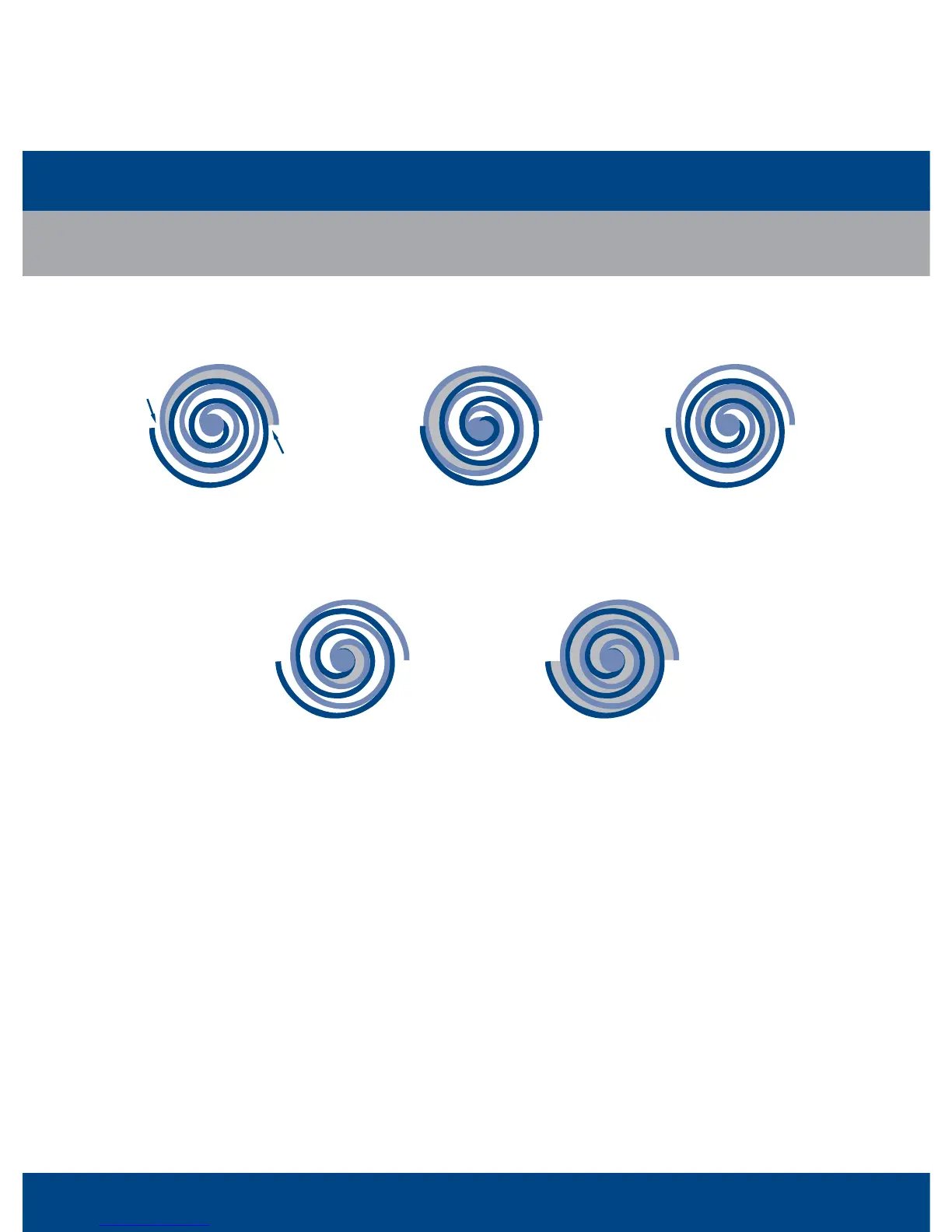

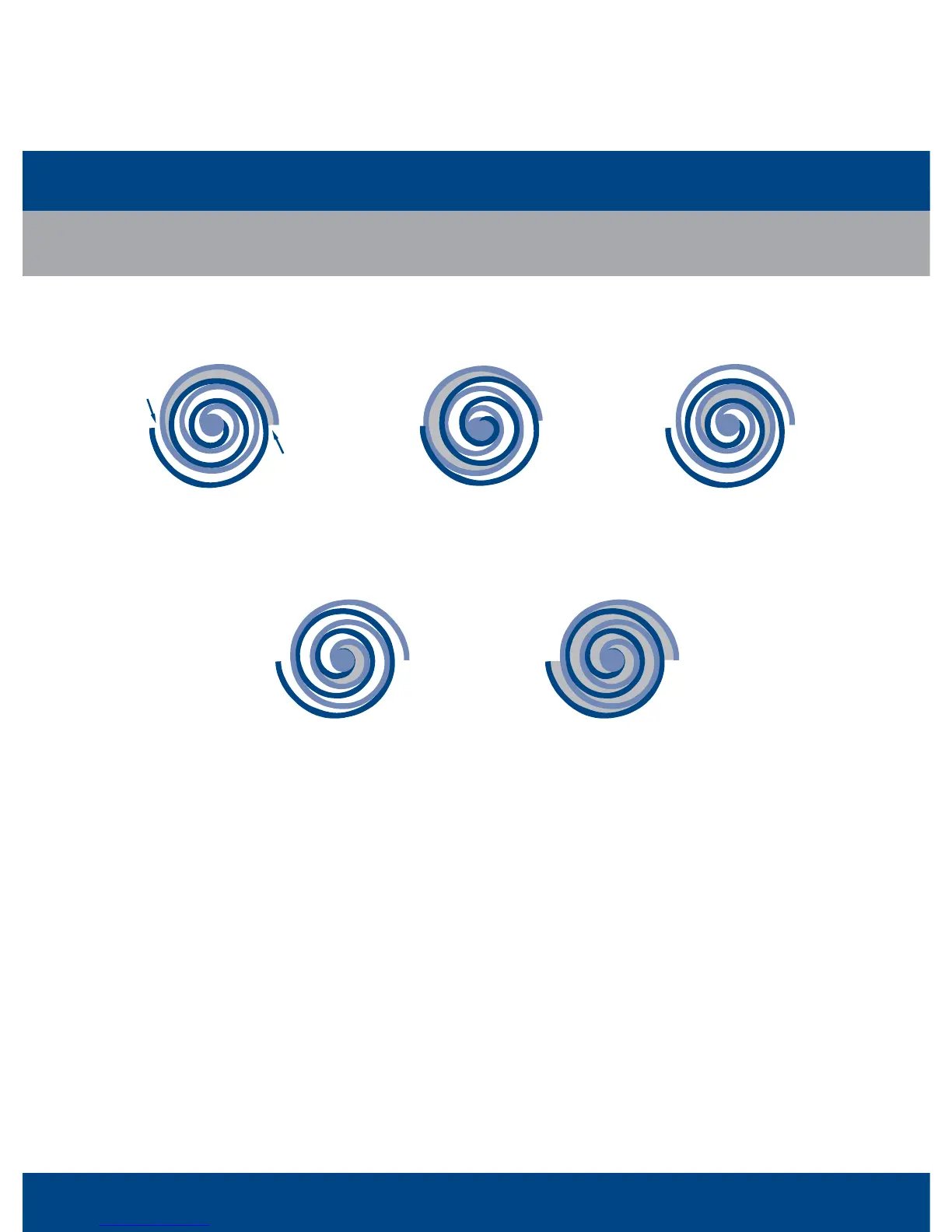

1. Scroll Compression process

Application Guide

Compression in the scroll is created by

the interaction of an orbiting spiral and

a stationary spiral. Gas enters the outer

openings as one of the spirals orbits.

The open passages are sealed off

as gas is drawn into the spiral.

As the spiral continues to orbit,

the gas is compressed into two

increasingly smaller pockets.

By the time the gas arrives at the

center port, discharge pressure has

been reached.

Actually, during operation, all six

gas passages are in various stages

of compression at all times,

resulting in nearly continuous

suction and discharge.

The scroll is a simple compression concept first patented in 1905. A scroll is an involute spiral which, when matched with a mating scroll form as shown

above, generates a series of crescent-shaped gas pockets between the two members. During compression, one scroll remains stationary (fixed scroll)

while the other form (orbiting scroll) is allowed to orbit (but not rotate) around the first form. As this motion occurs, the pockets between the two

forms are slowly pushed to the center of the two scrolls while simultaneously being reduced in volume. When the pocket reaches the center of the

scroll form, the gas, which is now at a hige pressure, is discharged out of a port located at the center. During compression, several pockets are being

compressed simultaneouly, resulting in a very smooth process. Both the suction process (outer portion of the scroll members) and the discharge

process (inner portion) are continuous.

6

Loading...

Loading...