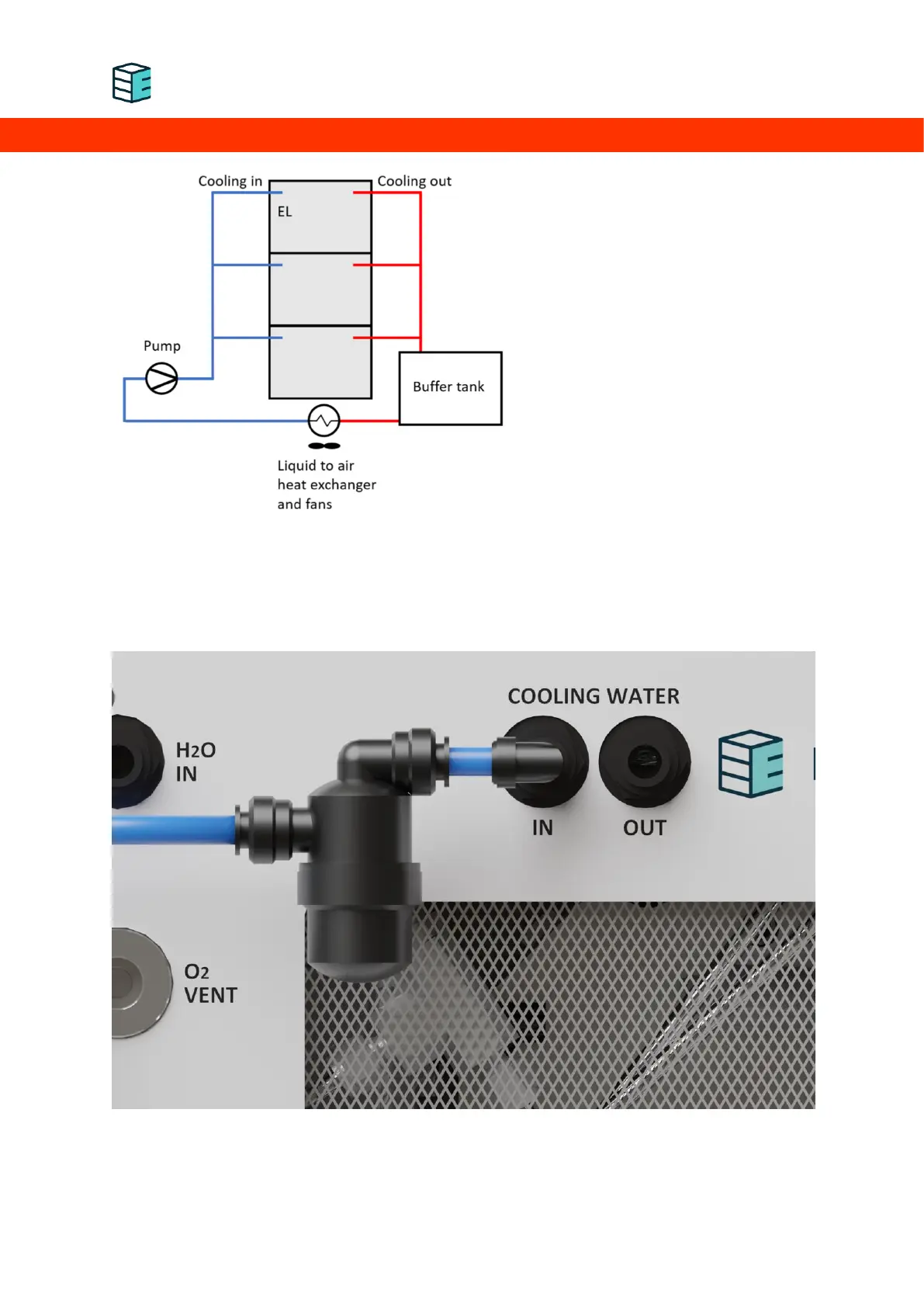

Enapter recommends to set up the

cooling loop according to the schematic

on the left. The return line should be

connected to a non-pressurised buffer

tank. This reduces back-pressure stresses

on the valve inside the device and will

prolong its lifetime. In case the waste heat

of the device will be used, a heat

exchanger for this purpose can be

integrated into this buffer tank. Connect

the pump downstream of the external

heat exchanger. When positioning it at a

lower part of the cooling circuit, gravity

can be used to feed the pump with water.

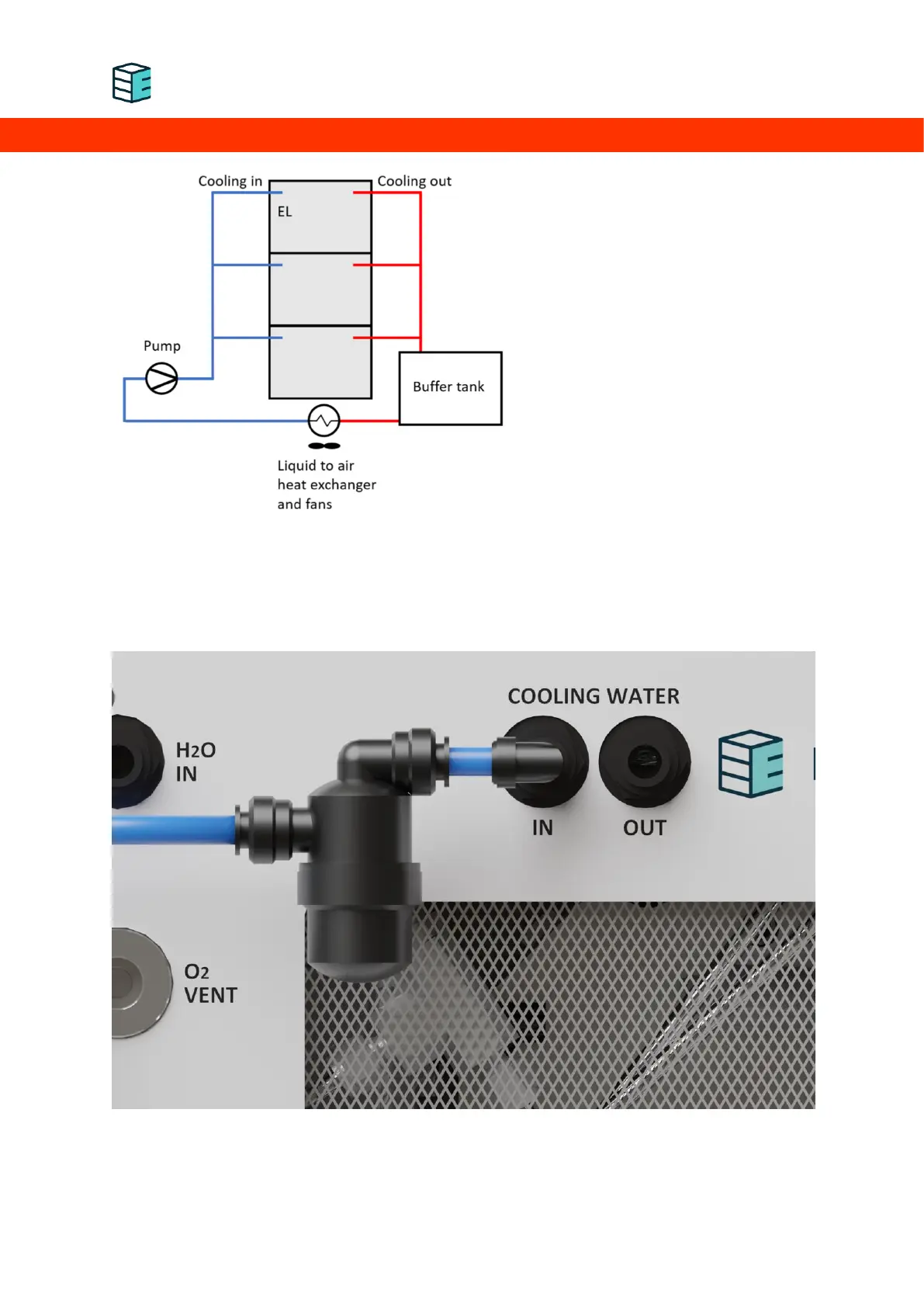

The cooling agent must be compatible

with 1.4301 stainless steel and LLDPE, free of particles and be usable at up to 60°C. Depending on the

ambient temperature, a frost protection agent may need to be added. To further increase device

reliability, install the filter supplied by Enapter on the cooling line inlet of the device.

EL LC with filter

Loading...

Loading...