The external heat exchanger must be sized to be able to transfer up to 1000 W out of each electrolyser

connected to the cooling loop.

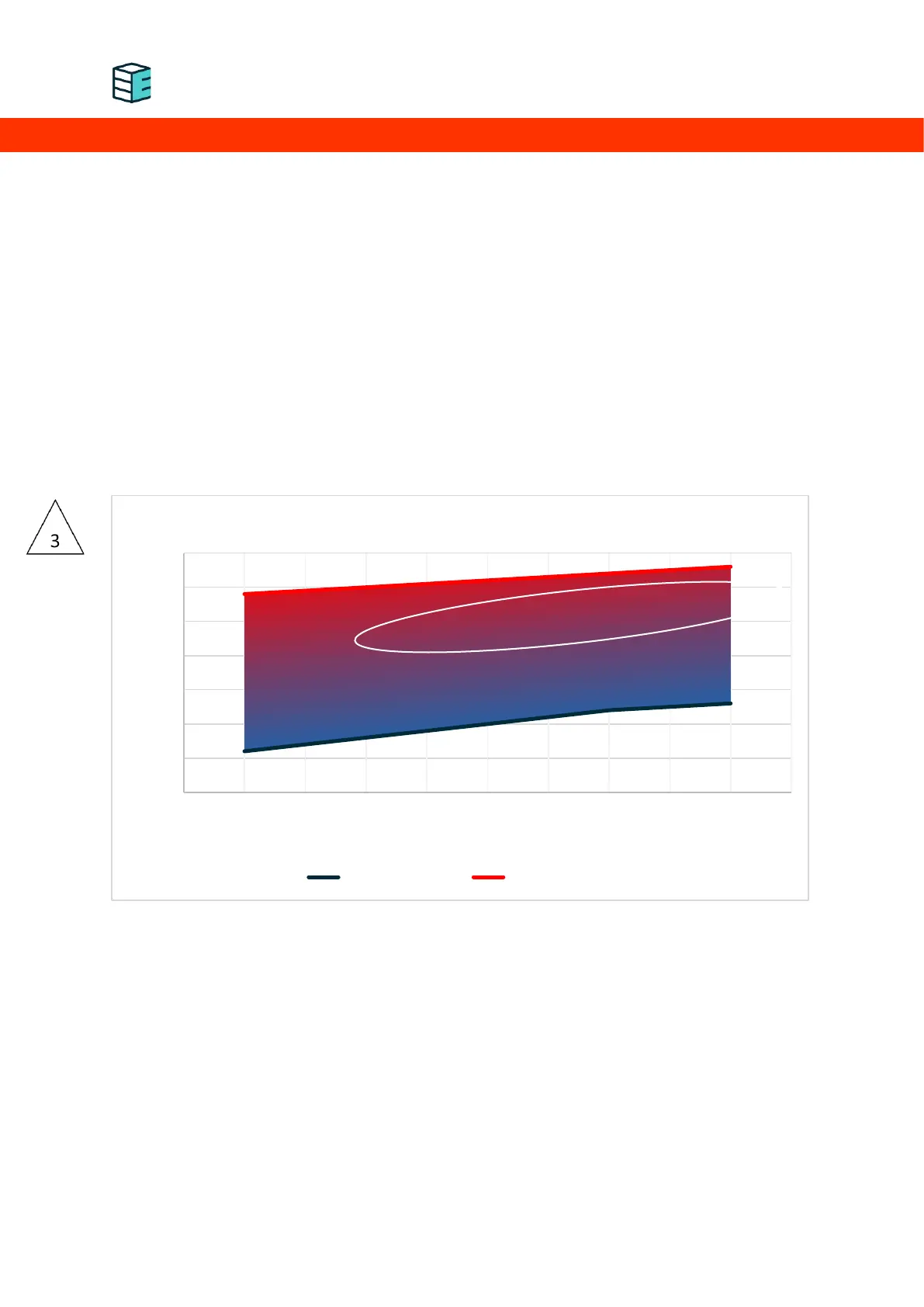

The graph below indicates the operating range of the cooling circuit in terms of allowable inlet

temperature of the cooling agent depending on its flow rate. The flow rates shown refer to the instant

flow rate per electrolyser. The cooling operation of the devices is intermittent so the average flow rate

will be lower. Keep in mind that these values are based on water. When using another cooling agent

with a different heat capacity, the required flow rate needs to be adapted accordingly. The pump used

must be suitable for intermittent operation and able to build up pressure against the closed solenoid

valves inside the electrolysers. The pump must be correctly sized to provide the necessary flow rate

against the pressure drop induced by the piping and electrolysers. The maximum flow rate through one

device is limited to 2 L/min by a flow restrictor. The pressure drop inside the device is up to 800 mbar

at 5 L/min. It is the operator’s responsibility to correctly size the liquid-liquid/liquid-air heat exchanger

and cooling agent pump.

Cooling loop operating range by temperature and flow rate

6

8

12

13

29

30

32

33

0

5

10

15

20

25

30

35

1 1,25 1,5 1,75 2

Coolant inlet temperature [

°C]

Flow rate [l/min]

Recommended coolant operation range

min temperature max temperature

Loading...

Loading...