Do you have a question about the Endress+Hauser RTA421 and is the answer not in the manual?

Details correct usage, emphasizing safe installation and operation.

Outlines the need for skilled and authorized personnel for installation, operation, and repairs.

Notes the manufacturer's right to update technical details.

Explains the contactor's function in monitoring industrial processes and analyzing signals.

Provides guidance on installation location, temperature, and protection from heat.

Presents the physical dimensions of the unit with a diagram.

Details the terminal assignments for power supply, loop power, and measurement signals.

Instructions for connecting the power supply, including isolator requirements.

Guidelines for connecting active current/voltage sources and passive current sources.

Illustrates the connection diagrams for Relay 1 and Relay 2 for alarm conditions.

Describes the operational indicator, fault indicator, measured value display, and relay status.

Explains how to navigate the menu, select functions, and enter parameters using the keys.

Details the input, limit, and operating parameter structure with their respective ranges.

Provides a step-by-step guide for setting up switchpoints and parameters using the Quick Set function.

Covers the setup of the analogue measured input, including input range selection.

Details setting the operating mode for alarm monitoring and defining switch thresholds.

Explains how to set hysteresis for switch thresholds to prevent rapid relay switching.

Describes how to set a time delay for set point conditions after the threshold is reached.

Illustrates the connection between switch threshold and hysteresis for safety modes.

Explains how to set and change a user code for accessing unit settings.

Provides an example of setting up for minimum and maximum level monitoring in a silo.

Details how to measure and display water depth in a deep well as a percentage.

Lists system fault messages, their causes, and recommended solutions.

Details specific system messages, causes like EEPROM defects, and troubleshooting steps.

Covers unit function, application area, and measurement principle.

Specifies input types, ranges, resolution, and output signals for relays and loop supply.

Provides accuracy figures and temperature drift for measurements.

Details installation angle, ambient temperature, climatic class, protection, and EMC immunity.

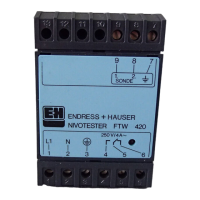

Describes physical construction, dimensions, weight, materials, and display elements.

Lists operational modes, switch threshold, hysteresis, time delay, and reaction time.

Specifies power supply ranges, consumption, and fuse details.

Provides input current limit and lists relevant certification marks and guidelines.

| Output | SPDT relay |

|---|---|

| Housing material | Aluminum |

| Protection class | IP66 |

| Process connection | G1/2" or 1/2" NPT |

| Approvals | ATEX, IECEx |