Section 6 Weld control 32

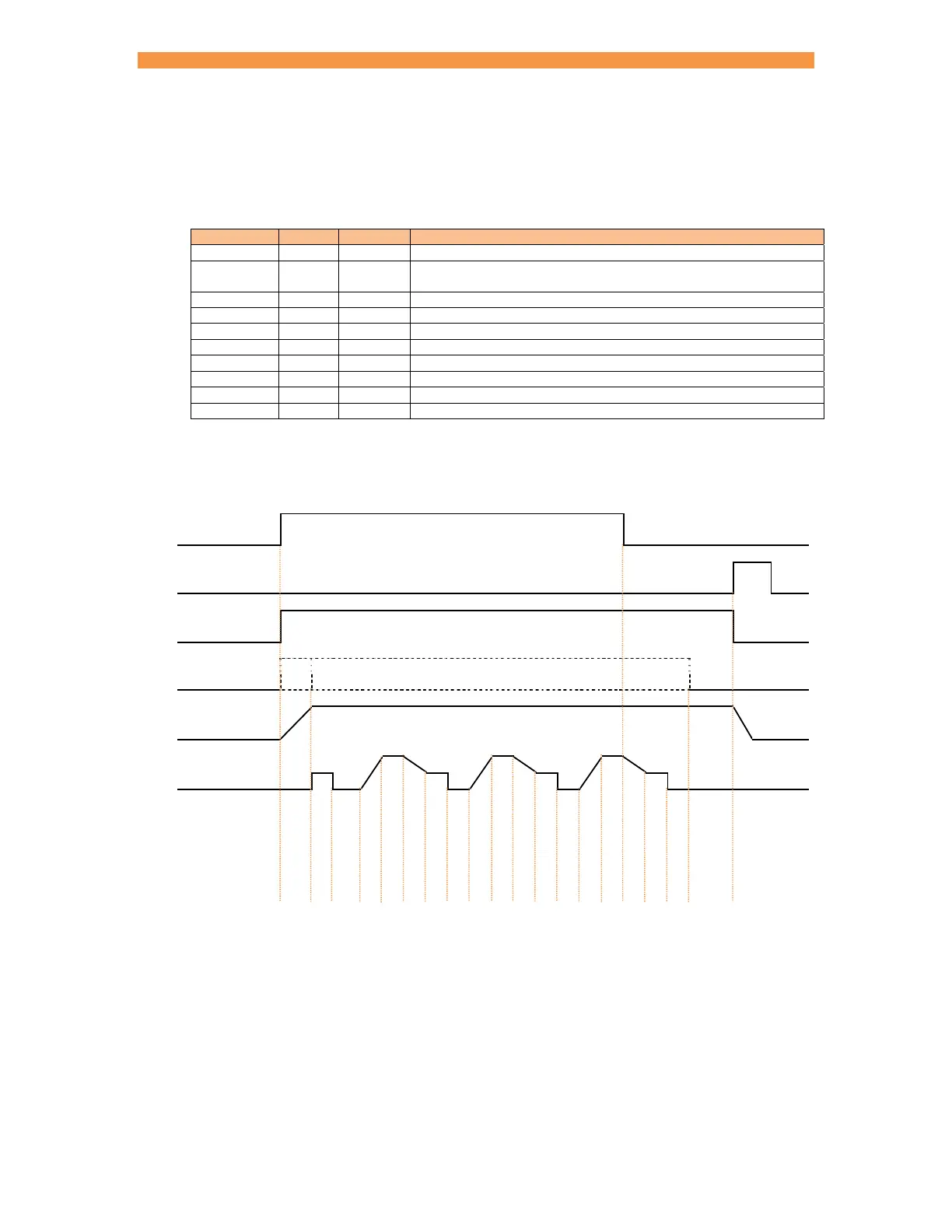

Seam sequence timing (extended feature)

The weld programs contain the following timing parameters. All parameters can be adjusted during the

sequence.

Parameter Units Range Description

Presqueeze ms 0 - 1999 The time for the electrodes to close onto the work piece.

Squeeze ms 0 - 1999 The time between the initial application of the electrode force and

the first application of welding current

Pre-heat

1

ms 0 - 1999 The pre-heat welding current is applied

Cool1

1

ms 0 - 1999 The material is allowed to cool with electrode force applied

Upslope ms 0 - 1999 Welding current is increased during this time

Main heat ms 0 - 1999 The main welding current is applied

Downslope ms 0 - 1999 Welding current is decreased during this time

Post-heat

2

ms 0 - 1999 The post-heat welding current is applied

Cool2 ms 0 - 1999 The material is allowed to cool with electrode force applied

Hold ms 0 - 1999 Electrode force continues after the welding current has finished

1

Pre-heat program option must be enabled to use this feature

2

Post-heat program option must be enabled to use this feature

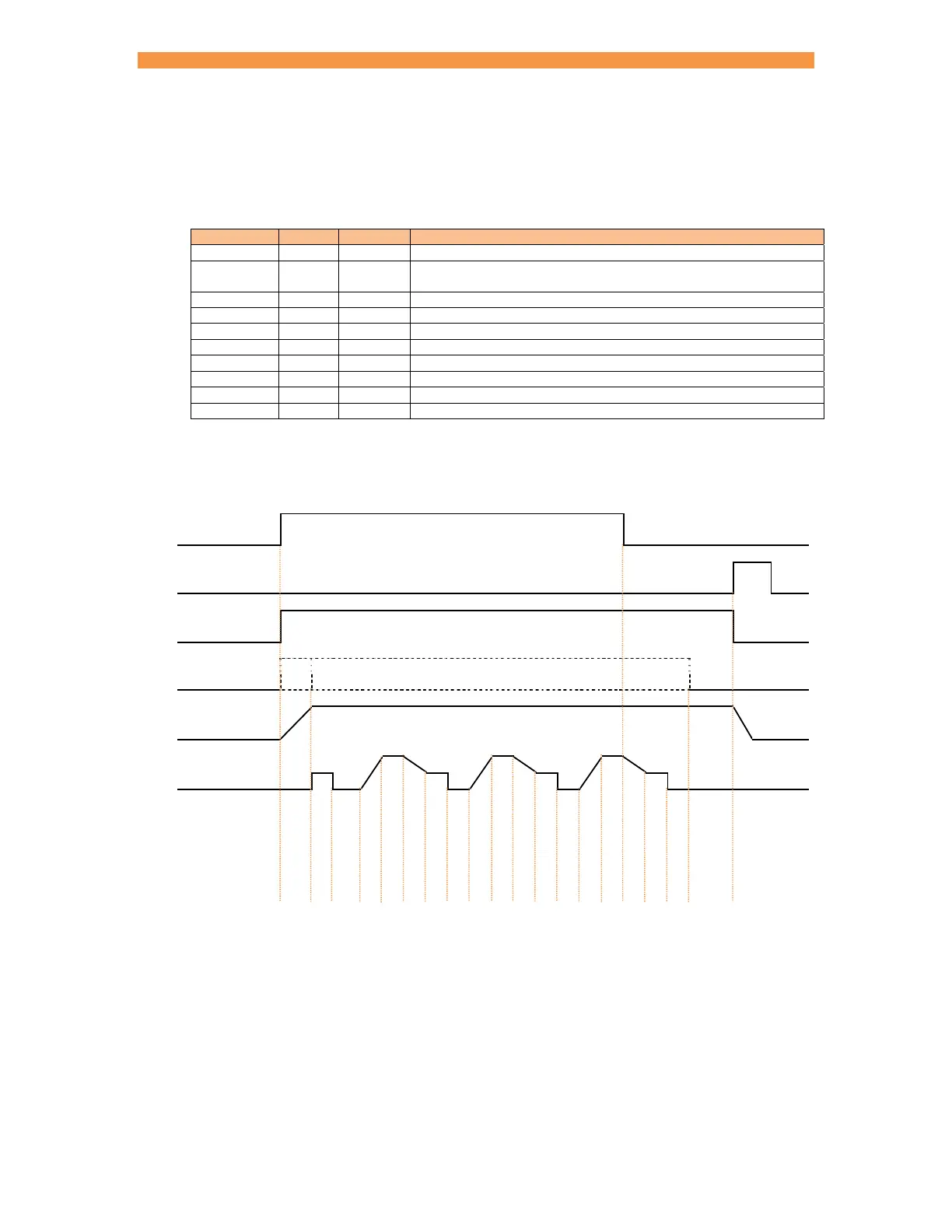

The diagram shows how the parameters control the sequence. (Presqueeze not shown)

Start input

1

EOS output

WAV output

Motor output

2

Force

Current

Interval

Squeeze

Pre-heat

Cool1

U

slo

e

Main hea

Downslo

e

Post-hea

Cool2

U

slo

e

Main hea

Downslo

e

Post-heat

Cool2

U

slo

e

Main hea

Downslo

e

Post-hea

Cool2

Hold

1

The intervals from Upslope to Cool2 repeat until the Start input is removed.

2

The operation of the motor output is determined by the 2

nd

stage test (Section 12 Configuration).

Loading...

Loading...