ENVIRO-TEC

46

FORM ET115.24-NOM11 (118)

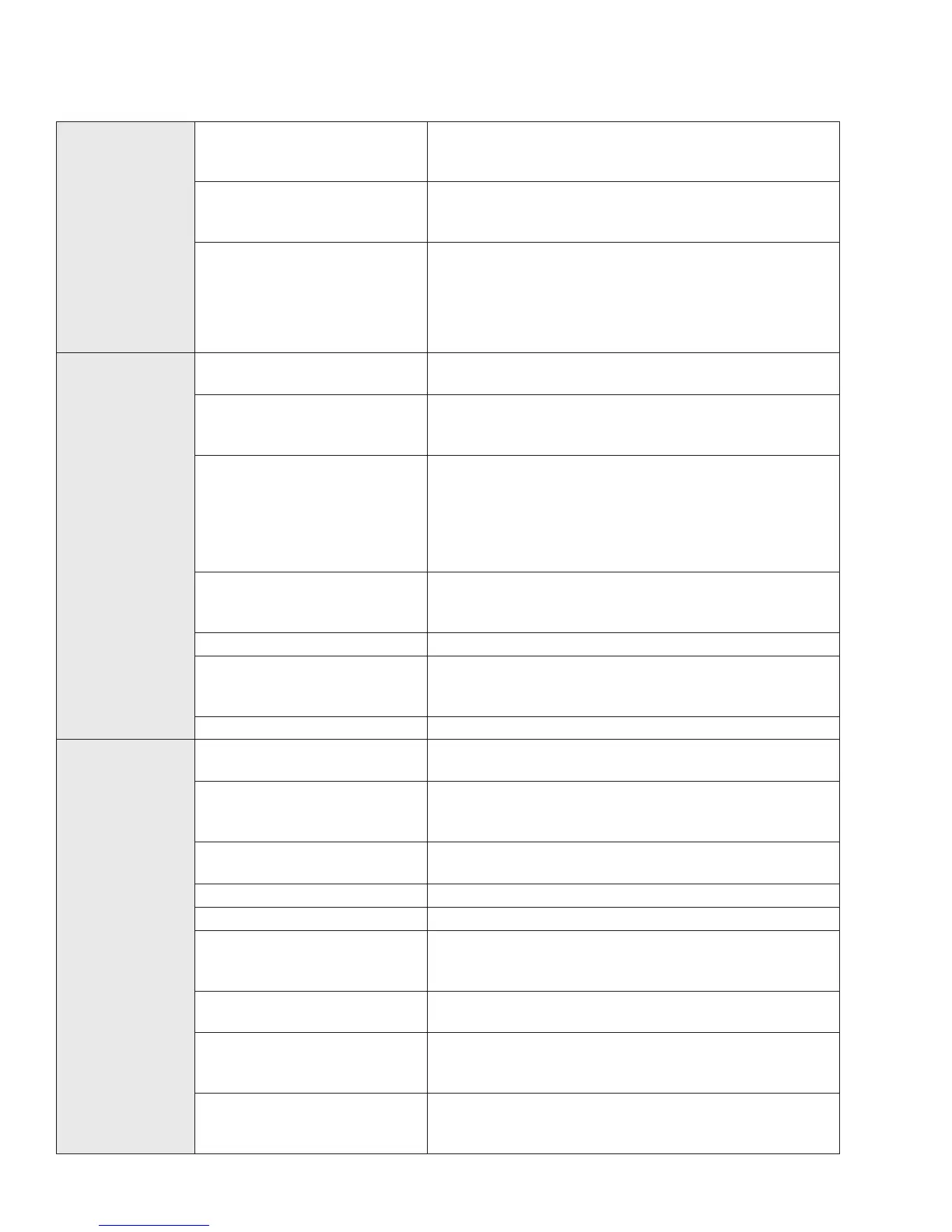

Electric Heat

will not operate

(cont’d)

CAUTION:

UNIT MAY BE

EXTREMELY

HOT. TAKE

GREAT

CARE WHEN

TROUBLE-

SHOOTING.

[Solid state relay] electric heat safety

contactor fault

Verify control voltage is at magnetic electric heat contactor control

coil terminals. If power is present at coil but contactor is not

actuated, replace contactor.

[Solid state relay] Solid State Relay

fault

Verify heating demand (control voltage) is at solid state relay

control terminals. If power is present but relay is not actuated,

replace relay.

[Solid state relay proportional

control] Heat controller fault

Verify DC control signal is present at controller input terminals.

Verify that output control voltage to solid state relay varies with

variation in input. Replace controller if not.

Electric Heat

shuts down

unexpectedly

CAUTION:

UNIT MAY BE

EXTREMELY

HOT. TAKE

GREAT

CARE WHEN

TROUBLE-

SHOOTING.

Loss of demand.

Verify that thermostat or control command signal is not dropping

out. Verify voltage is present at unit during demand for heat.

[24V units] Loss of demand.

Verify that signal from thermostat or control is not dropping out.

During demand, there needs to be 24V on 'W1' terminal of Fan

Relay board.

Primary limit switch tripped.

Verify no loss of demand to unit. Verify that voltage exists on

heater contactor during demand for heat. If demand reaches unit

but not contactor, primary limit is tripped. The primary limit

switch(es) will auto-reset once the unit cools down. If unit is hot,

wait for heater to cool down. This may take up to an hour. If limit

trips again, verify heater is not overheating.

Secondary limit switch tripped.

The secondary limit may be manually reset. If unit is hot, wat

for the heater to cool down. This may take up to an hour. Reset

switch(es). If limits trip again, verify heater is not overheating.

Loss of fan speed command. Heater will not operate if fan is not enabled.

Intermittent control device

Verify operation of any control device such as drain pan oat

switch, freeze stat, thermostat, etc. When in doubt, jumper out

and verify fan operation.

Loose wiring Verify and/or tighten all wiring connections.

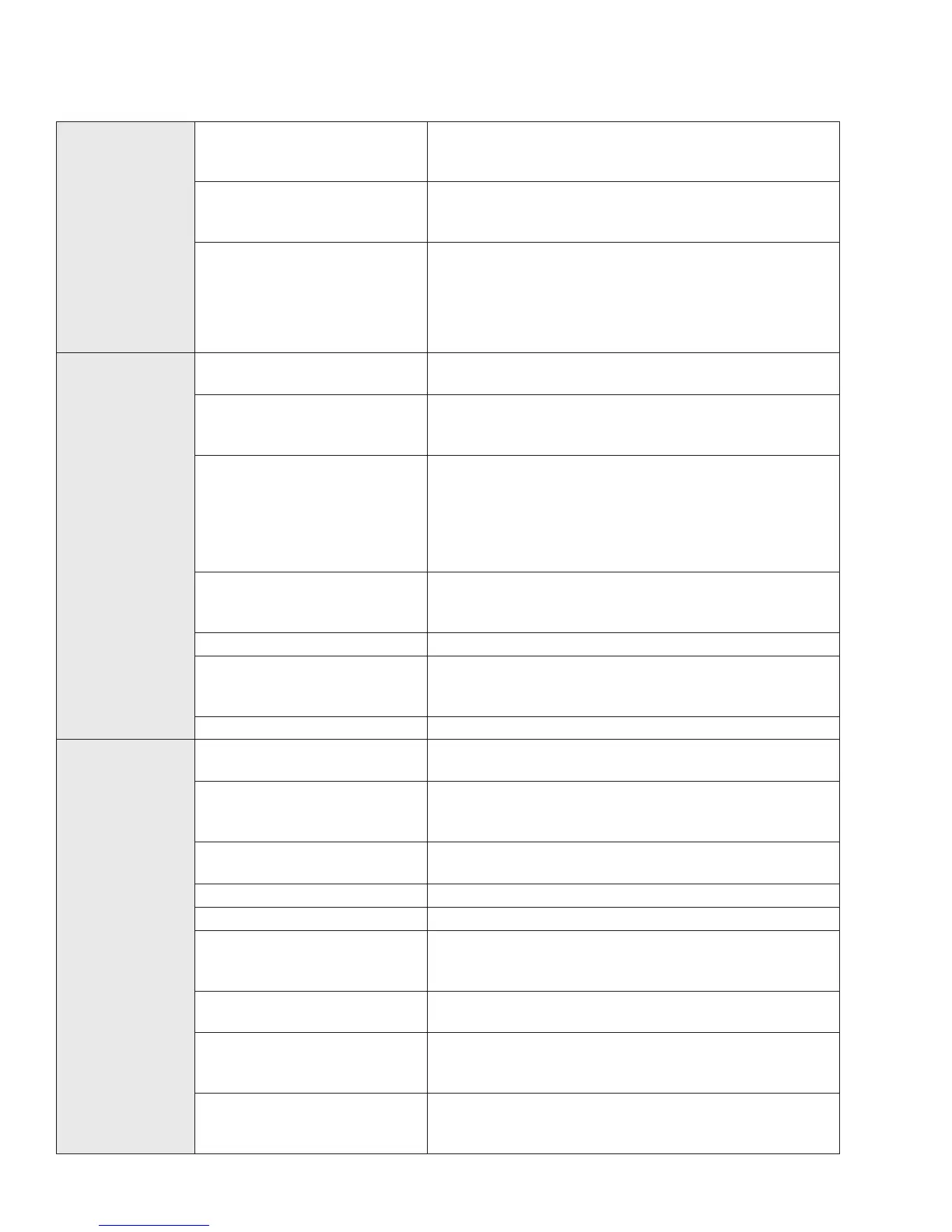

Electric heater is

overheating

CAUTION:

UNIT MAY BE

EXTREMELY

HOT. TAKE

GREAT

CARE WHEN

TROUBLE-

SHOOTING.

Insucient airow

Verify that airow is sucient to provide a minimum of 70 CFM

per kW of electric heat.

Improper duct connections

Electric heaters require even airow across the face of the heater

in order to operate properly. Verify ductwork is installed per

SMACNA and ASHRAE guidelines.

Obstructed ductwork

Verify no obstructions. Verify all dampers are full open while

fan operates.

Intermittent fan Verify fan motor runs continuously, providing even airow.

Incorrect voltage applied. Verify proper voltage to unit per unit label.

Improper wiring connections

Verify wiring to schematic. If Fan Coil Relay board present, verify

all jumpers and harnesses installed. Refer to Fan Coil Relay Board

Troubleshooting Guide.

Damaged heater elements

Remove power from unit. Access the heater compartment. Verify

heating elements are undamaged.

Shorted magnetic heater contactor

Remove thermostat or control command signal. Verify no control

voltage to heater contactor. If electric heat continues to operate

and all wiring has been veried, replace contactor.

[Solid state relay] Shorted solid

state relay

Remove thermostat or control command signal. Verify no control

voltage to solid state relay. If electric heat continues to operate

and all wiring has been veried, replace solid state relay.

Loading...

Loading...