ENVIRO-TEC

4

FORM ET115.24-NOM11 (118)

During and after installation, special care must be taken

to prevent foreign material such as paint, plaster, and

drywall dust from being deposited in the drain pan or

on the motor or blower wheels. Failure to do so may

have serious adverse eects on unit operation and in

the case of the motor and blower assembly, may result

in immediate or premature failure. All manufacturers’

warranties are void if foreign material is allowed to be

deposited on the motor or blower wheels of any unit.

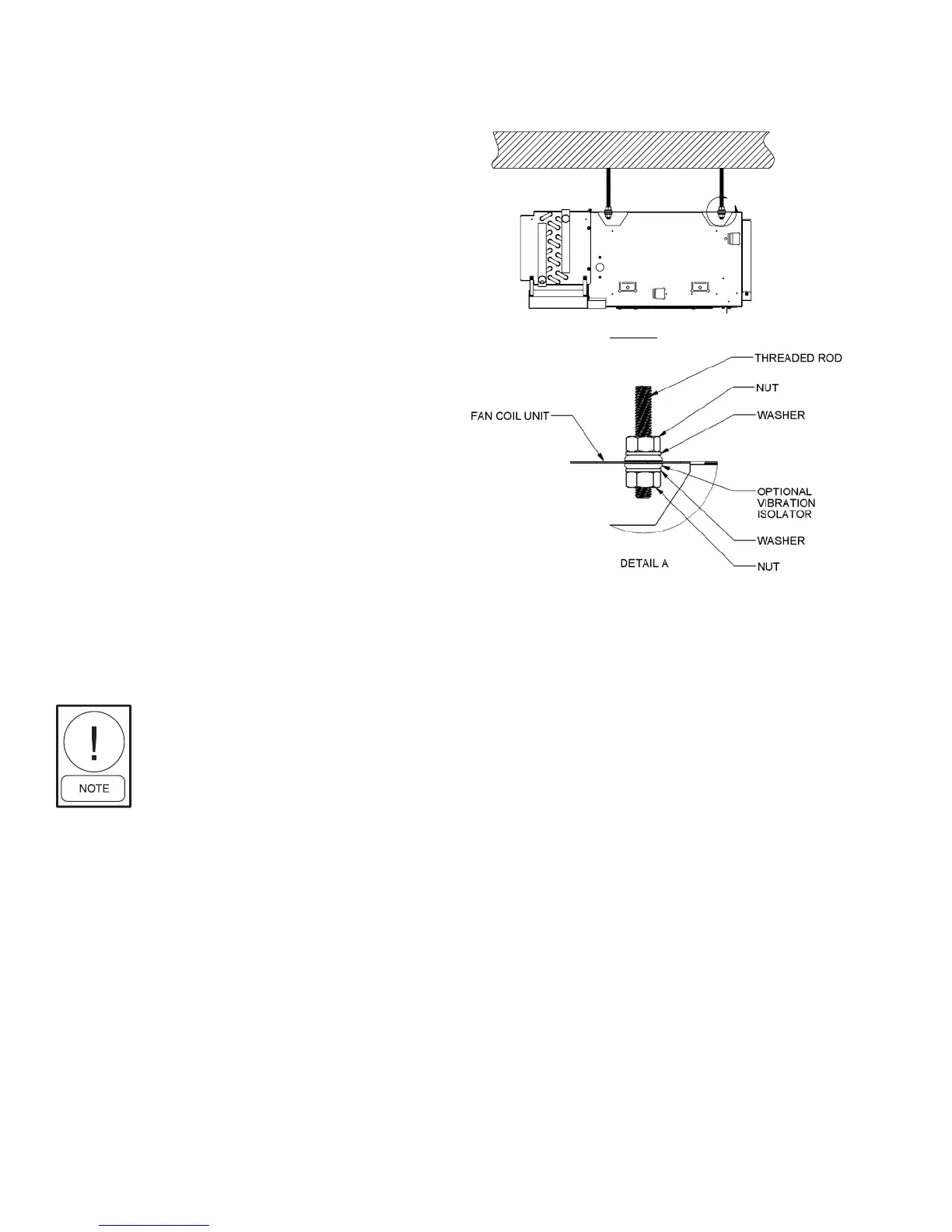

Some units and/or job conditions may require some form

of temporary covering during construction.

While the manufacturer does not become involved

in the design and selection of support methods and

components, it should be noted that unacceptable system

operating characteristics and/or performance may result

from improper or inadequate unit structural support.

In addition, adequate clearance must be provided for

service and removal of the equipment and its accessory

components. Anchoring the equipment in place is

accomplished by using the mounting points provided

and positioning the unit to maintain the unit on a LEVEL

plane. The drain pan is internally sloped toward the

outlet connection. Care must be taken to insure that

the unit drain pan does not slope away from the outlet

connection. All units are supplied with integrated hanger

brackets with optional grommet isolators and brass

inserts for use with 3/8" all thread hanger rod.

The unit’s drain pan is factory sloped toward the

drain connection when the unit is

installed level and plumb.

A

DETAIL A

THREADED ROD

NUT

VIBRATION ISOLATOR

NUT

WASHER

WASHER

FAN COIL UNIT

SIDE VIEW

NOTES:

1. ALL BENDS ARE 90

UNLESS OTHERWISE SPECIFIED.

2. ALL FORMED DIMENSIONS ARE OUTSIDE DIMENSIONS.

3. FEATURE QUANTITIES MAY VARY FOR DIFFERENT

CONFIGURATIONS.

TYPICAL CEILING INSTALLATION

Figure 1: Typical ceiling installation

Loading...

Loading...