REV. 10/2021

5D

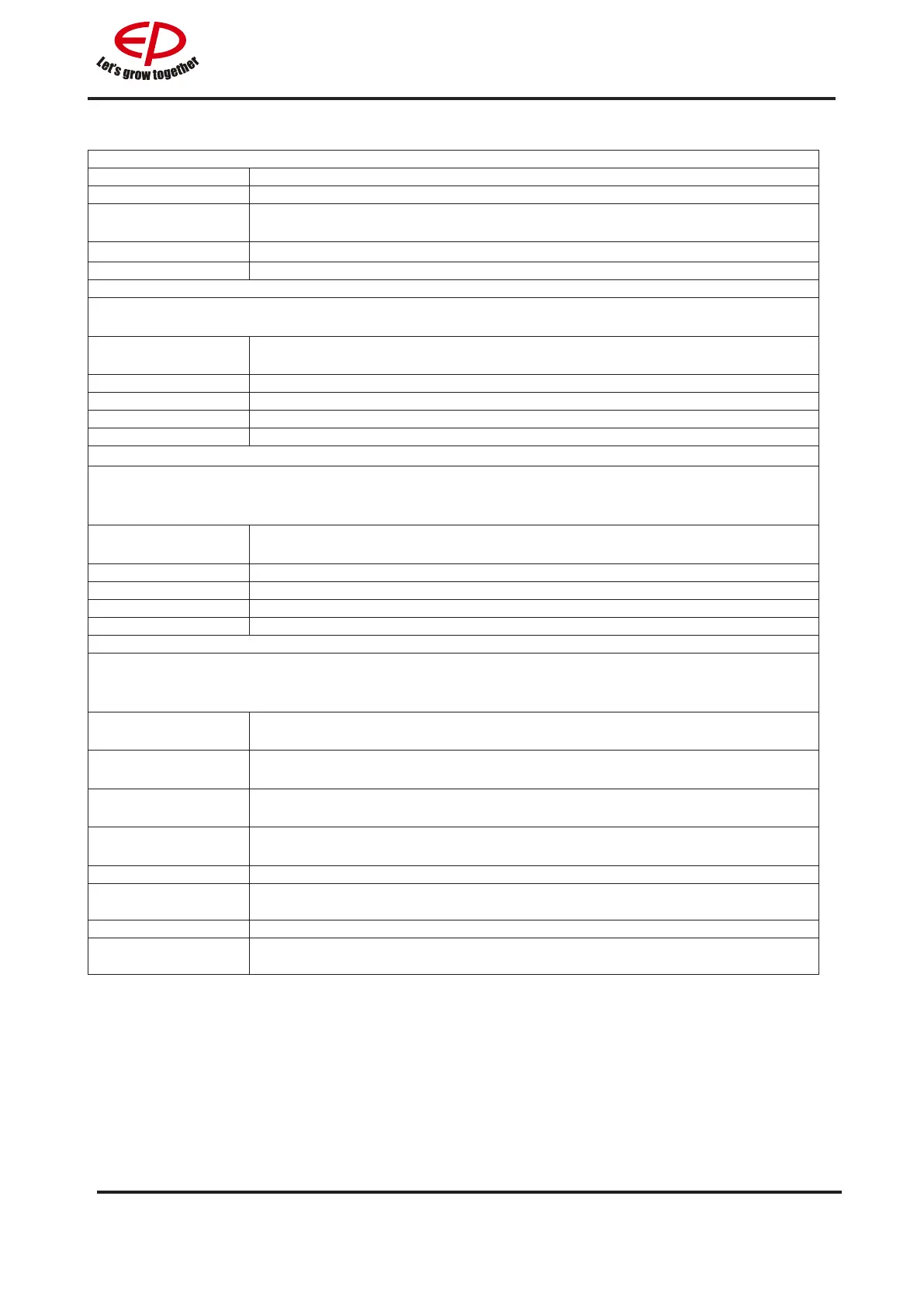

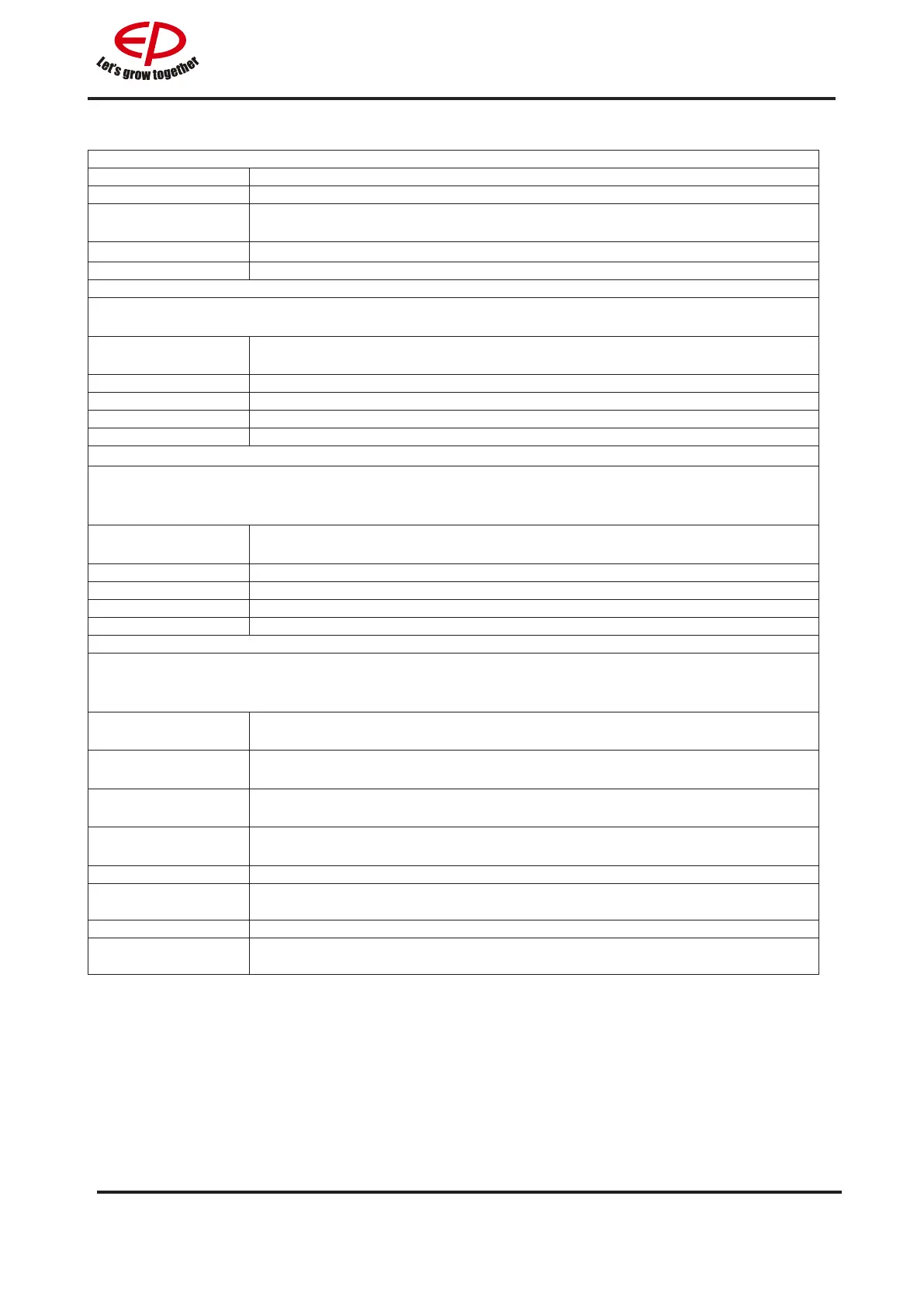

1.2 Maintenance table

50-hour/7-Day maintenance

1 Check the functions of the operation switches and display.

2 Check display equipment, alarm system and safety devices.

3 Check the emergency reverse switch, reverse braking, emergency

disconnect switch and regenerative braking.

4 Check tiller steering functions.

5 Check the drive wheel and load wheel for worn or damage.

250-hour/2-month maintenance

After operating for 250 hours in total, the truck should also be maintained according to the

following procedures in addition to the 50-hour maintenance mentioned above

7 Inspect where there is any damage in the cables and whether the

terminals are reliable.

8 Inspect whether there is any screw losing or slipping out.

9 Inspect whether there is any abrasion or damage in the oil pipes.

10 Inspect where is any leakage in the hydraulic oil.

11 Clean and lubricate the contact surface with grease.

500-hour/3-month maintenance

After operating for 500 hours in total, the truck should also be maintained according to the

following procedures in addition to the 250-hour maintenance and 50-hour maintenance

mentioned above

12L Check that the battery cable connections are tight and grease the battery

poles if necessary.

13 Check if the signs are legible and complete

14 Inspect and fasten the controller and other electrical apparatus elements

15 Adding gear oil or grease.

16 Check the oil level in the oil tank.

1000-hour/6-month maintenance

After operating for 1000 hours in total, the truck should also be maintained according to the

following procedures in addition to the 50-hour maintenance,250-hour maintenance and 500-

hour maintenance mentioned above

17 Inspect whether there is any abnormal sound or disclosure of the gear

box.

18 Inspect the abrasion situations of the driving wheel/bearing wheel and

please timely replace seriously abraded ones.

19 Inspect whether all the oil pipes, pipelines and joints are reliably

connected and whether all the sealing elements are reliable.

20 Inspect the air gap of the electromagnetic brake, and if the air gap is

larger than 0.4mm, please replace the friction plates.

21

Check the frame for damage.

22

Inspect where there is any damage in the oil cylinders and whether

corresponding installations are reliable

23

Inspect and check the hydraulic lter,replaced if necessary.

24

Check cylinder block and piston for damage and ensure that they are

properly sealed and secured.

Loading...

Loading...