SE Group Confidential (Related Staff Only)

Adjustment Details of Adjustments 66

SC-P600 Revision D

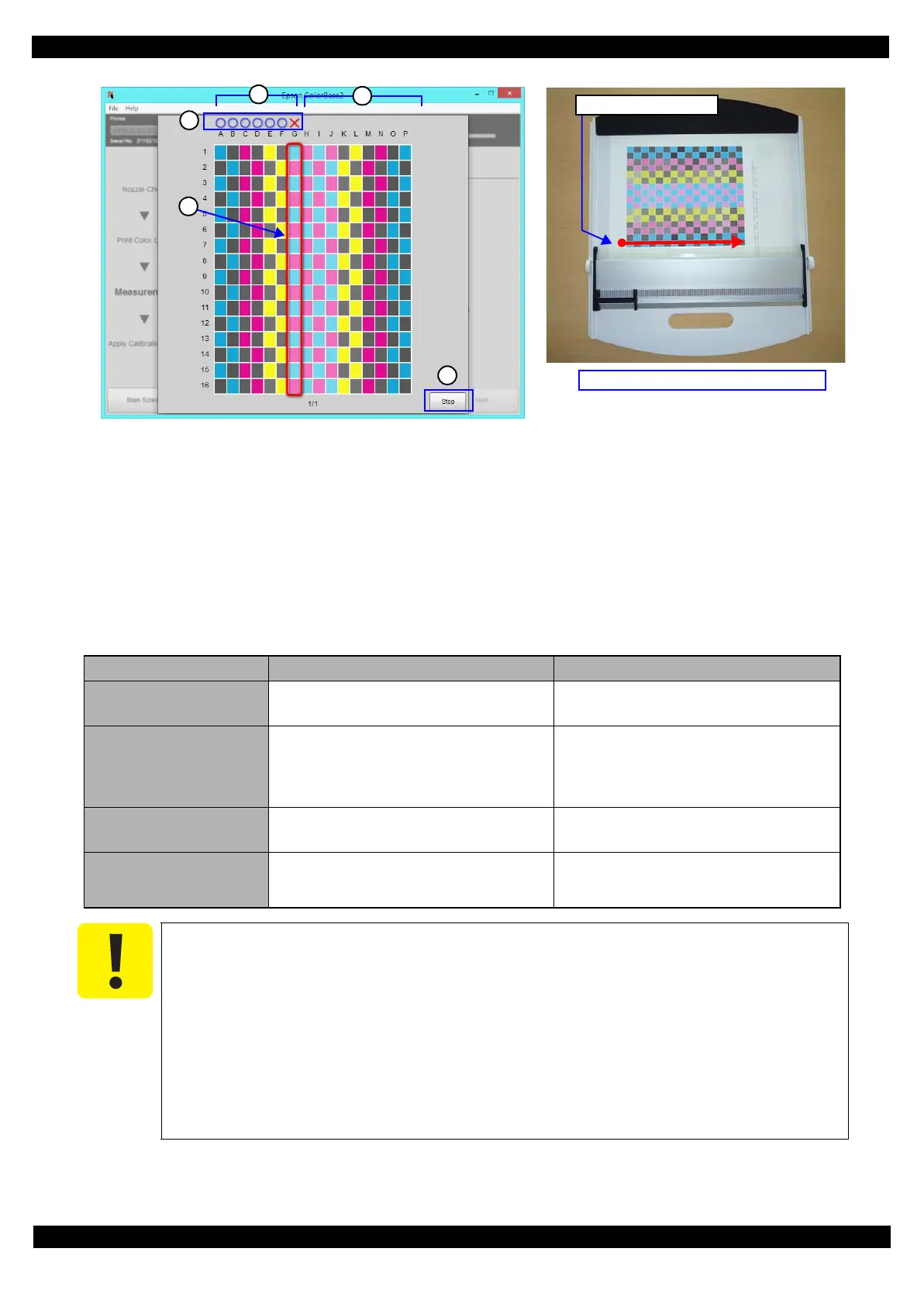

Figure 2-37. Starting the Color Measurement

x

Table 2-8. Limitations of the calibrator

i1Pro i1Pro2

Measurement start

point

Upper left on the color chart Upper left on the color chart

Measuring direction

In the direction of the arrow in Figure 2-35

only. An error occurs if scanned in the reverse

direction.

Outward (tungsten light): In the direction of

the arrow in

Figure 2-35

only.

Inward (UV light): In the reverse

direction from the outward scanning

Times of measurements

per row

Once Two times (one cycle)

When the

measurement fails

Perform the measurement of the failed row.

Cannot go on to the next row until the

measurement is successfully complete.

Perform the measurement of the failed row.

Cannot go on to the next row until the

measurement is successfully complete.

During color measurement, do not allow the calibrator to rub against unmeasured

patches on the chart.

Prevent the ruler and calibrator from coming off the chart sheet during color

measurement. Doing so will cause incorrect color measurement.

Do not press the calibrator to the chart too strongly, otherwise the patch may be

damaged.

If “X” appears repeatedly and the measurement fails continuously, the measured color

value may be far out of the standard range. In that case, end the measurement and go to

the troubleshooting below.

(1)

Color measurement

“complete” rows

Measured rows (starting from the left)

(2)

Color measurement

“not complete” rows

Rows to be measured (up to the right end)

(3)

Cursor Automatically moves right when color measurement of a row is complete.

(4)

Measurement result “O” appears if the color value is within the normal range. Otherwise or the number of patches is

not matched, “X” appears.

(5)

Stop button Discards the current measurement result and go back to the previous window before measurement.

Measurement start point

3

5

4

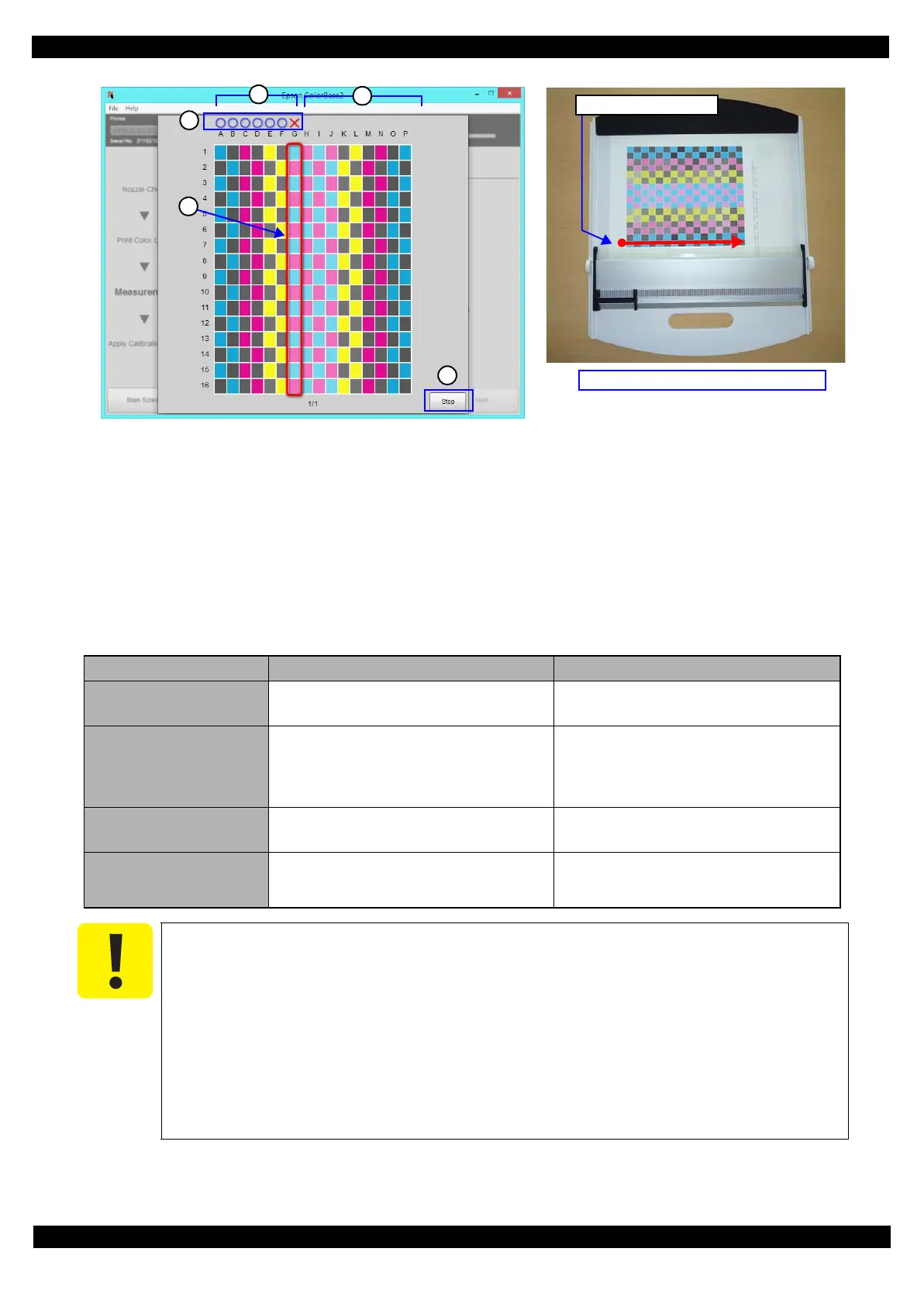

Orientation of the chart during measurement

1

2

Loading...

Loading...