7.8 Cleaning/replacing the tensioning wheel

at the sealing head

- 66 -

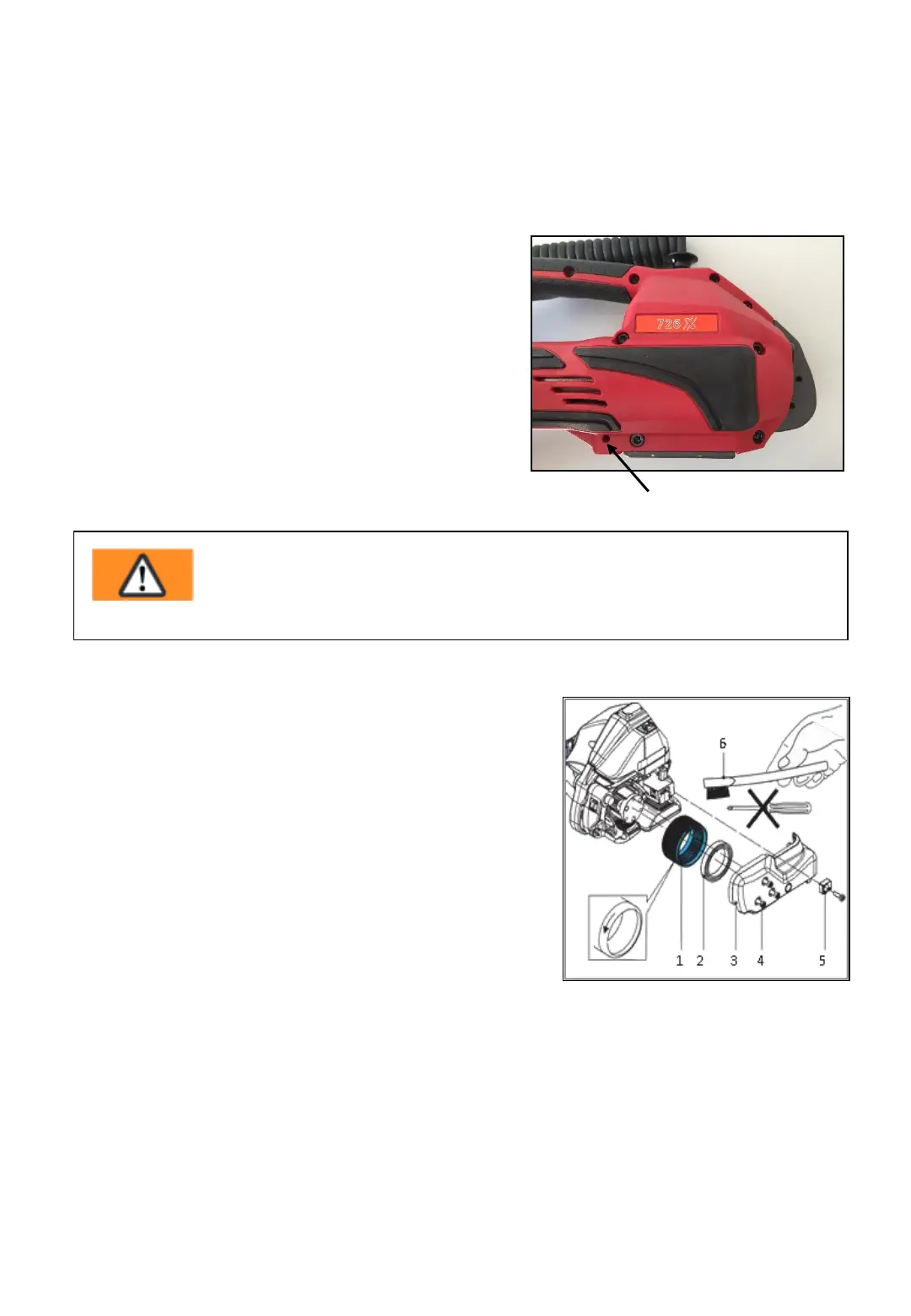

Cleaning the tension wheel with

disassembling / replacing the tension wheel

Release 4 cylinder screws (Torx) (4),

remove strap guide rear (5) and side cover (3).

Remove tension wheel (1) carefully.

Remove ball bearing (2) from tension wheel.

Clean the tension wheel with compressed air.

If the tension wheel teeth are covered with

heavy dirt they must be cleaned carefully with the wire brush (6)

supplied.

Check tension wheel for worn teeth. If a few teeth are broken, replace

tension wheel (observe direction, see arrow).

Fig. 101

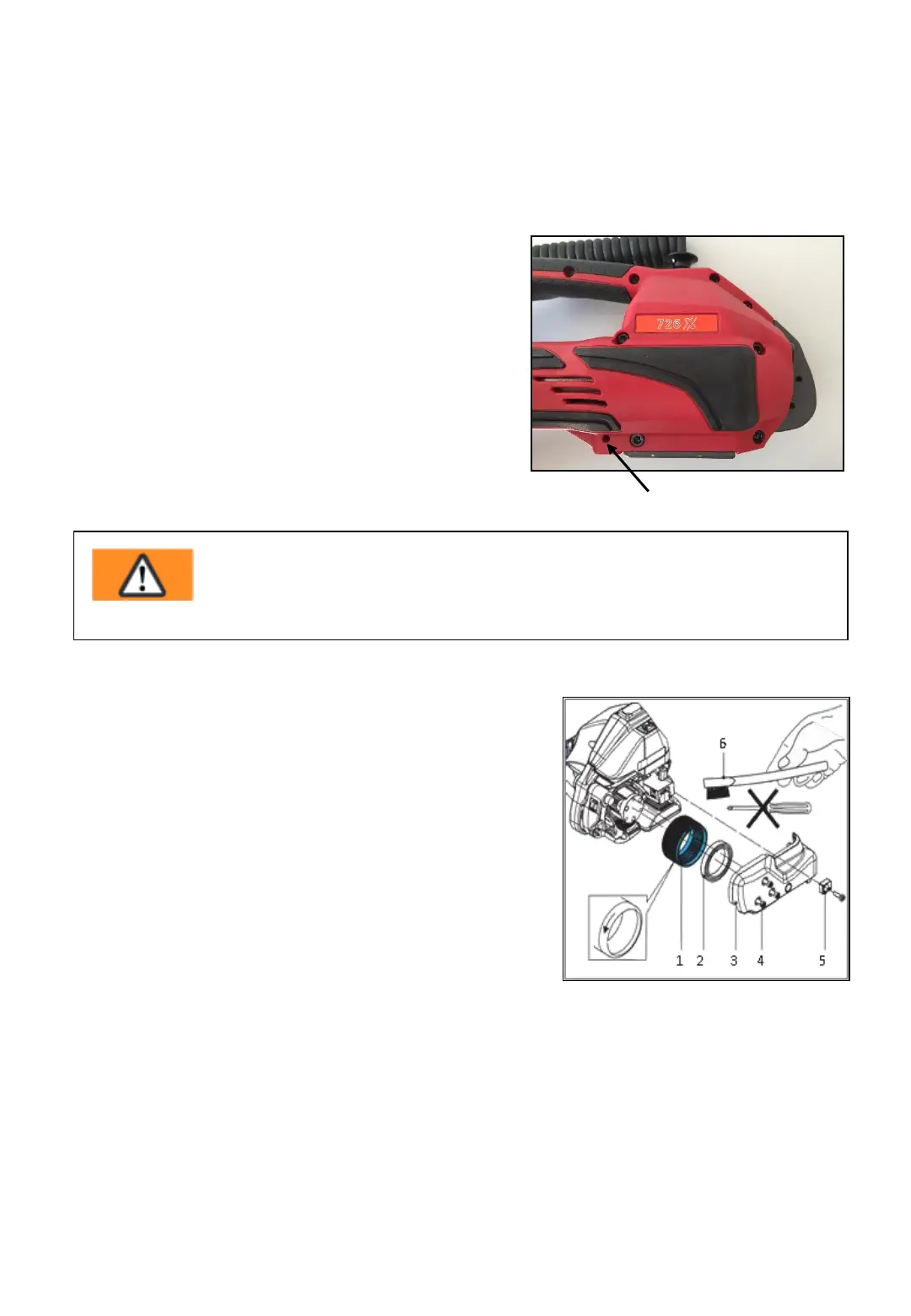

Cleaning the tension wheel without

disassembling

There is an access hole (100a) in the

protection cover below the motor. The

tension wheel and the tooth plate can be

cleaned with compressed air through this

access hole.

When heavily soiled, the tension wheel

has to be disassembled.

Fig. 100

100a

Warning !

Wear eye protection when cleaning with compressed air!

Loading...

Loading...