31

3.6 Work and Earth Connections

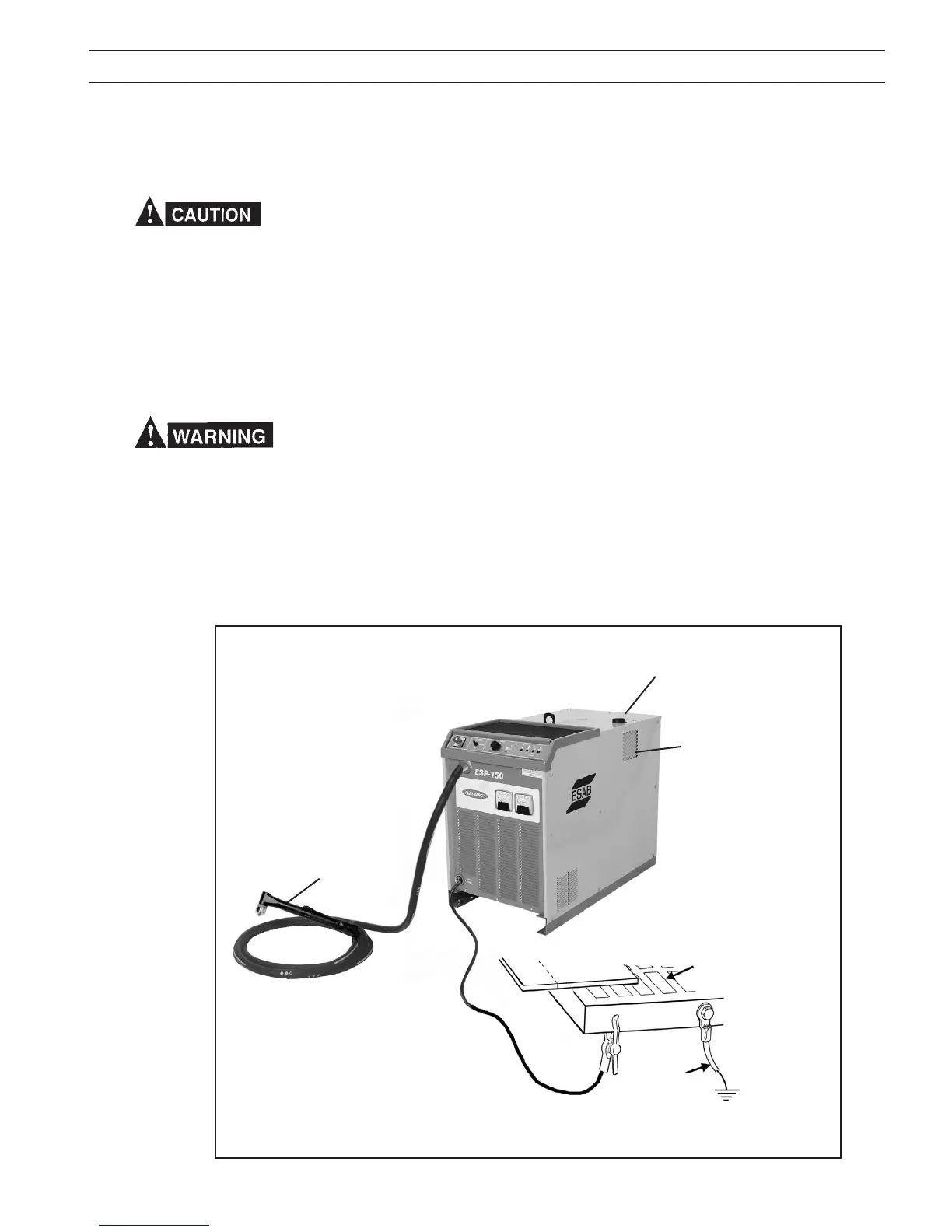

1. Connect terminal lug end of the work cable assembly to stud on lower left corner

of front panel. Nut should be wrench tight. (Fig. 15). Electrically connect work

cable to work piece. The connection must be made to a clean, exposed metal

surface free of paint, rust, mill scale, etc. (Fig. 15).

2. Make sure workpiece is connected to an approved earth ground. Use copper

ground cable equal to or larger than the power supply chassis ground listed in

Table 1.

3.7 Torch Coolant Preparation

1. Remove the cap from the coolant lter tank. Fill coolant tank with 2 gallons (7.5

liters) of plasma system coolant (P/N 156F05) - supplied with the package. The

coolant also provides antifreeze protection down to -34°.

Due to high electrical conductivity, use of tap water or commercial antifreeze is

NOT recommended for torch cooling. Use of tap water can result in algae growth

in the water cooler and torch. Automotive type antifreeze will adversely aect

starting and will form deposits in the torch that will cause damage.

2. With installation completed, check all gas and coolant ttings for leaks using a

standard solution.

TORCH COOLANT FILL

ACCESS

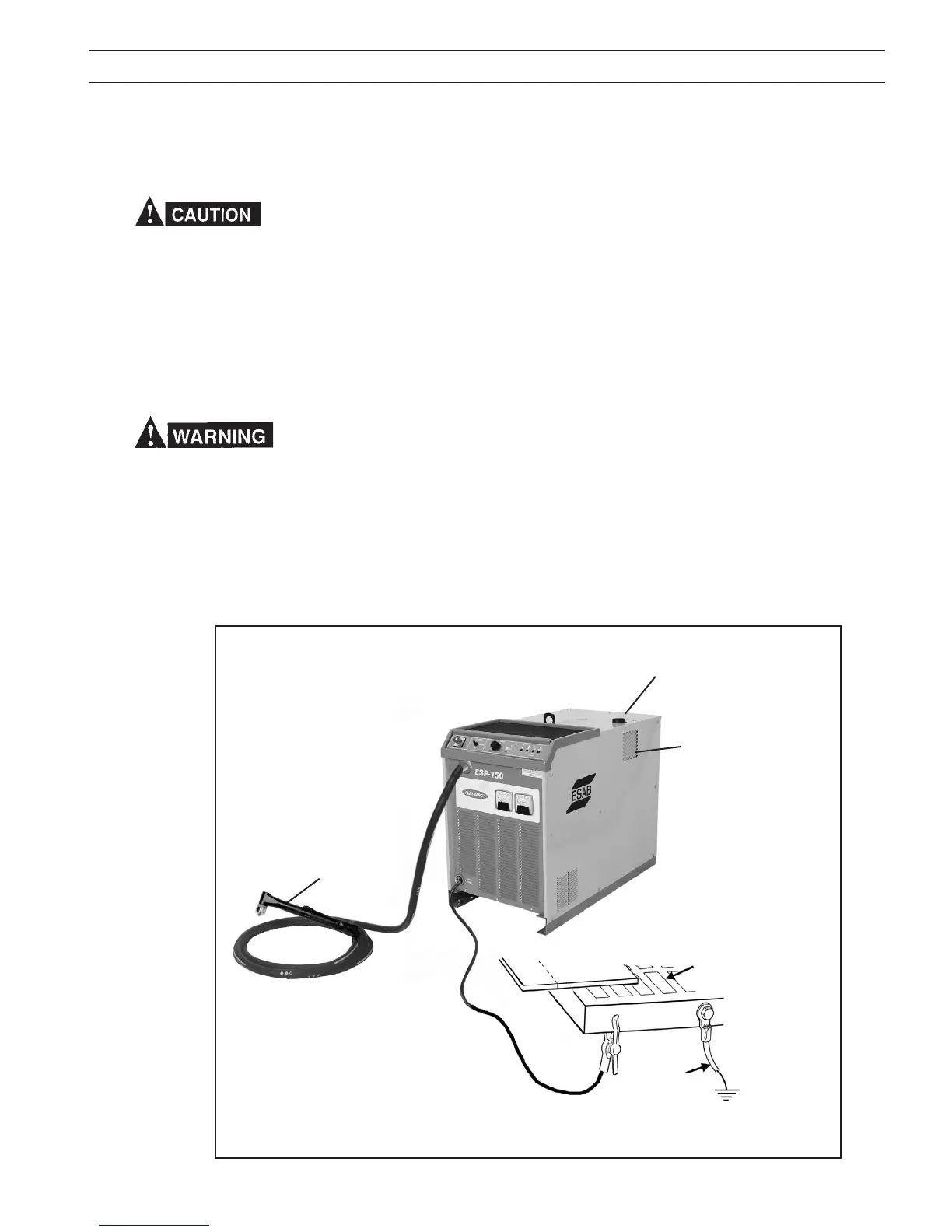

Fig. 15 - Access for lling Torch Coolant Tank

Operating the unit without coolant will

cause permanent damage to coolant

pump.

Do not use commercial antifreeze or tap

water. Equipment will malfunction and

damage will occur.

PT-26

Grounded

Work

Table

Earth

Ground

Work Cable -

25 ft. - 23120589

50 ft. - 23120590

LEVEL INDICATOR

SECTION 3 INSTALLATION

Loading...

Loading...