37

4.4 Stando and Cut Quality

Stando (Arc Voltage) has a direct inuence on cut quality and squareness. It is recom-

mended that prior to cutting, that all cutting parameters are set to the manufacturer’s

suggested conditions. Refer to the Process Tables for recommendations. A sample

cut should be made using actual part material followed by close examination of

the part.

If the cut face of the part has excessive bevel or rounded top edge, it may be that the

stando is set too high. When stando is controlled by an arc voltage height control,

reducing the arc voltage setting will reduce the stando.

Lower the stando until the excessive bevel or rounded top edge disappears. The

characteristics of plasma cutting hinder production of a perfectly square cut. On

material thicknesses of 1/4 inch or greater, a stando too close may result in a nega-

tive cut angle.

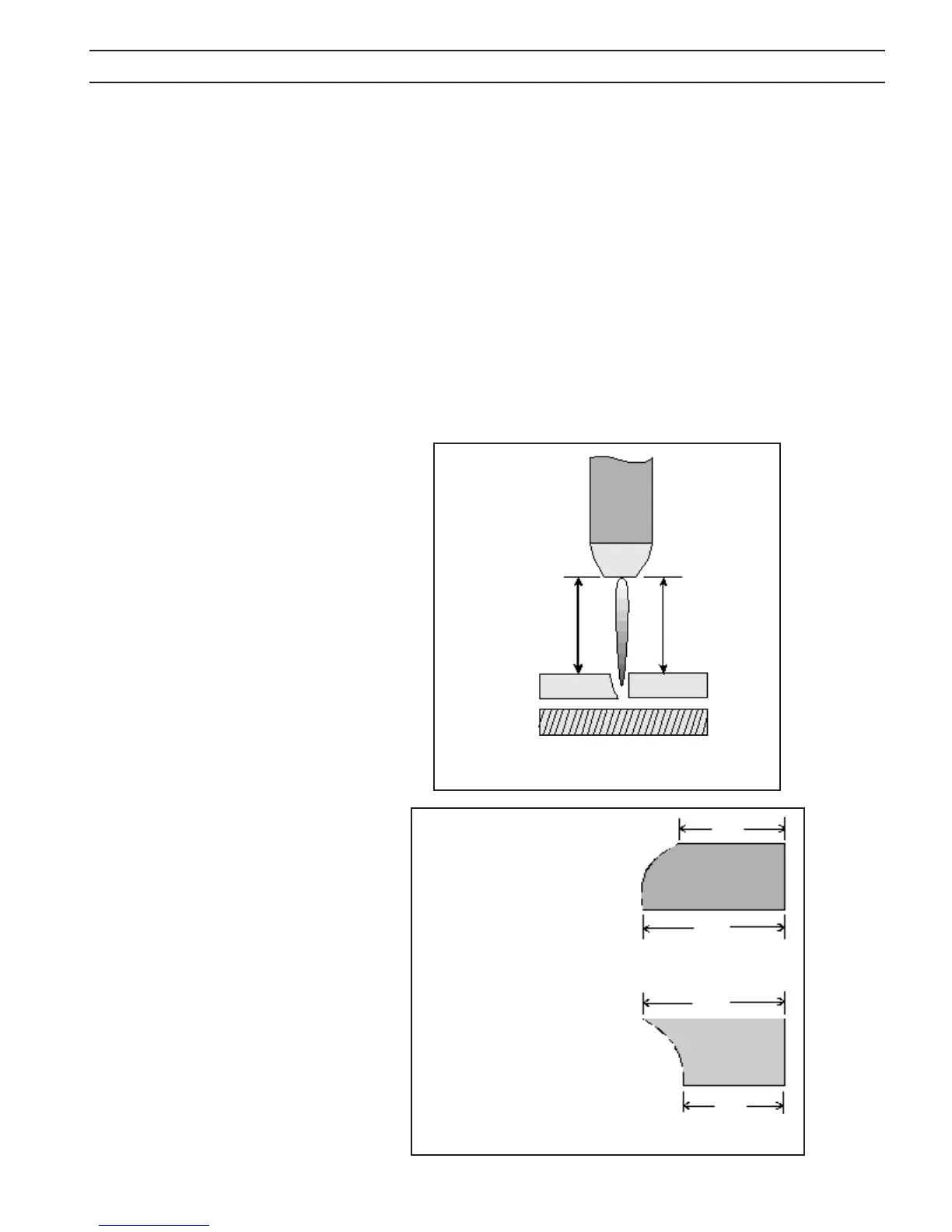

Fig. 18 - Cut Angle

Bottom dimension “B”

is less than dimension

“A”

NEGATIVE (-) CUT ANGLE

Bottom dimension “B”

is greater than dimen-

sion “A”

POSITIVE (+) CUT ANGLE

A

B

A

B

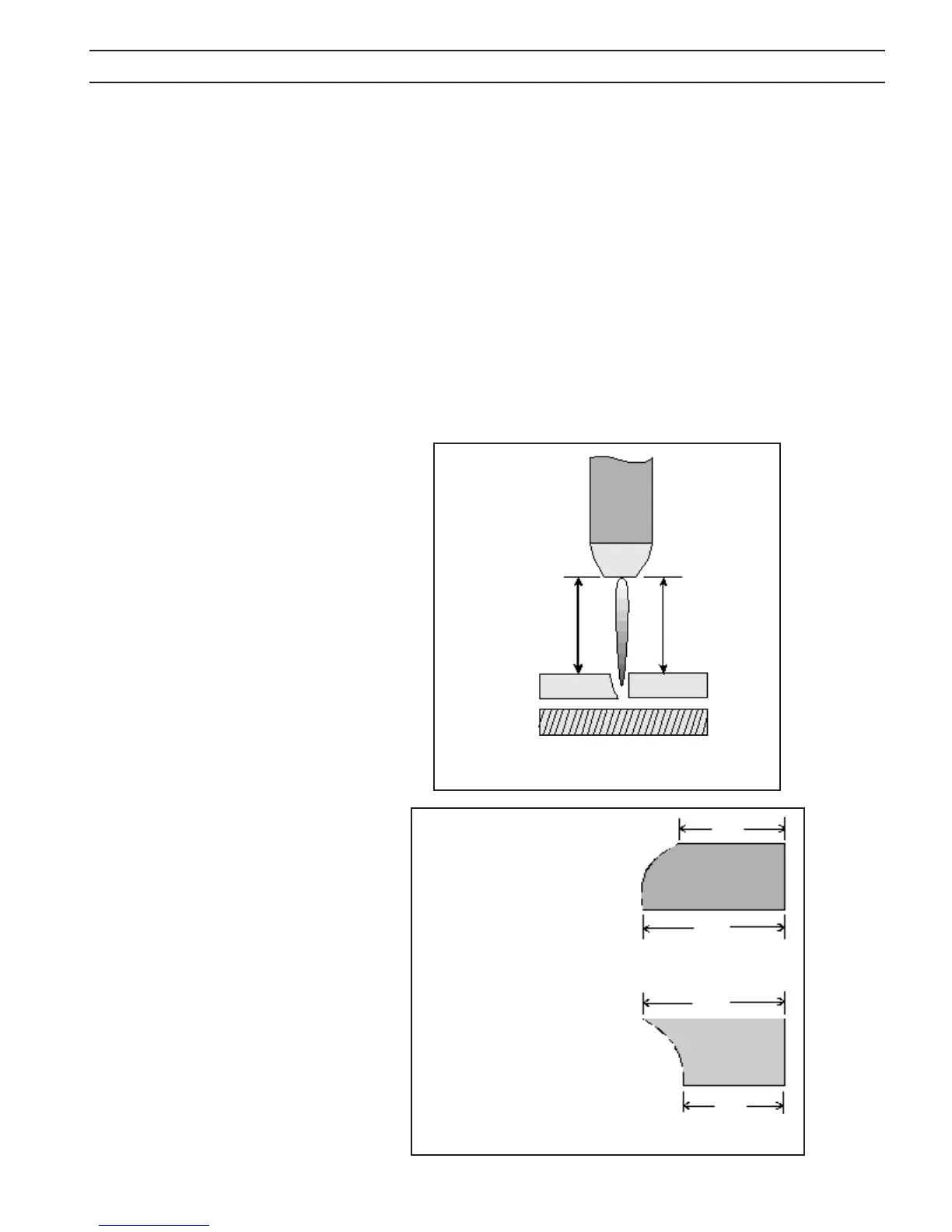

Fig. 17 - Cut Quality

LAG LINES

ARC

VOLTAGE

STANDOFF

SECTION 4 OPERATION

Loading...

Loading...