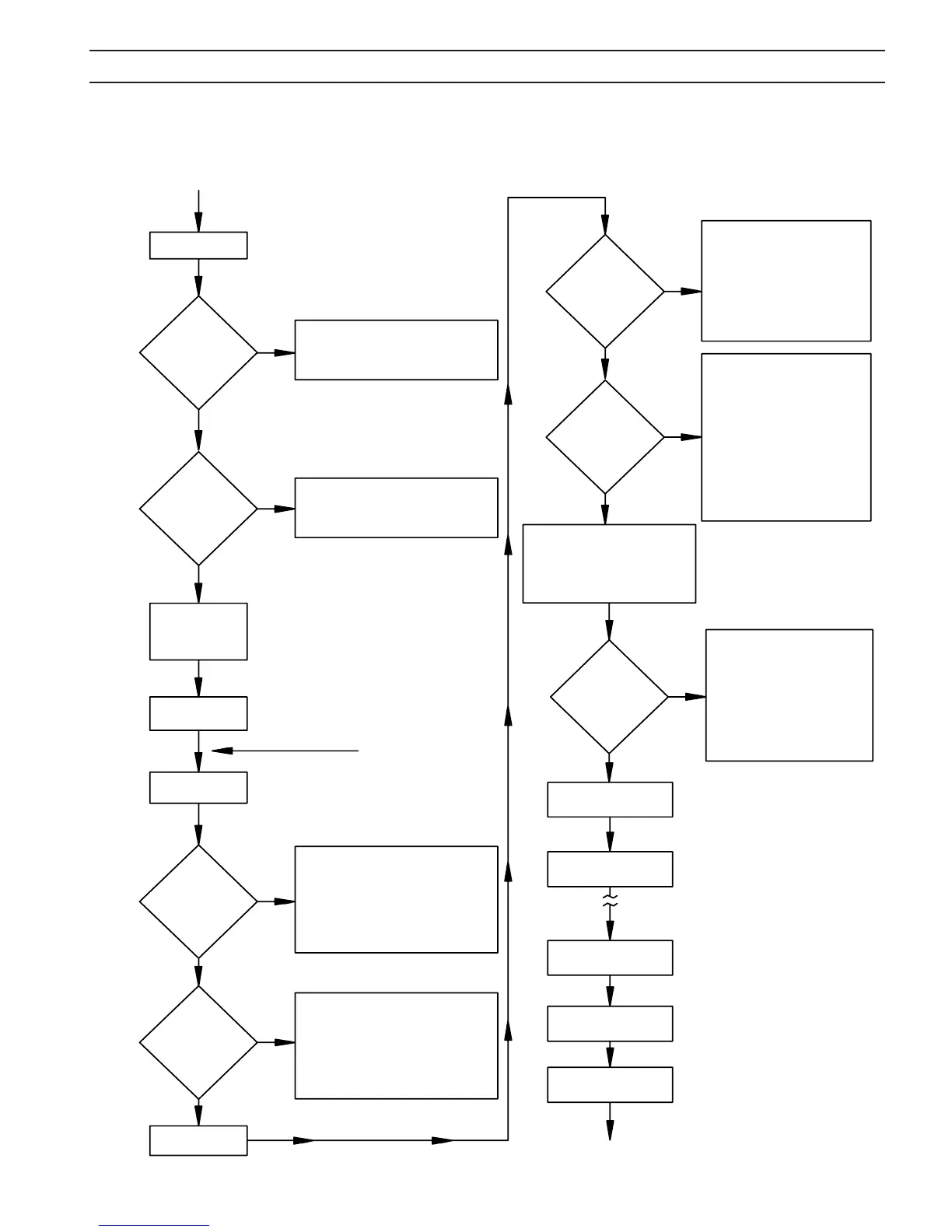

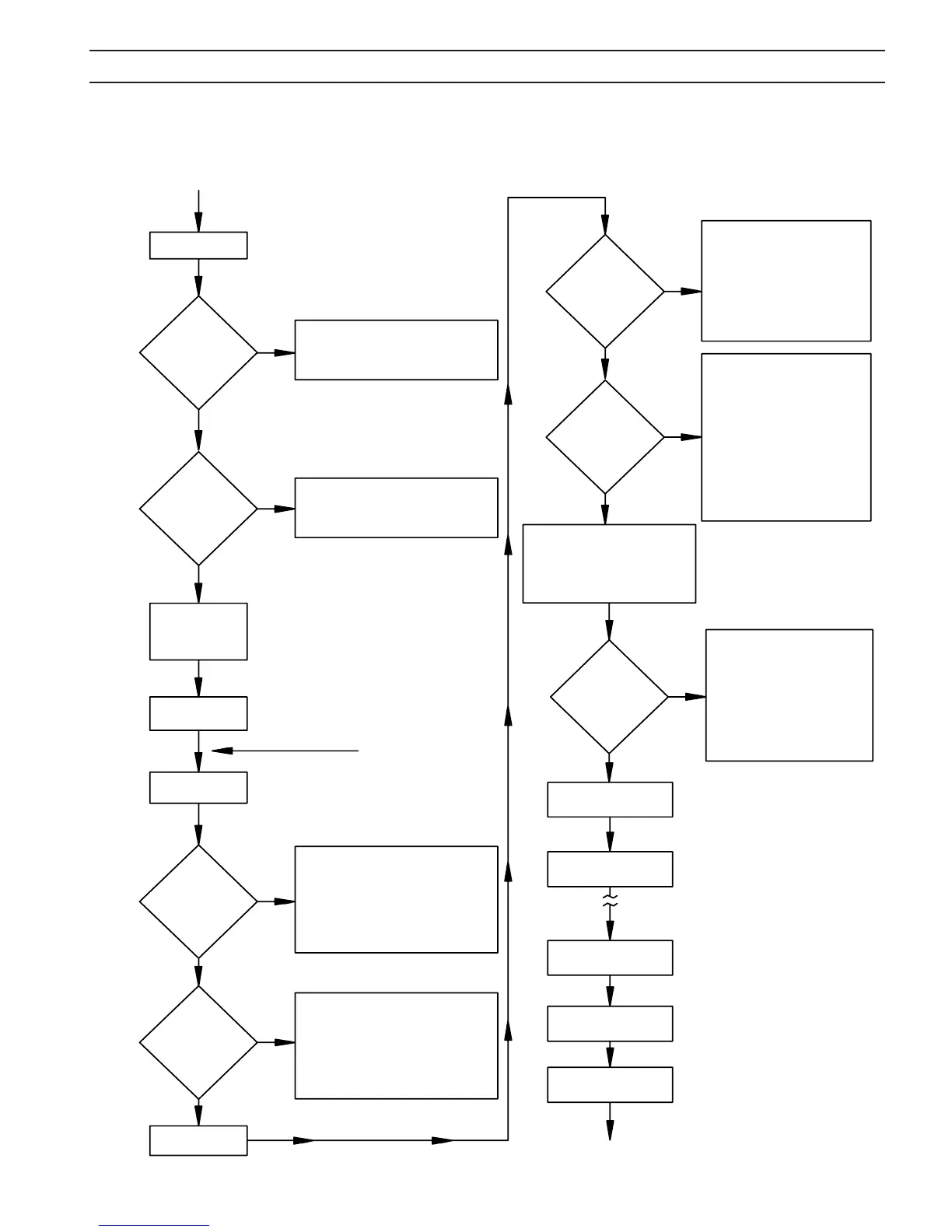

53

Proper Input

Power Applied

ROS ON

Is

OVER TEMP

Light

On?

1. Machine may be overheated.

2. Check connections to thermal switches

(TS).

Is

READY/LOW GAS

Light

On?

1. Close top lid.

2. Check ISW switch

3. Check CB1.

Set Gas(es) at proper

pressure with OSS

switch in CUT/START-

SHIELDmode.

Place OSS switch in

OPERATE

Depress Torch

Switch

Is

HIGH FREQ

Light

On?

Does

LOW GAS

Light GO

O?

1. Check input gas pressure.

2. Check gas ow of PT-26. Check to be

sure consumables are good and prop-

erly in place.

3. Check torch switch for intermittent con-

nection.

4. If using PT-26, check jumper between

pin 4 and 5.

1. Check OSS switch.

2. Check Torch Switch.

3. Check PAC contactor to insure 24 VAC is

applied to coil.

4. Check PC Board.

5. Check HFTR Transformer

2 second delay

Unit in Post Flow mode

and ready to cut again.

LOW GAS light

turns on

Release torch switch

Adjust cutting speed

HIGH FREQ light

goes out

Is

Main Arc

established

?

1. Check work lead connection.

2. Check consumables in torch.

3. Check for proper nozzle and

current. At low currents, the arc

length has to be closer to work.

4. Check all input voltages between

lines.

5. Check open circuit voltage.

6. Check diodes and SCR’s.

7. Check PC board.

Touch pilot arc to work piece within

6 sec. after pilot arc is established, or

pilot arc will turn o and begin cycling

on and o about every 3 sec.

1. Check consumables in torch.

2. Check torch connections using

ohmmeter.

3. Check open circuit voltage (325

VDC). (Disconnect HF to avoid

damaging meter.)

4. Check HF at spark gaps. (ISW

switch must be closed when

performing check.) May have to

reset spark gap.

5. Check PAC contactor.

6. Check R20 and R21 resistors.

1. Check open circuit voltage.

Should be about 370 VDC. (Dis-

connect HF to avoid damaging

meter.)

2. Check input power.

3. Check MC contactor.

4. Check diodes and SCR’s.

5. Check PC board.

Is

Pilot Arc

established

?

Does

TORCH ON

Light turn

on?

“A”

“A”

YES

NO

C. STATUS LIGHT TROUBLESHOOTING CHART

NO

YES

YES

NO

NO

YES

YES

NO

NO

YES

YES

NO

SECTION 5 MAINTENANCE

Loading...

Loading...