48

SECTION 4 OPERATION

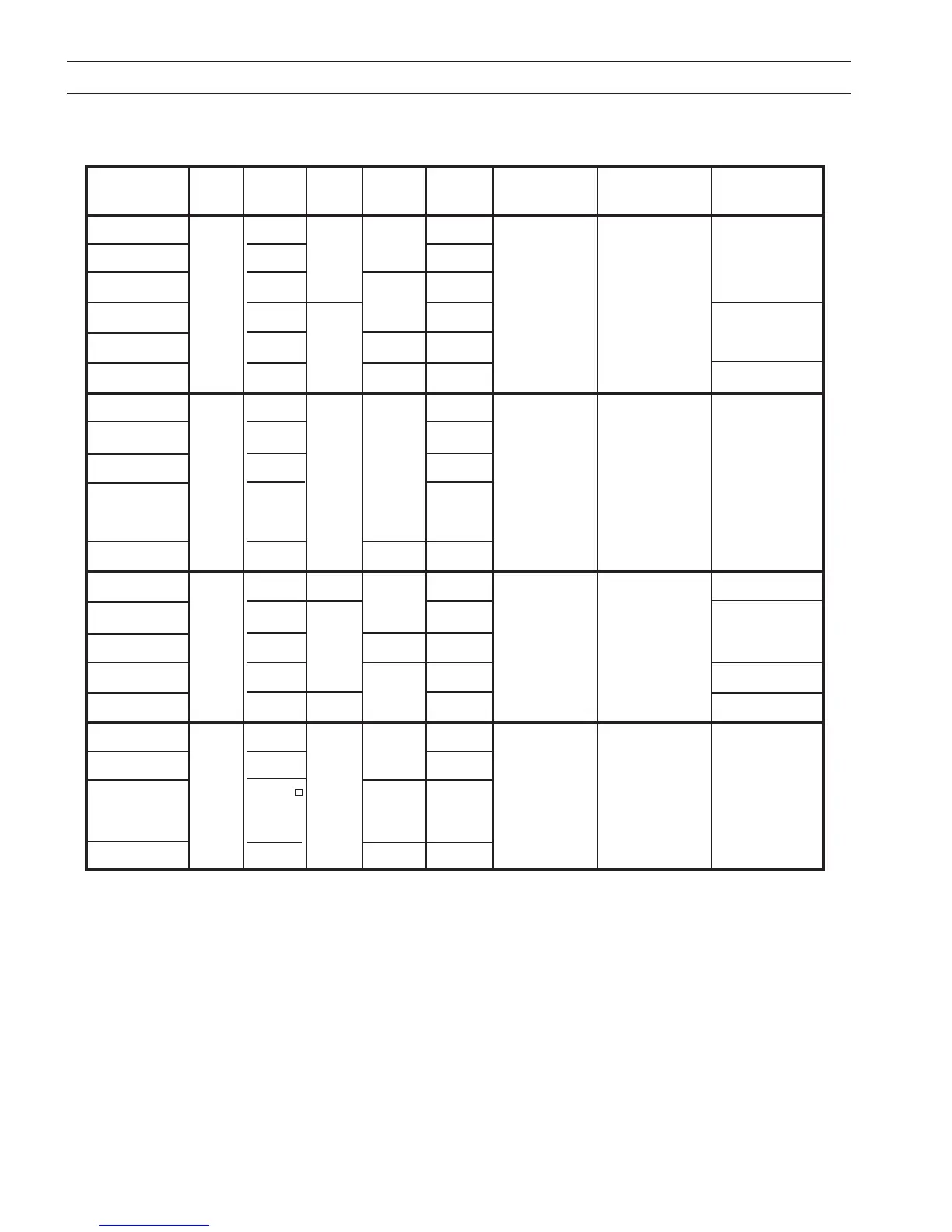

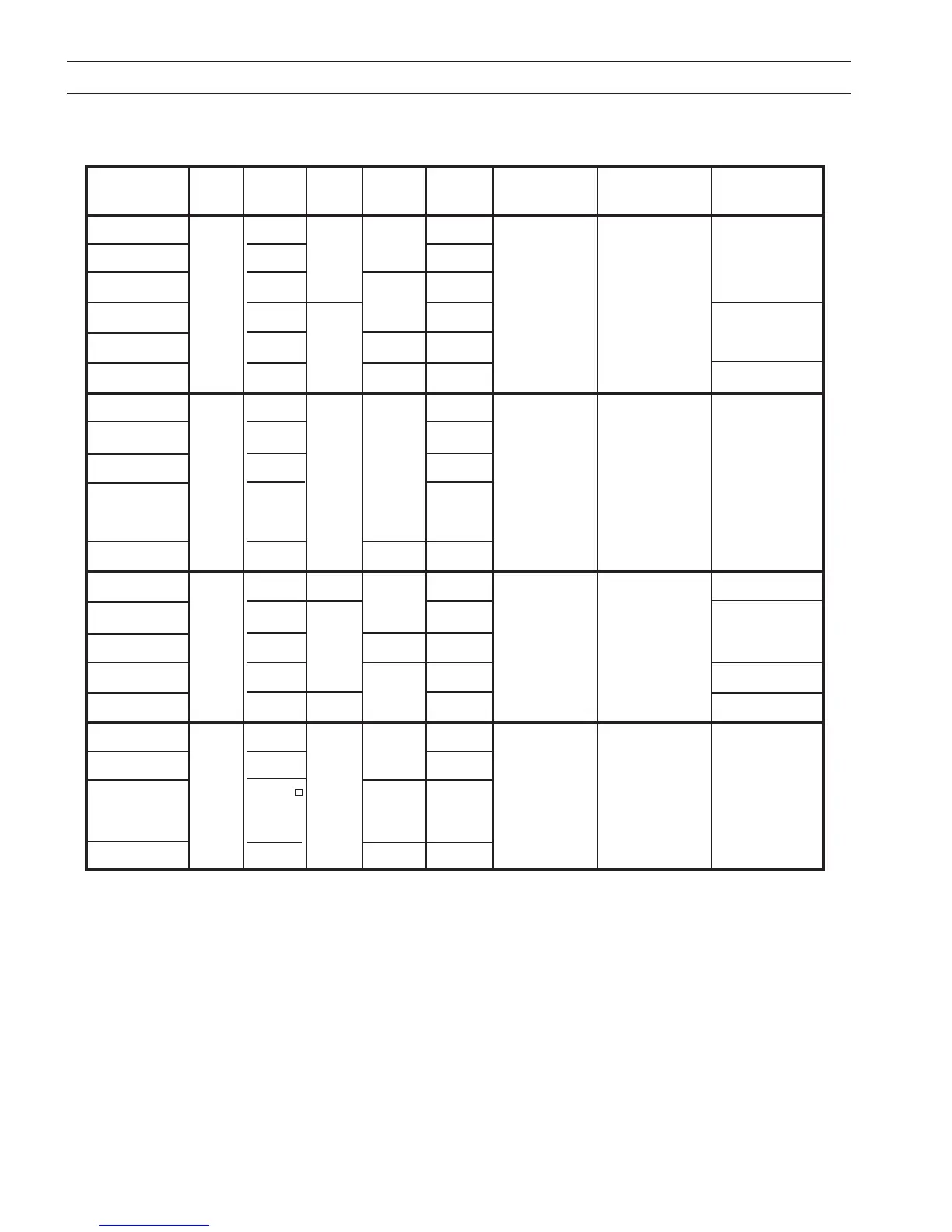

CS - 1/4 (6.4) 200 150 (3.8) 3/8 (9.6) 1/8 (3.2) 143 Air - 30 (2.07) Air - 45 (3.1) Air - 65 (4.48)

CS - 3/8 (9.6) 100 (2.54) 146

CS - 1/2 (12.7) 95 (2.4) 7/32 (5.5) 158

CS - 5/8 (15.8) 75 (1.9) 1/2 (12.7) 160 Air - 55 (3.8)

CS - 3/4 (19) 65 (1.65) 1/4 (6.4) 165

CS - 1 (25.4) 35 (.89) 3/8 (9.6) 180 Air - 65 (4.48)

CS - 1/4 (6.4) 200 170 (4.3) 3/8 99.6) 1/8 (3.2) 129 N

2

- 30 (2.07) O

2

- 45 (3.1) Air - 65 (4.48)

CS - 3/8 (9.6) 110 (2.8) 3/16 (4.8) 133

CS - 1/2 (12.7) 95 (2.4) 7/32 (5.5) 136

CS - 5/8 (15.8) 75 (1.9) 1/2 (12.7) 139 Air - 55 (3.8)

CS - 3/4 (19) 55 (1.4) 1/4 (6.4) 142

CS - 1 (25.4) 40 (1.0) 3/8 (9.6) 155 Air - 65 (4.48)

SS - 1/4 (6.4) 200 140 (3.6) 3/8 (9.6) 1/8 (3.2) 142 Air - 30 (2.07) Air - 52 (3.6) Air - 85 (5.86)

SS - 3/8 (9.6) 125 (3.2) 3/16 (4.8) 150

SS - 1/2 (12.7) 85 (2.2) 154

SS - 3/4 (19) 55 (1.4) 1/2 (12.7) 3/8 (9.6) 174

SS - 1 (25.4) 20 (.50) 180

AL - 1/4 (6.4) 200 125 (3.2) 3/8 (9.6) 3/16 (4.8) 155 Air - 30 (2.07) Air - 52 (3.6) Air - 85 (5.86)

AL - 3/8 (9.6) 110 (2.8) 1/4 (6.4) 165

AL - 1/2 (12.7) 85 (2.2) 167

Al - 3/4 (19) 60 (1.5) 1/2 (12.7) 3/8 (9.6) 182

AL -1 (25.4) 40 (1.02) 189

Current

(Amps)

Pierce

Height

in.(mm)

Cutting

Height

in.(mm)

Arc

Voltage

(Volts)

Travel

Speed

ipm(M/m)

Shield Gas

Type/Pressure

psi(bar)

Start Gas

Type/Pressure

psi(bar)

Plasma Gas

Type/Pressure

psi(bar)

Material

Type-Thickness

in.(mm)

4.4.3.5 Process Data at 200 Amps (PT-19XLS and PT-600)

NOTES: CS - Carbon Steel, SS - Stainless Steel, AL - Aluminum

All N

2

Plasma/Air Shield, 200 Amp cuts on Aluminum and Stainless Steel have fair surfaces except 1” (25.4mm) AL that is poor.

Pilot Arc -- HIGH

Loading...

Loading...