P18/54 T-SM47j

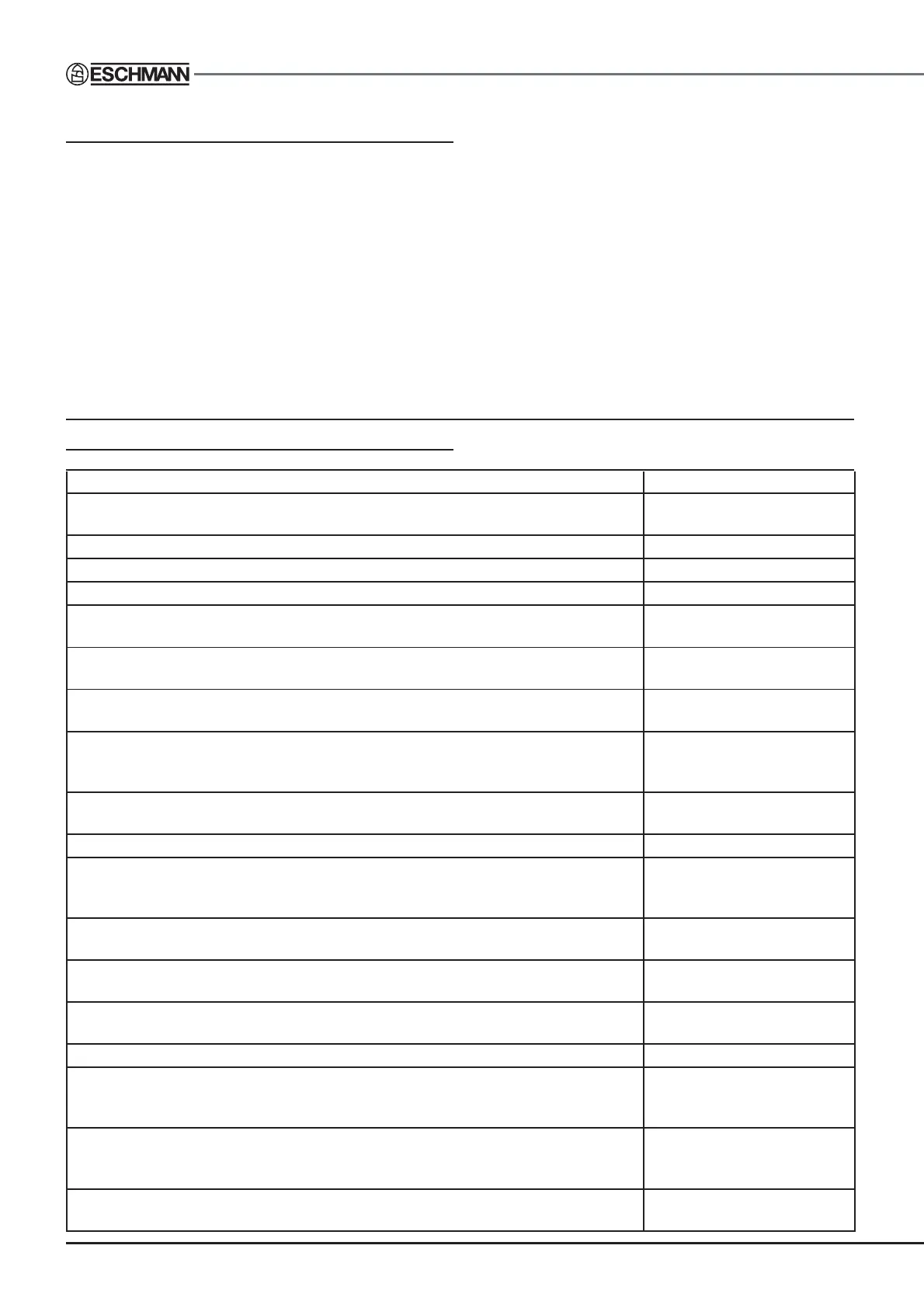

5.4 Service schedule and safety check

4. Prior to changing a motor check it has failed and that

the fault is not in the control electronics (6.6.6 - 6.6.9).

5. In the sections below where the word ‘check’ is used

it is inferred that if the check reveals a fault then this

should be corrected.

6. Tilt tabletop into service position as required (1.9) but

note safety warning, section 4.1.

7. The right-hand column should be used to tick off each

item of the schedule on completion and to note parts

replaced (or wearing that will soon need replacing).

8. This schedule should be photocopied and completed,

copies to be retained by the engineer conducting the

service and the person responsible for the table.

This should be performed every 6 months to ensure the

continued safe operation of the table.

NOTES:

1. The numbers in brackets in this schedule details the

section of this manual that should be referred to when

performing or checking the activity detailed.

2. Prior to service operate all table functions (6.7) to

ensure correct operation, note any problems for

investigation during the service.

3. Remove base covers as required (6.2.2.1). Access

can be gained to the lower, lower-mid, upper-mid and

top of the column (6.2.3.2 to 6.2.3.5). If necessary the

telescopic covers can be removed (6.2.4.1).

1. Check pedal dampers for wear or leaking (6.3.3).

2. Disassemble, clean and lubricate the two fixed wheel assemblies and the four

castor assemblies (6.3.4, 6.3.5). Test resistor assembly as 6.3.5.1 (viii).

3. Check brake pads for wear, damage, or hard and brittle (6.3.6).

4. Check the castor pillar and pedal spindle bushes for wear (6.3.7 and 6.3.8).

5. Check and lubricate both lifting roller assemblies (6.3.9).

6. Check for wear of both pedal catch mechanisms (6.3.12) and renew the anti-

slip pad on both pedals (6.3.11).

7. Check security of all fixing screws, nuts and retaining clips within the base area

and check the pedal operation works smoothly and correctly.

8. Check main and standby battery voltage (standby and load) as 6.3.2.(iia). Check

security, connectors and loom routing of PSU.

9. Check the Trendelenburg, tilt and telescopic column actuator assemblies for

excessive wear or failure (6.4.2, 6.4.3, 6.4.4 and 6.4.5) and grease worm and

wheel on Trendelenburg and tilt motor assemblies.

10. Check the security and positioning of all wiring looms and connections. Add

cable ties, reposition or replace as necessary.

11. Check switch and fuse panels for operation and signs of damage (6.6.16).

12. Check for wear or damage to the tilt and Trendelenburg bushes in the trend

and tilt frame (6.4.6 and 6.4.7). Check all fixing screws within the inner and

outer (tilt and Trend) gimbal assemblies.

13. Check the wraparound aligning bearing pads, adjust as required to remove play

or replace (6.4.8).

14. Check height potentiometer is secure to the wrapround and that the cable is in

good condition and secure to the base (6.6.13).

15. Check the security and the routing of the 4 actuator PCA, connectors, energy

chains and all looms within the column. Cable-tie if necessary

16. Remove and replace bellows if split/damaged (6.2.5).

17. Check the security and the routing of the Three actuator PCA, connectors,

energy chains and traverse and break motor looms within the traverse housing.

Cable-tie if necessary.

18. Check that traverse motor and traverse belt tensioners are secure to the support

plate and lubricate tensioner bearings between screw and bearing only. Check

traverse motor (6.5.2.1) and adjustment of the traverse belt tensioners’ (6.5.2.2).

19. Check the condition and lubricate if necessary the drive belt guide needle

bearings between screw and bearing only (6.5.2.9).

Base and column:

Loading...

Loading...