T-SM47j P39/54

T20-a

OPERATION TABLE

vii Continue to reassemble the table by reversing the

above (use threadlock part number 670650 on screw

threads and note any applicable torque values

shown on Fig. 6.5 and 6.6). Ensure all electrical

connections are remade and all looms are secured

as found and carry out a full function test.

6.5.2.5 Side rails

To replace a long or short trunk side rail proceed as follows,

traversing the table (fully cranially) as required to gain

access to the fixing screws:

i Remove the screws securing the side rail from

beneath the table top on the inside edge of the side

arms (items 15 and 17 of Fig. 6.6 and items 10 and

16 of Fig. 6.5). Note that on the long trunk section

there is a central short screw that can be released

through the hole on the inside of the side arm.

ii Secure the new side rail to the section (use

threadlock part number 670650 on screw threads

and note torque value of 21Nm).

6.5.2.6 Top covers

To remove or replace a long or short trunk top cover

proceed as follows, traversing the table as required to gain

access to the fixing screws:

i Remove the side rails as detailed in section 6.5.2.5

and then the small screws securing the lower edge

of the cover to the side arms.

ii Remove the screw cover on the mattress retaining

screws and then remove the mattress retainers.

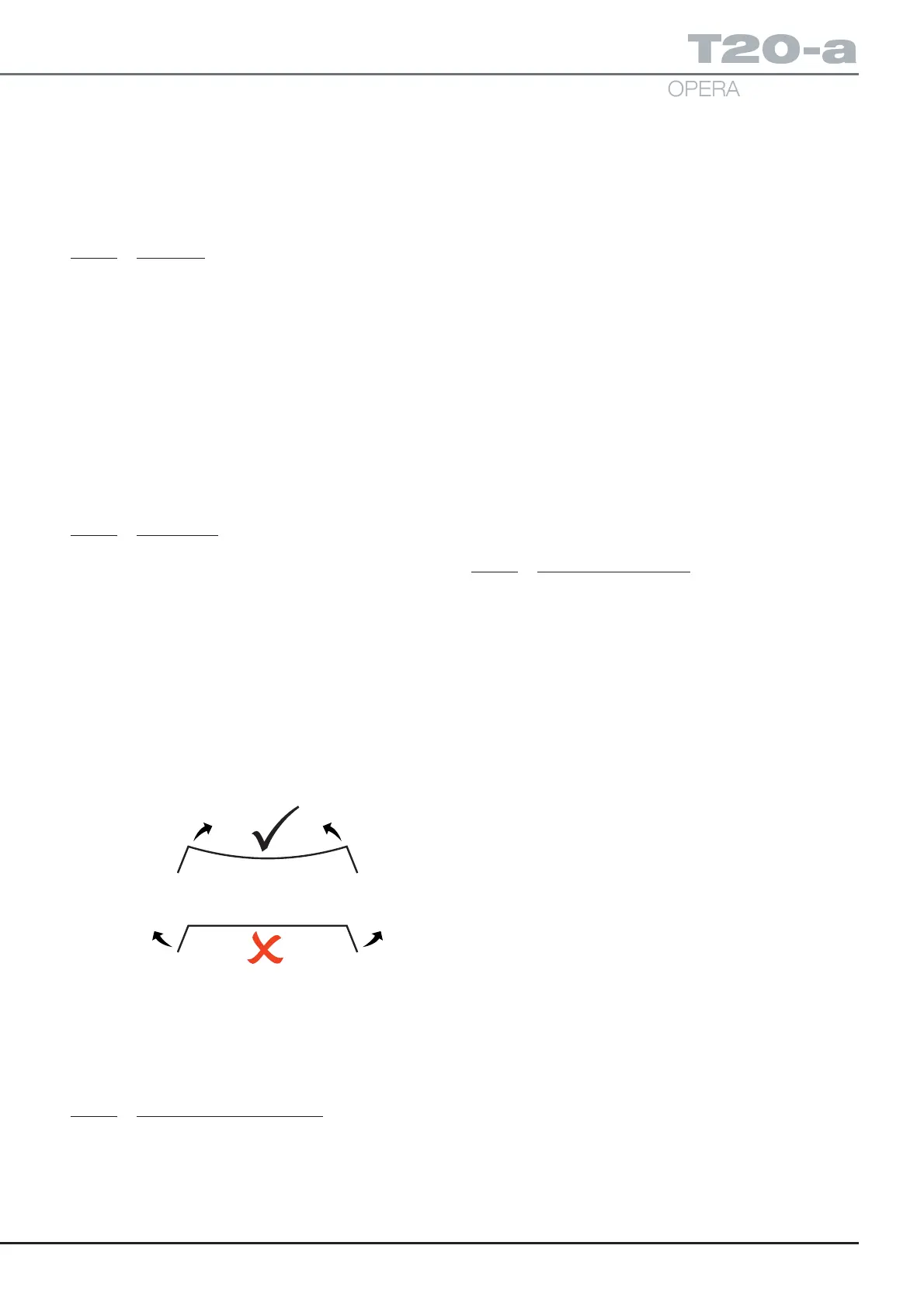

Carefully release the lower edge of the cover on

each side and flex the cover from the middle to

release it, not by bending out the sides, see diagram

below. Take care not to damage it if it is to be reused

and not replaced.

iii To replace the cover reverse the above using

threadlock part number 670650 on all screw threads

(except the small M3 Torx screws retaining the lower

edge of the cover, note torque setting of 0.5Nm for

these) and note any other applicable torque values

shown in Fig. 6.5 and 6.6.

6.5.2.7 Push button components

The push button assembly (locking or non-locking) does not

require any special adjustment after assembly. Should any

part require replacement or cleaning follow the method below

to take the assembly apart and reassemble it, replacing parts

as required during the procedure. On the short trunk it will

be necessary to remove the ‘P’ clip on the break gearbox

loom and the bottom cover (item 3 and 11 of Fig. 6.6).

i Remove the ‘R’ clip in the end of the push button

from below the table top. This will release all the

push button components (locking or non-locking).

ii Slide out the push button with its return spring and for

the locking push button push the plunger (i.e. item 4 of

Fig. 6.5) out the back of the attachment block which

will eject the ball bearing and compression spring.

iii Clean or replace components as required, clean out

any debris from recess and reassemble without

lubrication. Ensure that on assembly the slot in the

top of the push button blade is correctly positioned

over the roll pin in the attachment block.

iv Reassemble the table (use threadlock part number

670650 on screw threads and note any applicable

torque values shown in Fig. 6.5 and 6.6 ) replacing

the ‘P’ clip and the bottom cover if removed and

check button function by attaching and removing a

suitable table section several times.

6.5.2.8 Traverse rod bearing

To replace the traverse rod bearings item 3 of Fig. 6.7

(always replace as a set of four) proceed as follows:

i Remove the long trunk section cover as 6.5.2.6.

ii Remove the short trunk bottom covers (items 3 and

11 of Fig. 6.6) and release connections from the

break potentiometer loom and connections from the

break motor where they join the break motor loom .

iii Remove the four M8 countersunk screws securing

the short trunk in place (two either side) and remove

the short trunk by sliding the gearbox arms out of

the long trunk.

iv Remove the set screws securing the end of the lead

screws (items 13 of Fig. 6.5) and remove the black

top (items 17 of Fig. 6.5) from the long trunk section.

v Remove the black top location dowels from the break

attachment blocks (items 11 and 14 of Fig. 6.5) and

all the button head screws.

vi Whilst supporting each side arm in turn withdraw

the break attachment blocks.

vii Slide out the traverse rods and knock out the

traverse rod bearings.

viii Carefully replace the new set of bearings and

reassemble the table by reversing the above (use

threadlock part number 670650 on screw threads,

see note on Fig.6.6 and note any applicable torque

values shown in Fig. 6.5, 6.6 and 6.7 (e.g. lead screw

set screw 20Nm black top screws 6Nm). Ensure all

electrical connections have been made.

ix Test all table functions.

Loading...

Loading...