T-SM47j P33/54

T20-a

OPERATION TABLE

6.5 TABLE SECTIONS

This section is split into two parts as follows:

6.5.1 Head and leg section (see Fig. 6.4).

6.5.2 Trunk sections, long and short (see Figs. 6.5 to 6.7).

6.5.1 Head and leg section

The following parts may need replacement in the event of

wear or damage (see notes below in each section) and

the procedures for these are detailed below:

6.5.1.1 Guide pins

6.5.1.2 Gas springs

6.5.1.3 Cover

6.5.1.4 Gas spring release head / pivot pin

6.5.1.5 Gas spring release handle

6.5.1.6 X-ray translucent top

See Fig. 6.4 for the general arrangement of the head and

leg section assembly, the figure shows the leg section, but

note that the head section is similar (no cross bar or middle

side bar screws).

6.5.1.1 Guide pins

To replace a guide pin if worn or damaged remove the

retaining screw and refit a new pin. Apply threadlock to the

screw (part number 670650) and lubricate the pin sparingly

with grease (part number 110477). Tighten securing screw

to a torque setting of 8Nm. Check section fits table correctly.

6.5.1.2 Gas springs

WARNING

Gas springs are filled with high-pressure gas.

DO NOT attempt to open them, see section

6.5.1.2 (vii) before disposal.

CAUTION

Gas springs do not require

additional lubrication.

To replace a gas spring if it shows sign of oil leakage or

has become spongy (pressure applied on one side of the

section produces noticeably more movement than the

other) proceed as follows:

i Remove section from table and rest it on a suitable

work surface upside down.

ii Remove the shoulder screw in the mounting block

at the cylinder end.

iii Release locking nut at the end of the piston and

unscrew gas spring piston from release head casting.

iv Wind nut on the new gas spring well down thread,

lubricate actuating nipple with grease (part number

110477). Screw gas spring into the release head

casting until play has been removed between the

release handle actuator and the gas spring release

button, then back off approximately half a turn. Apply

threadlock (part number 670650) and tighten the

piston-locking nut onto the release head casting.

v Apply grease (part number 110477) to the shank

and threadlock (part number 670650) to the thread

of the shoulder screw and replace it into the

mounting block, tighten to a torque setting of 10Nm.

vi Actuate the release lever to align the guide pins and

replace section into a table trunk section. Check that

the section works correctly and that both gas springs

are working together, adjust if required as ‘iv’ above

and remove any excess threadlock.

vii. Before disposing of the gas spring it is suggested

that the high pressure gas is released from within

the cylinder to avoid the possibility of injury (or return

it to Eschmann Equipment). To release the gas

(nitrogen and a small amount of hydraulic oil) locate

the gas spring positively onto the bed of a drilling

machine taking care not to puncture the cylinder.

Do not centre punch to provide a drill guide as this

may rupture the cylinder and wear suitable eye and

hand protection. Use a 2-3mm diameter drill at slow

speed and drill a hole 25-30mm from the mounting

end of the cylinder to a depth of half the cylinder

diameter to vent the gas. Clean up any oil spillage.

6.5.1.3 Top cover

To replace a top cover if damaged proceed as follows:

i Remove section from table and rest it on a suitable

work surface upside down.

ii Remove the four M8 screws (six on the leg section)

that secure the sidebars.

iii Turn section over and remove the mattress retainers.

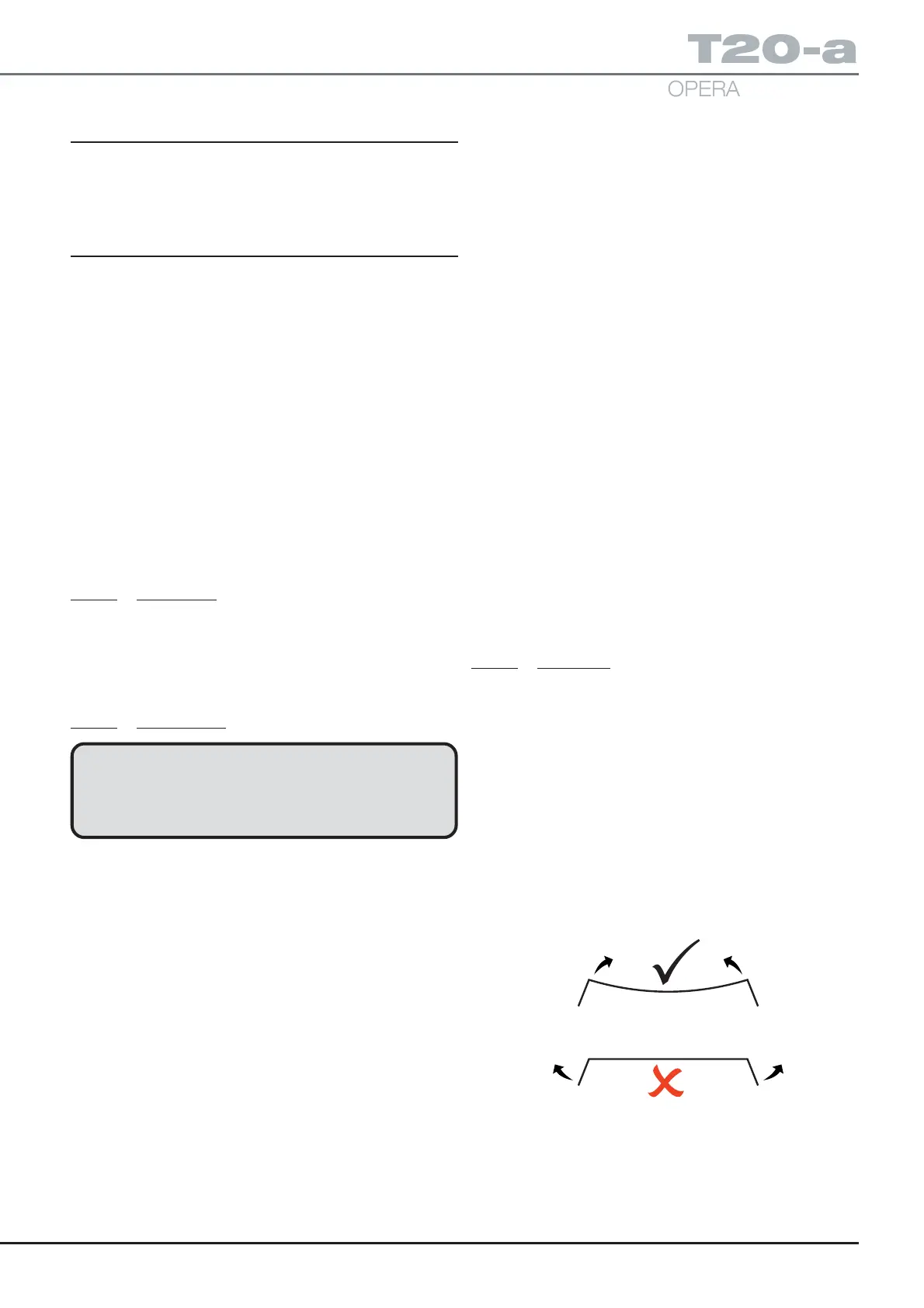

iv Carefully release the lower edge of the cover on

each side and flex the cover from the middle, do not

bend out the sides, see diagram. Replace cover with

the new one and replace the mattress retainers

using threadlock (part number 670650) on the screw

threads.

v Replace the sidebars and secure using threadlock

(part number 670650) on the screw threads and

tighten to a torque setting of 15Nm. Finally check

section function.

Loading...

Loading...