30 www.eta.co.at

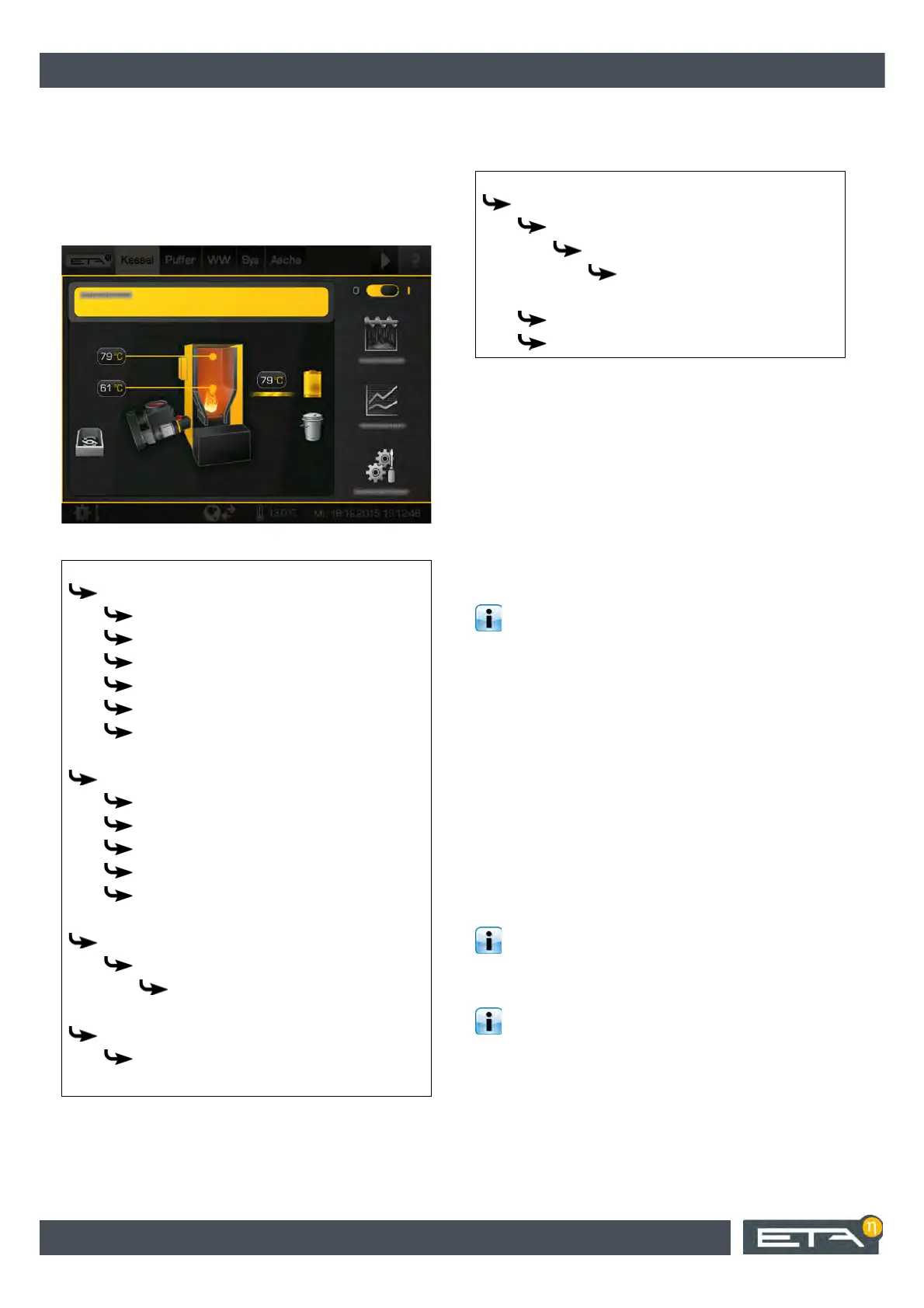

[Boiler] function block – HACK Configuration parameter

6 Configuration parameter

6.1 [Boiler] function block – HACK

Parameters to be set

Set or check the following parameters.

Detailed descriptions of the parameters are provided

below.

Explanation of [Fuel]

This parameter sets the type of fuel used. The control

system contains appropriate values for each type of

fuel, to ensure optimum combustion and de-ashing.

Explanation of [Water content]

This parameter is used to set the current fuel's water

content for optimum regulation of combustion.

Water content = weight of water divided by total

weight (wood + water).

Explanation of [Fuel density [kg/m³]]

This parameter is used to set the current fuel's density

for optimum regulation of combustion.

Factory settings:

• Wood chips: 250 kg/m³

• Pellets: 650 kg/m³

• Miscanthus: 110 kg/m³

Explanation of [Flue gas recirculation]

When the fuel setting is changed in the control system,

the status of the flue gas recirculation is adjusted auto-

matically.

If the fuel is set to [Pellets] or [Miscanthus], the

setting for flue gas recirculation is changed to

[Yes].

If the fuel is [Woodchips], the setting is [No].

However, if wood chips with less than 15% water

content are used, the [Yes] setting must be made

manually.

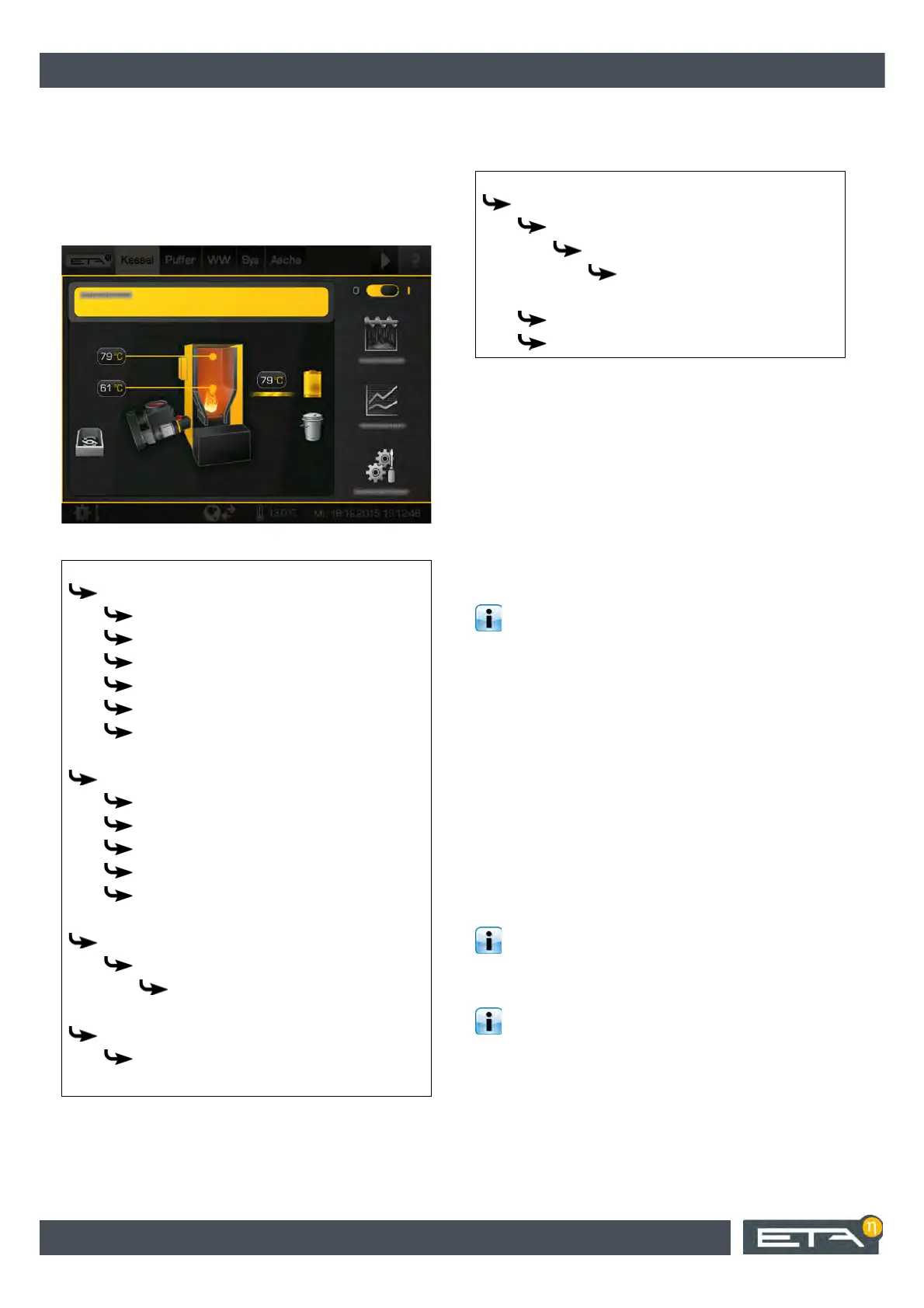

Boiler

Settings

Fuel

Water content

Fuel density [kg/m³]

Flue gas recirculation

Conveyor type

Lock aux. boiler

Ash removal

De-ash after min.

De-ash after max.

Begin idle time WT cleaning

Idle time during WT cleaning

Empty ash box after

Return

Return riser valve

MixValve runtime

Residual O2

Increase O2 target value

Conveying system

Stoker unit

Stoker

Conv. time

Start lag

Stoker delay

Relation of runtime

Loading...

Loading...