7. Mounting

NOTICE

Device damage due to improper installation or unsuitable ambient conditions.

Ì Read heads and actuators must not be used as a mechanical end stop.

Ì Observe EN ISO 14119:2013, sections 5.2 and 5.3, for information about fastening the safety

switch and the actuator.

Ì Observe EN ISO 14119:2013, section 7, for information about reducing the possibilities for by-

passing an interlocking device.

Ì The evaluation unit must be mounted in a control cabinet with a minimum degree of protection of

IP54. A snap-in element on the rear of the device is used for fastening to a mounting rail.

Ì If several evaluation units are mounted side by side in a control cabinet without air circulation (e.g.

fan), a minimum distance of 10mm must be maintained between the evaluation units. This dis-

tance enables the heat from the evaluation unit to dissipate.

Important!

Ì From the assured switch-off distance S

ar

, the safety outputs are safely shut down.

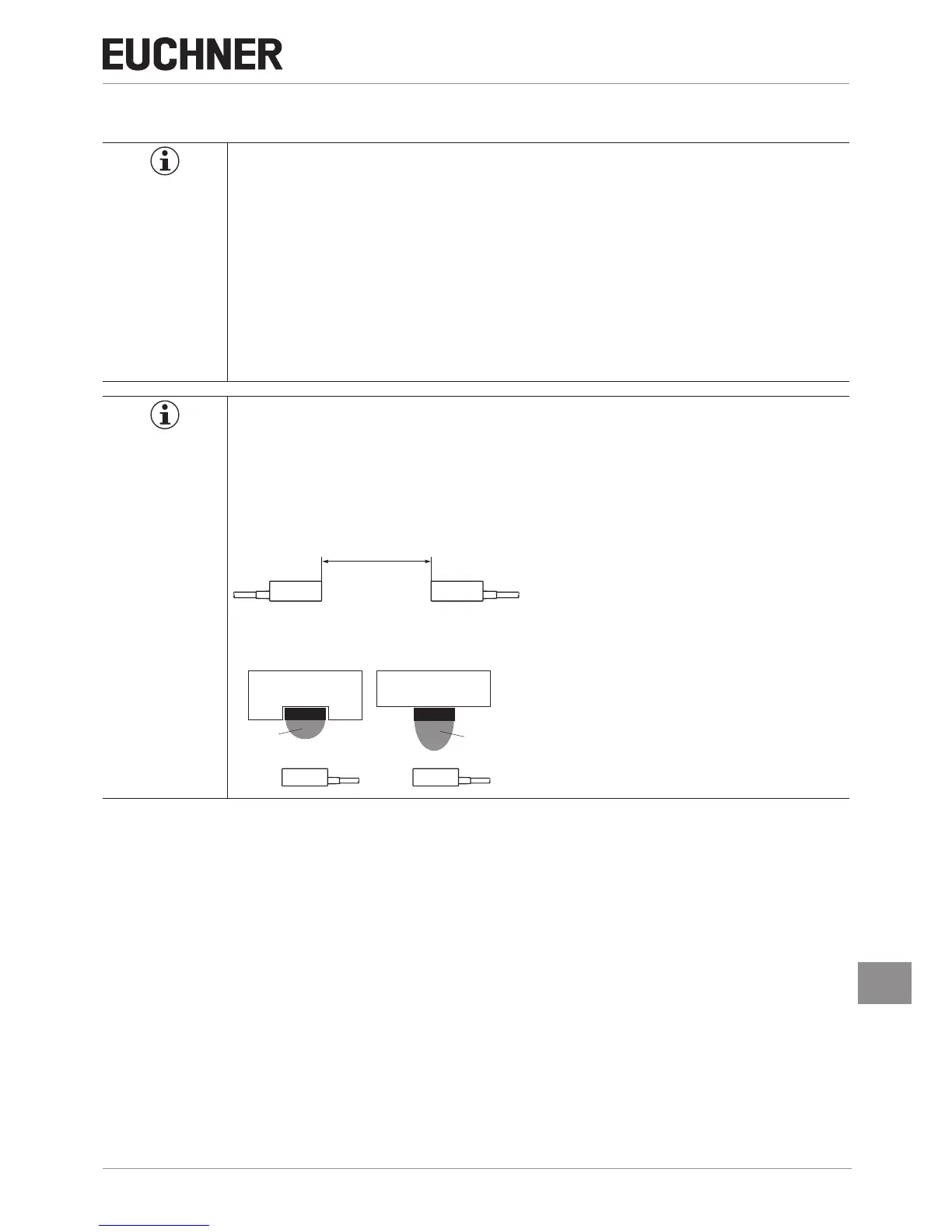

Ì When mounting several read heads, observe the stipulated minimum distance to avoid mutual in-

terference.

- For CES-A-LNA/-LCA s

min

=50mm

- For CES-A-LMN s

min

=20mm

- For CES-A-LQA s

min

=80mm

s

min

Ì If the actuator is installed ush, the switching distance changes as a function of the installation

depth and the safety guard material.

Operating

distance

Actuator

Operating

distance

Actuator

Flush mounting Surface mounting

Note the following points:

Ì Actuator and read head must be tted so that

- the front faces are at the minimum switch-on distance 0.8xS

ao

or closer when the safety guard is closed (see section

Operating distances). To avoid entering the area of possible side lobes, a minimum distance is to be maintained in

case of a side approach direction. See section Typical operating distance for the related actuator.

- a hazard is excluded until the assured switch-off distance (S

ar

) is reached when the safety guard is open.

- the actuator is positively mounted on the safety guard, e.g. by using the safety screws included.

- they cannot be removed or tampered with using simple means.

Ì Pay attention to the maximum tightening torque for the read head or safety switch and actuator mountings of 1Nm. For

read heads/actuators made of PE-HD, the maximum tightening torque is only 0.5Nm.

Loading...

Loading...