113

ELECTRICAL AND IGNITION

TIMING ADJUSTMENTS

6

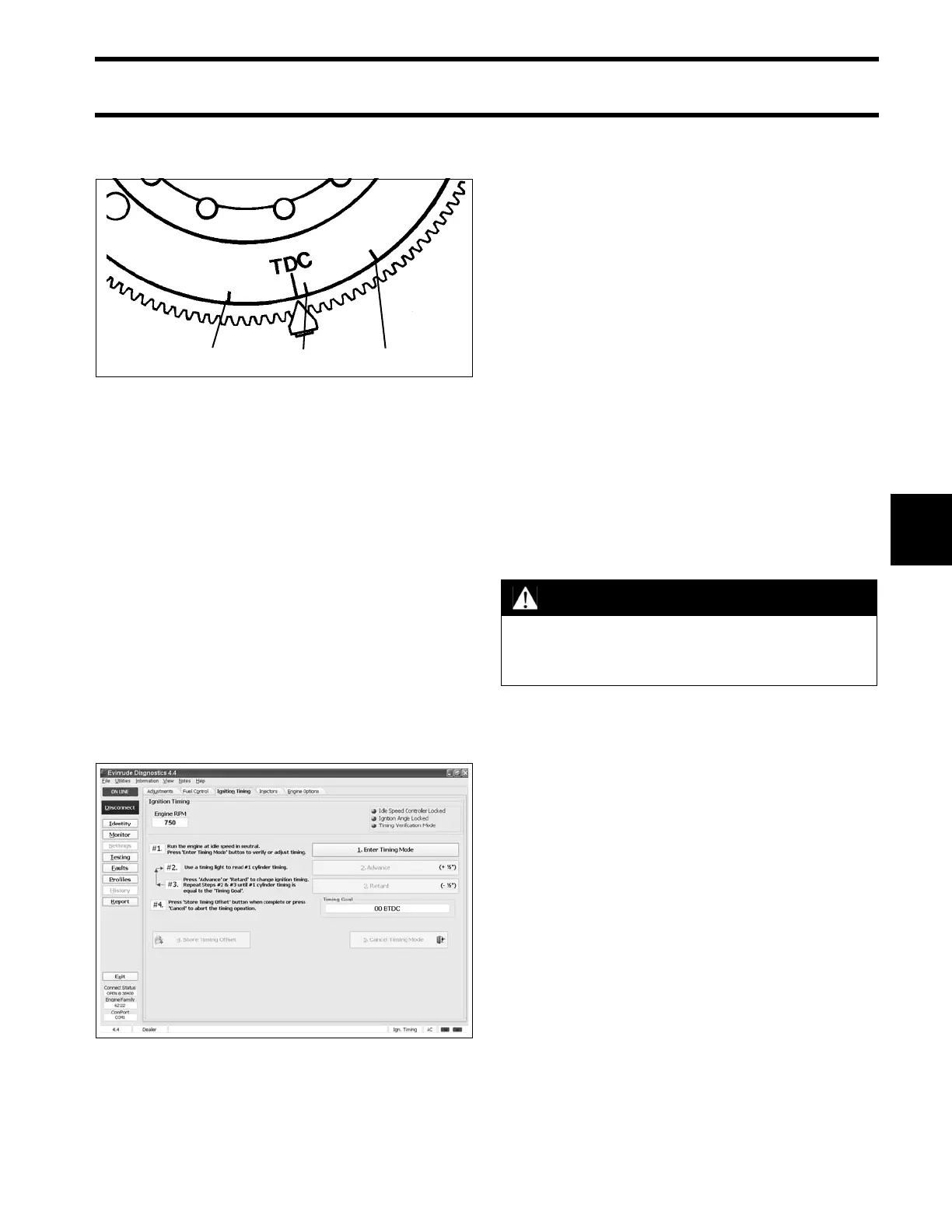

location to align with the cast-in TDC boss on the

flywheel. Tighten retaining screw.

Repeat the entire adjustment process to make

sure pointer is aligned correctly.

Install spark plugs. Refer to Spark Plug Indexing

on p. 40.

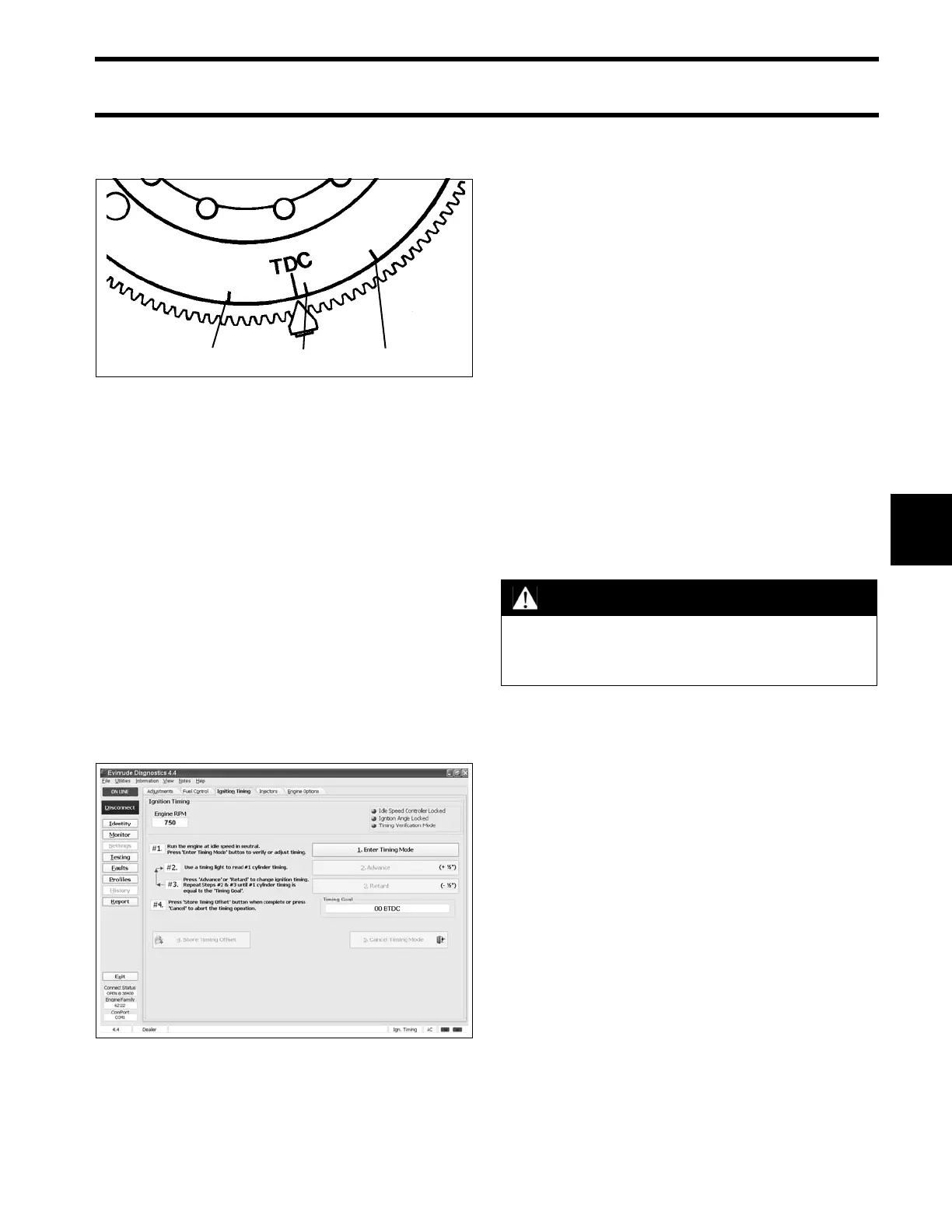

Timing Verification

Use Evinrude Diagnostics software to synchronize

the mechanical timing of the outboard with the

electronic timing of the EMM.

Start the outboard.

Use the Settings/Ignition Timing screen of the

diagnostics software and follow the on-screen

instructions.

Check ignition timing after any of the following

procedures:

• Powerhead replacement

• Crankshaft replacement

• Flywheel removal or replacement

• CPS replacement

• EMM replacement

• EMM software replacement (reprogramming)

IMPORTANT: Make sure the timing pointer is

set and the outboard reaches operating tempera-

ture before making any timing adjustments.

TPS CALIBRATION

Use Evinrude Diagnostics software to tell the

EMM what throttle position sensor voltage is when

the throttle plates begin to open.

Set TPS Calibration after replacing or adjusting

any throttle body or throttle linkage parts.

Remove the air silencer.

Turn the key switch to the ON position. Do NOT

start the outboard.

MODELS WITH ICON ELECTRONIC SHIFT AND

THROTTLE

Rotate the propeller shaft and use the ICON

remote control to shift the outboard into FOR-

WARD gear. Rotate the propeller shaft to confirm

the outboard is in FORWARD gear.

Fully advance the throttle. The throttle actuator

should move the throttle plates to the wide open

throttle position.

1. Mark “A’”

2. Mark “B”

3. Mark “C”

DR1233

Timing Adjustment Screen 008110

WARNING

To prevent accidental starting of outboard,

disconnect crankshaft position sensor

(CPS).

Loading...

Loading...