14

www.evolutionpowertools.com

(7.4)

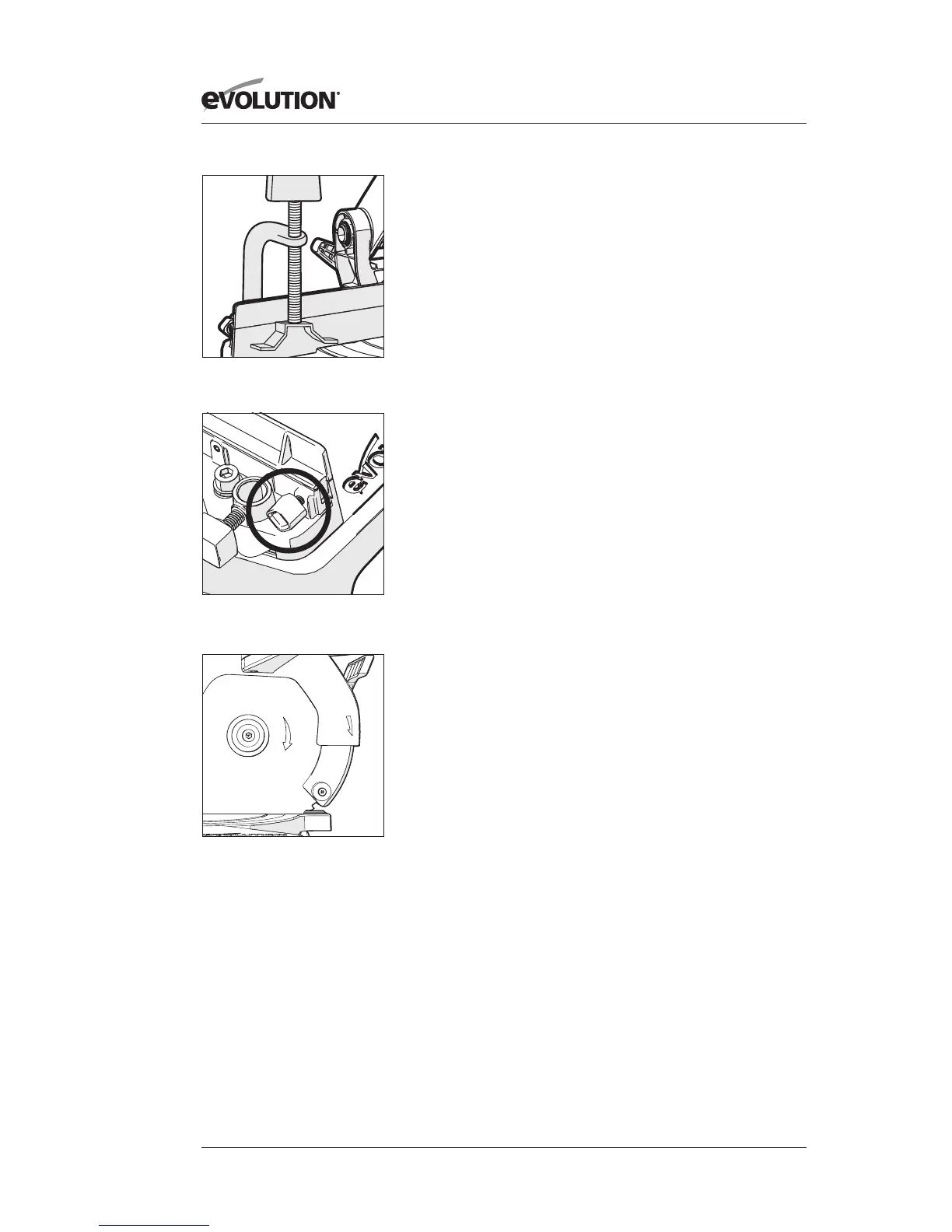

HOLD DOWN CLAMP (Fig. 4)

Two sockets (one either side) are incorporated into the rear

of the machines fence. These sockets are for positioning the

top hold down clamp.

• Fittheclamptotheretainingsocketthatbestsuitsthe

cutting application, ensuring that it is fully pushed down.

• Placetheworkpiecetobecutontothesawrotarytable,

against the fence and in the desired position.

• Adjusttheclampusinghand-wheelsothatitsecurelyholds

the workpiece to the saw table.

Conduct a ‘dry run’ with the power disconnected. Ensure that

the top hold down clamp does not interfere with the path of

the blade, or with the path of any other part of the cutting

head as it is lowered.

THE SLIDING UPPER FENCE SECTION

Note: The left hand side of the fence has an adjustable upper

section. When some acute mitre or bevel angles are selected

it may be necessary to slide the upper portion of the fence to

the left. This should normally create the clearance necessary to

allow the cutting head and blade to be lowered without

them fouling any other parts of the machine.

To adjust the fence:

• Loosenthethumbscrew(Fig. 5).

• Slidetheuppersectionofthefencelefttotherequired

position and tighten the thumbscrew.

• Conducta‘dryrun’withthemachinedisconnectedfrom

the power supply to conrm that there is no interference

between machine parts as the cutting head is lowered.

(8.1)

OPERATING INSTRUCTIONS

Caution: The mitre saw should be inspected (particularly for

the correct functioning of the safety guards) before each use.

Do not connect the saw to the power supply until a safety

inspection has been carried out.

Ensure that the operator is adequately trained in the use,

adjustment and maintenance of the machine, before

connecting to the power supply and operating the saw.

(8.2)

WARNING: To reduce the risk of injury, always unplug the

saw before changing or adjusting any of the machines parts.

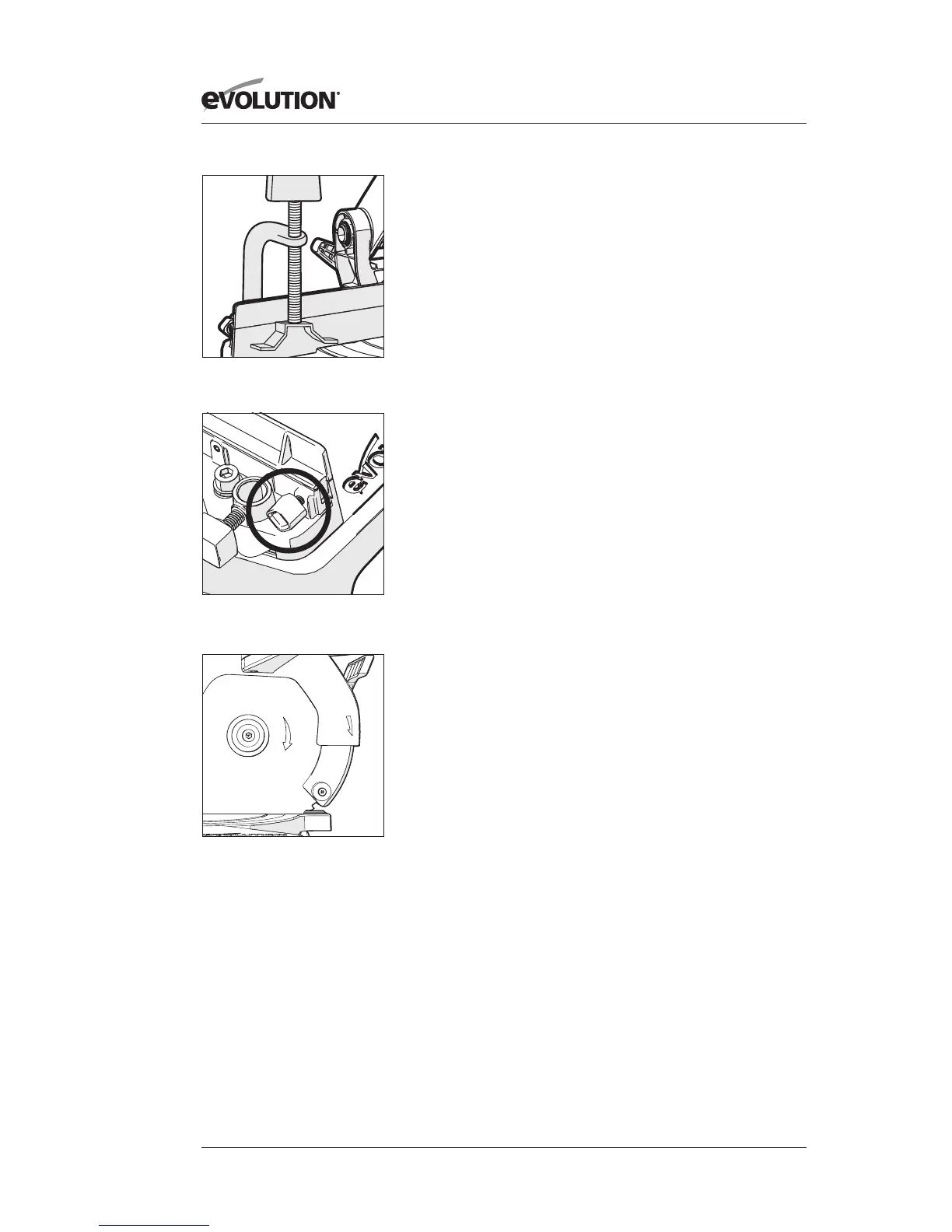

Compare the direction of the rotation arrow on the guard

to the direction arrow on the blade. The blade teeth should

always point downward at the front of the saw (Fig.6). Check

the tightness of the arbor screw.

Fig. 4

Fig. 5

Fig. 6

A B

Loading...

Loading...