16

www.evolutionpowertools.com

Some further minor assembly is required to commission this

machine.

WARNING: This machine is heavy. Enlist competent help when

removing this machine from its packaging.

DEPLOYING THE LEGS

The legs are stored underneath the machines main body.

• Releasetheretaininglatch(Fig 13).

• Deploythelegs.

• Ensurethatthelegsaresecuredintotheirserviceposition.

• Thelatchmustdeployandlockthelegssecurelyintheir

service position.

Note: This machine is heavy. Competent help should be

enlisted when moving this machine. Competent help may also

be required when deploying the leg assembly and/or storing

the leg assembly underneath the machine.

THE RIVING KNIFE

The Riving Knife is a very important component, and must be

tted correctly.

The Riving Knife has two functions:

• Itpreventsthework-piecefrombindingasitpassesthrough

the blade.

• Itprovidesasuitableconnectionpointforthebladeguard.

To t and/or check the Riving Knife:

WARNING: Ensure that this procedure is only carried out with

the machine disconnected from the mains supply.

• RemovetheTableAccessPlatebyturningthexingscrew

¼ of a turn. Lift the Access Plate from the machine (Fig. 14).

Carefully store this component for later use.

• Raisethebladetoitshighestposition-Seepage19

‘RAISING/LOWERING THE BLADE’ section.

• LoosentheRivingKnifexingboltbyseveralturnsandraise

it to its highest point (Fig. 15).

• SlidetheRivingKnife(itisslottedforconvenience)between

the xing plate and mounting block (Fig. 15). Ensure that the

mounting blocks projecting lugs engage with the slot in the

Riving Knife.

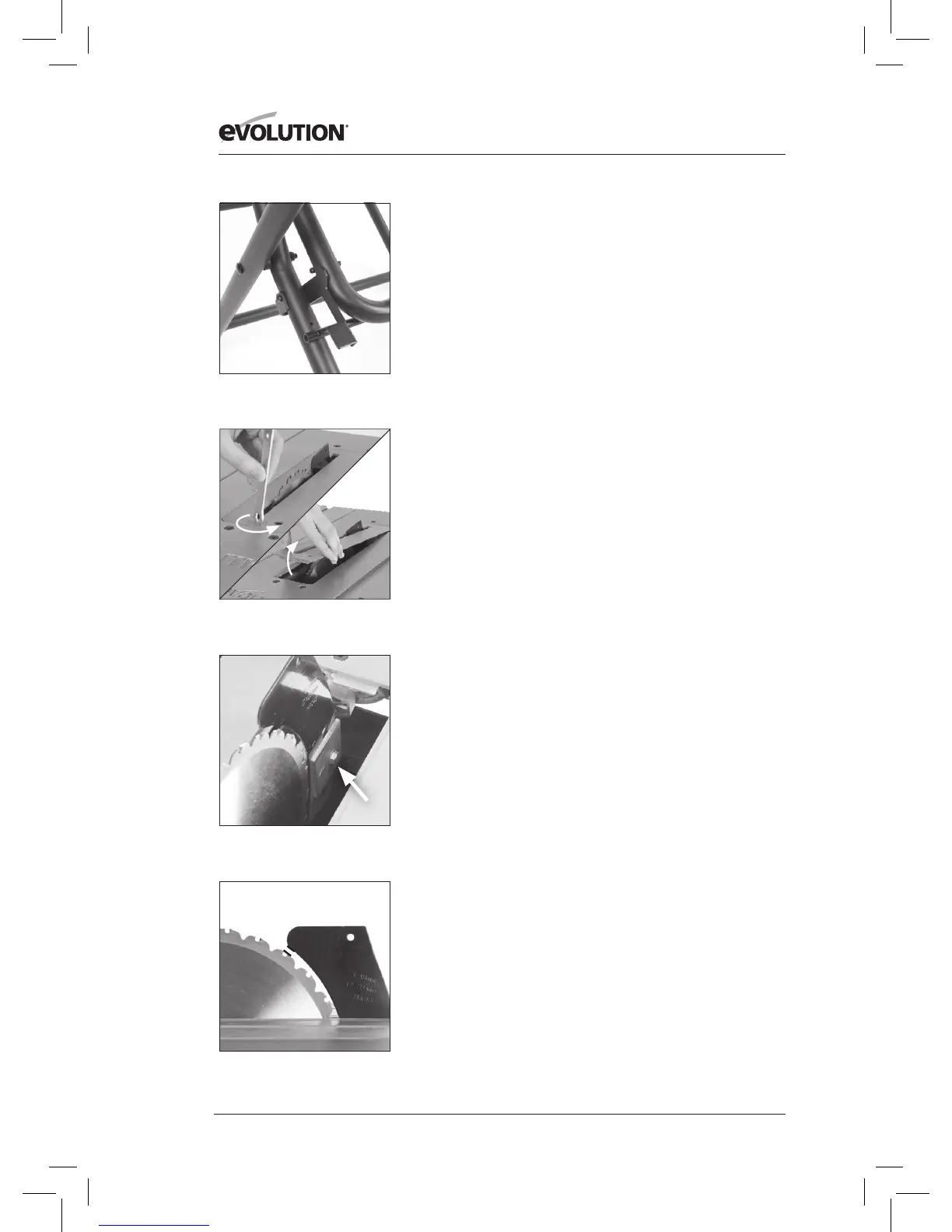

• AdjusttheRivingKnifesothatitisbetween3–5mmfrom

the saw blade. The tip of the riving knife shall not be lower

than 5mm from the tooth peak. (Fig. 16).

• Whencorrectalignmentisachievedtightenthexingbolt.

• Checkthesawbladerotatesfreelyandteetharewithin

3 - 5mm of the Riving Knife.

• Re-installtheTableAccessPlate.

Fig. 13

Fig. 16

Fig. 14

1.

2.

3 - 5mm

Fig. 15

Loading...

Loading...