18

www.evolutionpowertools.com

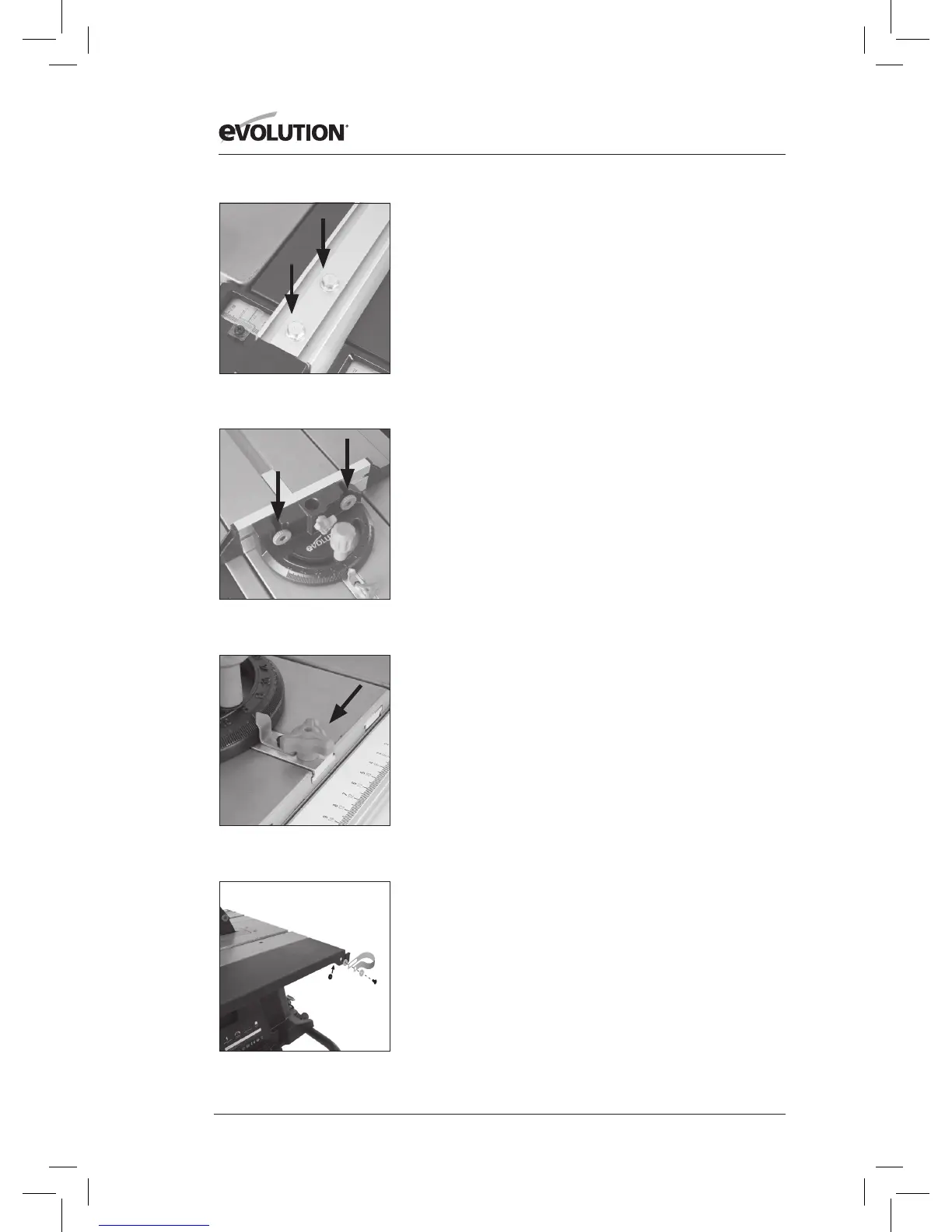

CHECKING/ADJUSTING THE RIP FENCE

When the Rip Fence has been attached to the machine, the Rip

Fence should be checked to ensure that it lies parallel to the blade.

• Raisethebladetoitsfullheight.

• Restastraight-edgeorsimilaragainsttheblade.

• BringtheRipFenceuptothestraight-edgeand

check for parallelism.

• Ifadjustmentisneeded,gainaccesstothetwohexheaded

screws located on the Rip Fence (Fig. 21).

• Loosenthesescrewsslightlyusingasuitablewrench,and

adjust the fence as required.

• Tightenandre-checktheRipFencewhencorrectalignment

has been achieved.

• Lowertheblade.

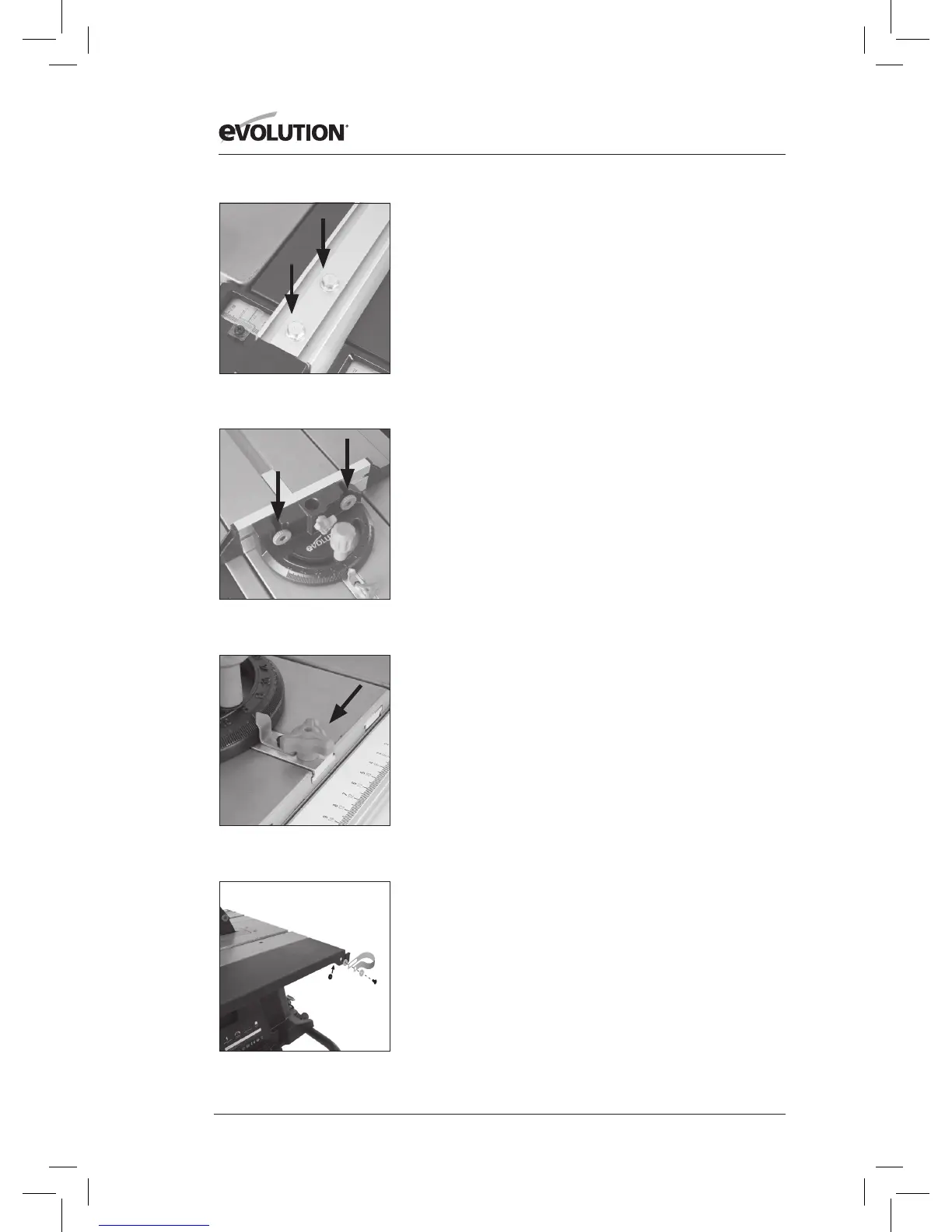

THE MITRE GAUGE

The Mitre Gauge labelled 10 has an adjustable Face Plate and

provision for a Hold Down Clamp labelled 11.

• InserttheHoldDownClampintothesocketintheMitre

Gauges main body and tighten the locking screw.

• AttachtheFacePlateoftheMitreGauge.

• Slidetheattachmentscrewsthroughthetwo(2)holesin

Mitre Gauges vertical face and secure in place with the

thumb nuts (Fig. 22).

• TheMitreGaugeisusuallyemployedontheLHsideofthe

table and runs in an inverted T slot in the table top.

• TheMitreGaugecanbelockedontotheSlidingCarriageby

screwing the locking screw into a hole located to the front

edge of the Sliding Carriage (Fig 23).

DUST EXTRACTION

• Attachoneendofthehosetothebladeguard.

• Attachthedustextractionhoseclip to the rear of the RH

(right hand) side table extension using the xings labelled

F, H and M (Fig. 24).

• Runthehosethroughthecliptotheportontherearof

the machine.

TRANSPORTING YOUR TABLE SAW

WARNING: Ensure that this procedure is only carried out with

the machine disconnected from the mains supply.

• Ensurethatthemachineisdisconnectedfromthemainssupply

and that the power cord is securely stored on the machine.

• Releasethelatchingpin.

• Graspthetransportationhandle(Fig. 25).

• Gentlyandslowlyliftthehandle,allowingthemachineto

maintain balance and stability.

• Wheelthemachinetoitsnewlocation

.

Fig. 24

Fig. 21

Fig. 22

Fig. 23

Loading...

Loading...