33

8.0 Maintenance

9.3 Maintenance work

9.3.1 Cleaning

To be performed by operator

CAUTION

Damage due to incorrect cleaning!

Therefore:

• Do not use any aggressive cleaning agents. Water used forclean-

ing including the chemical additives must be pH-neutral.

• Liquids must not touch the actuator during the retraction or ex-

tension.

• Only use additional cleaning materials listed by the manufacturer.

• No steam jets or pressure washers may be used for cleaning.

• Other cleaning agents or cleaning devices may only be utilized

with the manufacturer’s approval.

Clean line actuator:

1. Separate the actuator from the energy supply.

2. Clean dirty parts with a damp cloth.

9.3.2 Inspections and readings

To be performed by professional electrician

• The inspections and readings must be performed as re-

quired by the applicable standards and regulations. The list

of the applicable standards can be found in the appendix.

• The inspections must be documented (⮑ServiceLog).

Service log

• Complete the following entries in the service log:

• Nameoftheexecutingbody(company,department).

• Namesofthestaonduty.

• Identicationoftheactuator/system(type,serialnumber,

inventory number) and the respective accessories.

• Completed inspections and readings.

• Scope and results of the inspections.

• Measuringmethod,measuringdevice,measuringresults

for readings.

• Overall assessment.

• Dateandsignatureoftheassessingperson;personalcod-

ing is a viable alternative for IT applications.

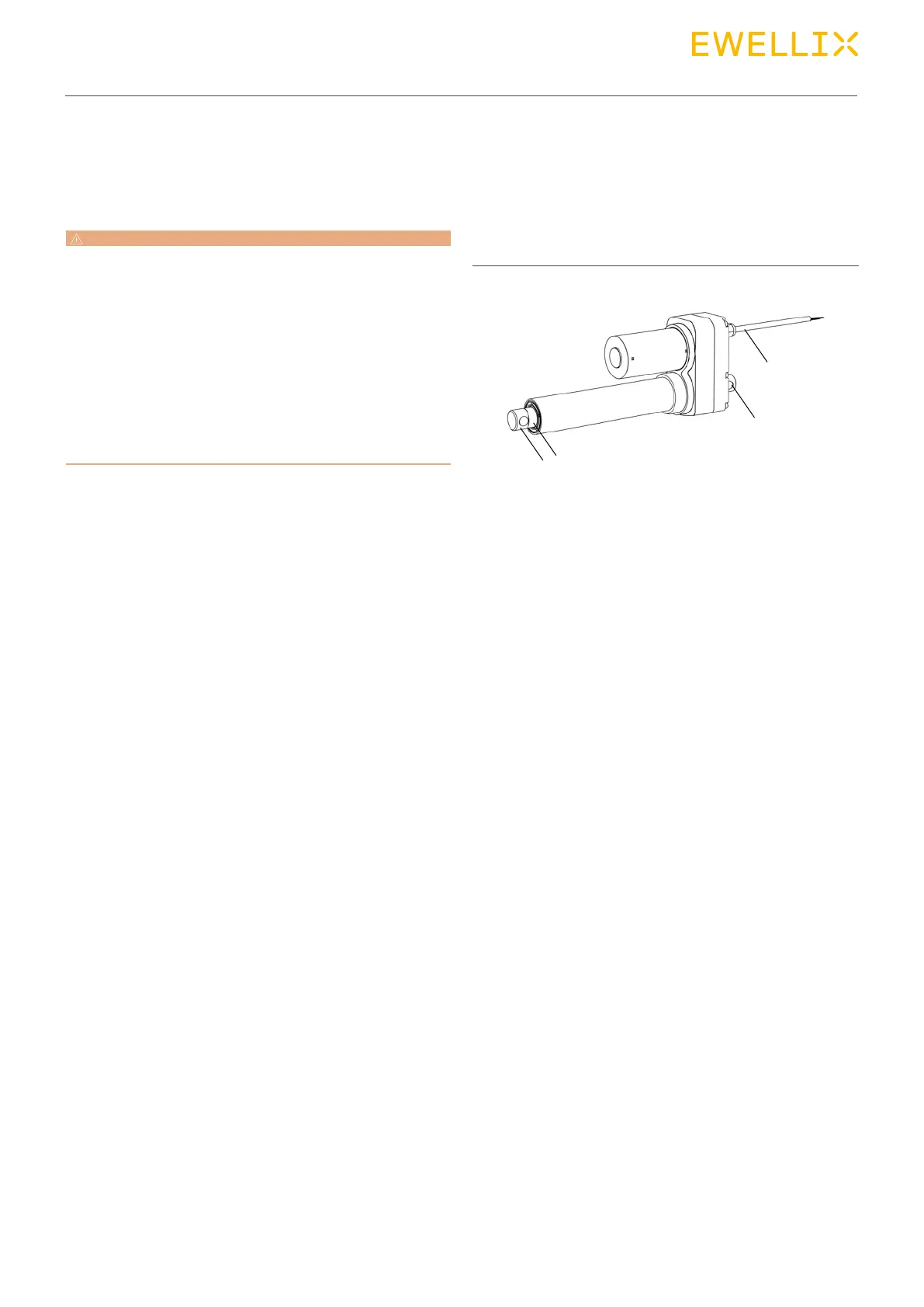

9.3.3 Check of visual condition

Tobeperformedbyqualiedpersonnel

1. Separate the actuator from the energy supply.

2. Check the following structural components for visible ex-

ternal damage:

Fig. 22

3. Notify processor or Ewellix in case of damage

4. If there is no damage and the processors/manufacturer

hasnotcommunicatedanyconcerns,reconnecttheac-

tuator to the power supply.

9.4 Measures after

completed maintenance

Uponcompletionofthemaintenancework,thefollowing

steps have to be performed prior to restarting the actuator.

1. Check all previously loosened screw connections for a

tightt.

2. Ensurethatalltools,materialandotherequipmentused

during maintenance have been removed from the work

area.

3. Clean work area and remove potential spills such as liq-

uids,processingmaterialorsimilar.

4. Ensure that all safety measures of the system work prop-

erly without a problem.

5. Check to be sure that all actuator and system functions

are operating correctly.

6. Document the the maintenance in the service log.

1. Checkconnectingcablesforcracks,cutsand

pinched sections

2. Checkhingeholeforcracks,deformationandbro-

ken pieces

3. Check stainless steel tube for scratches and inden-

tations

3

2

2

1

Loading...

Loading...