Maintenance

DriveSystemMaintenance

CheckingtheTirePressure

ServiceInterval:Every25hours/Monthly

(whichevercomesrst)

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

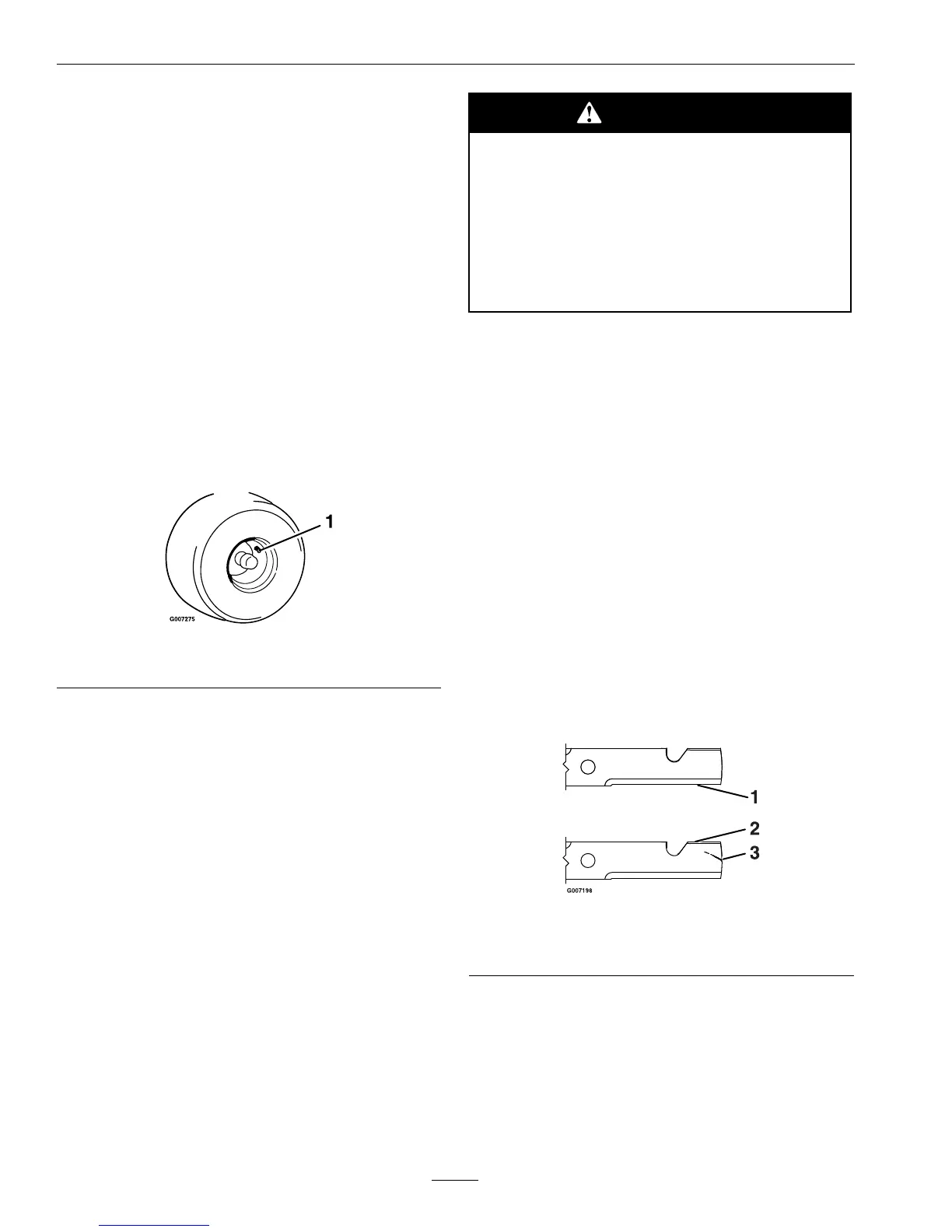

Checkthepressureatthevalvestem(Figure31).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

RearTires:13psi(90kPa)

FrontTires(casterwheels):

•Smooth:13psi(90kPa)

•Sawtooth:20psi(138kPa)

Figure31

1.Valvestem

MowerMaintenance

ServicingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedor

worn,replaceitimmediatelywithagenuineExmark

replacementblade.Forconvenientsharpeningand

replacement,youmaywanttokeepextrabladeson

hand.

WARNING

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,andmovethemotioncontrol

leversoutwardtotheneutralpositionandengage

parkingbrake.Stoptheengine,removethekey,and

disconnectthesparkplugwire(s)fromthespark

plug(s).

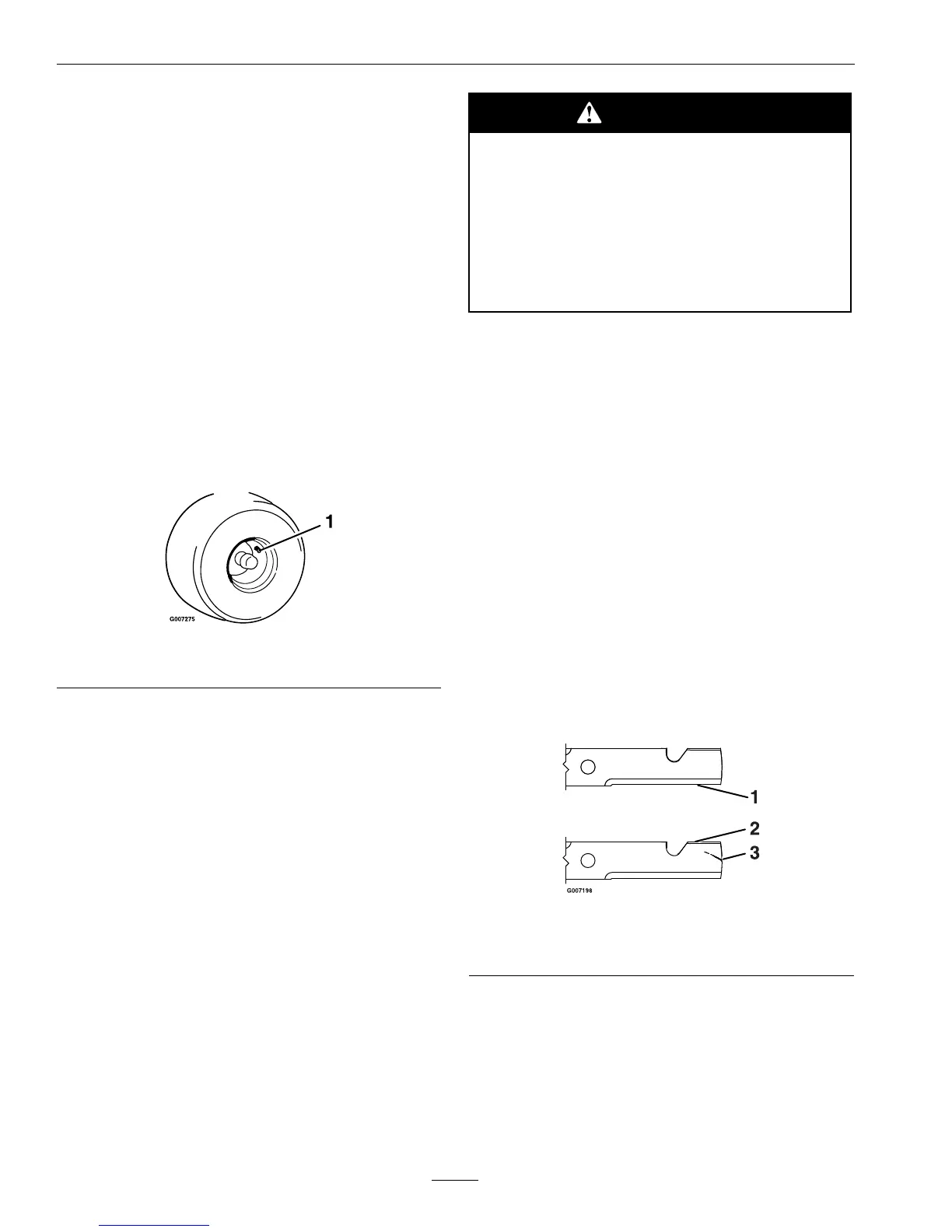

InspectingtheBlades

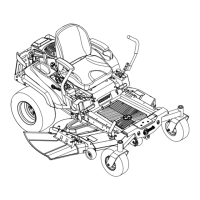

1.Inspectthecuttingedges(Figure32).Iftheedges

arenotsharporhavenicks,removeandsharpen

theblades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea.If

younoticeanydamage,wear,oraslotformingin

thisarea(item3inFigure32),immediatelyinstall

anewblade.

Figure32

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

CheckingforBentBlades

1.Rotatethebladesuntiltheendsfaceforwardand

backward(Figure33andFigure34).Measure

fromalevelsurfacetothecuttingedge,ofthe

blades.Notethisdimension.

38

Loading...

Loading...