Maintenance

Pre-Maintenance

Procedures

RaisingtheSeat

Placethemotioncontrolleversouttotheneutral

lockposition,engagetheparkingbrake,andliftthe

seatforward.

Thefollowingcomponentscanbeaccessedbyraising

theseat:

•Serialplate

•Servicedecal

•Seatadjustmentbolts

•Fuellter

•Batteryandbatterycables

PeriodicMaintenance

Lubrication

GreasingtheBearings

ServiceInterval:Every25hours/Monthly

(whichevercomesrst)

GreaseType:NLGIgrade#2multi-purposegun

grease.

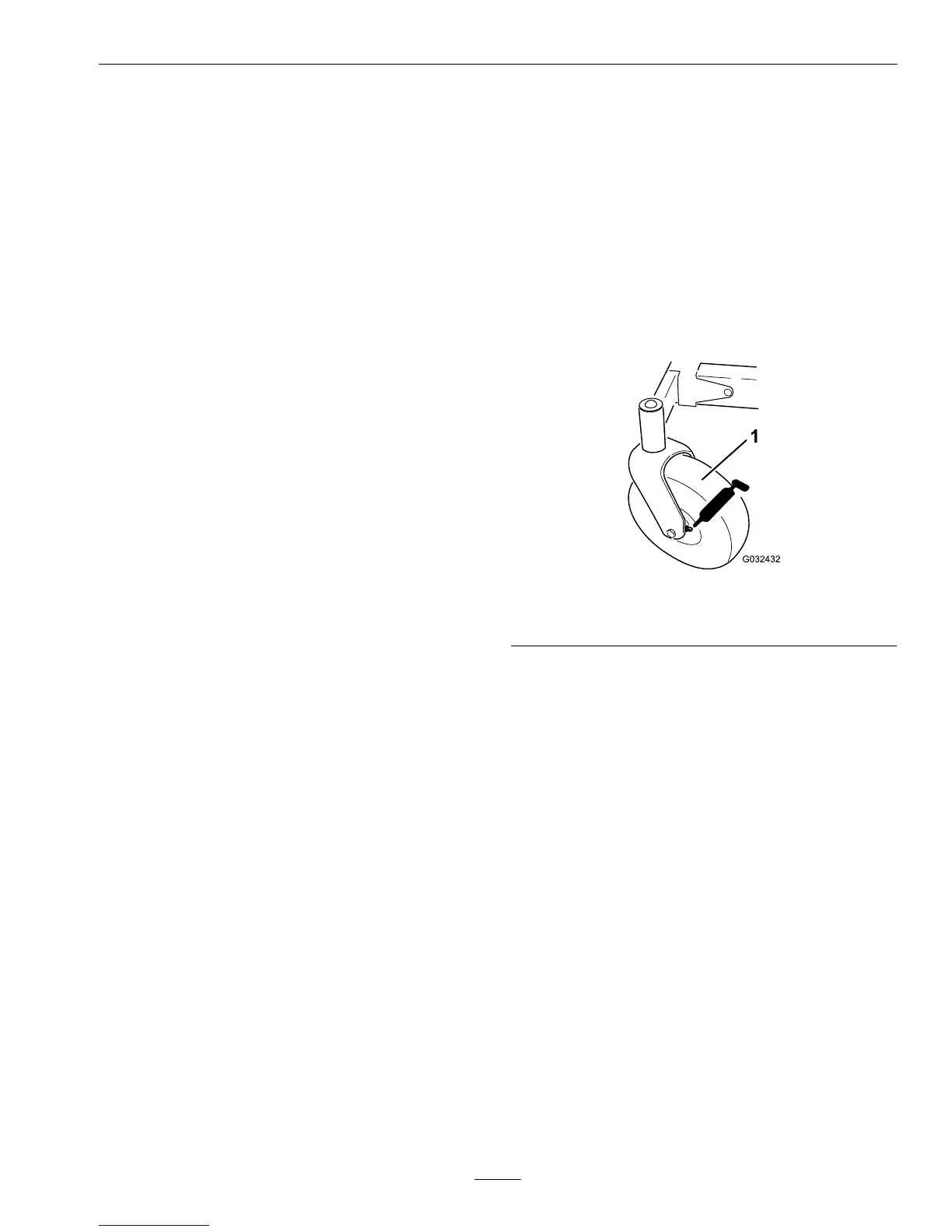

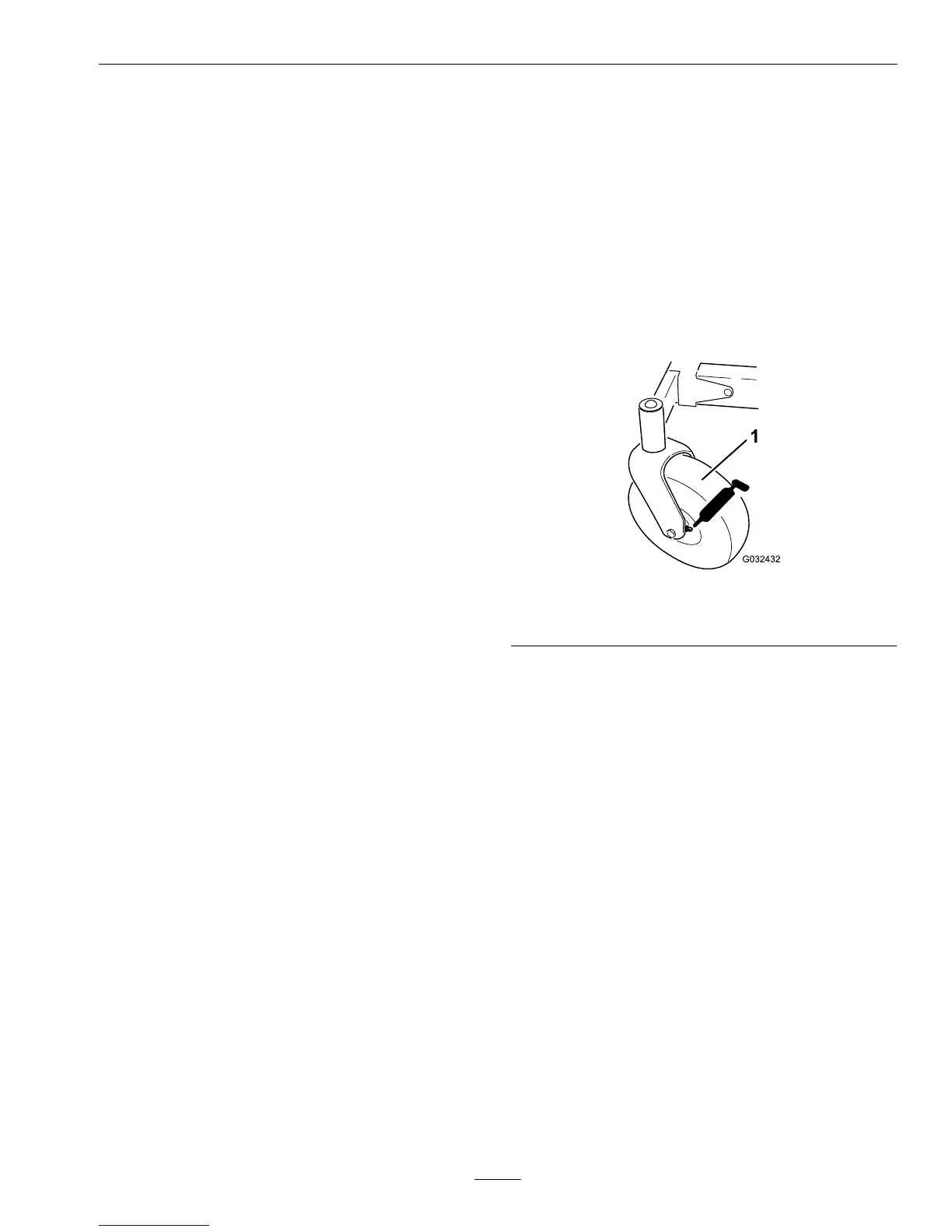

Greasethefrontcasterwheels(Figure26).

g032432

Figure26

1.Frontcastertire

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversouttotheneutral

lockposition,engageparkingbrake,stopthe

engine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffofthefrontofthetting(s).

4.Wipeupanyexcessgrease.

EngineMaintenance

Important:Ifyouareusingamachinewith

anExmarkengineabove5,000ft(1500m)fora

continuousperiod,ensurethattheHighAltitude

Kithasbeeninstalledsothattheenginemeets

CARB/EPAemissionregulations.TheHigh

AltitudeKitincreasesengineperformancewhile

preventingsparkfouling,hardstarting,and

increasedemissions.Onceyouhaveinstalled

thekit,attachthehigh-altitudelabelnextto

theserialdecalonthemachine(reference

Figure1).ContactanAuthorizedServiceDealer

37

Loading...

Loading...