Maintenance

Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedor

worn,replaceitimmediatelywithagenuineExmark

replacementblade.Forconvenientsharpeningand

replacement,youmaywanttokeepextrabladeson

hand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,andmovethemotioncontrol

leversoutwardtoneutrallock,andengagethe

parkingbrake.Stoptheengine,removethekey,and

disconnectthesparkplugwire(s)fromthespark

plug(s).

InspectingtheBlades

1.Inspectthecuttingedges(Figure61).Iftheedges

arenotsharporhavenicks,removeandsharpen

theblades;refertoSharpeningtheBlades.

2.Inspecttheblades,especiallythecurvedarea.If

younoticeanydamage,wear,oraslotformingin

thisarea(item3inFigure61),immediatelyinstall

anewblade.

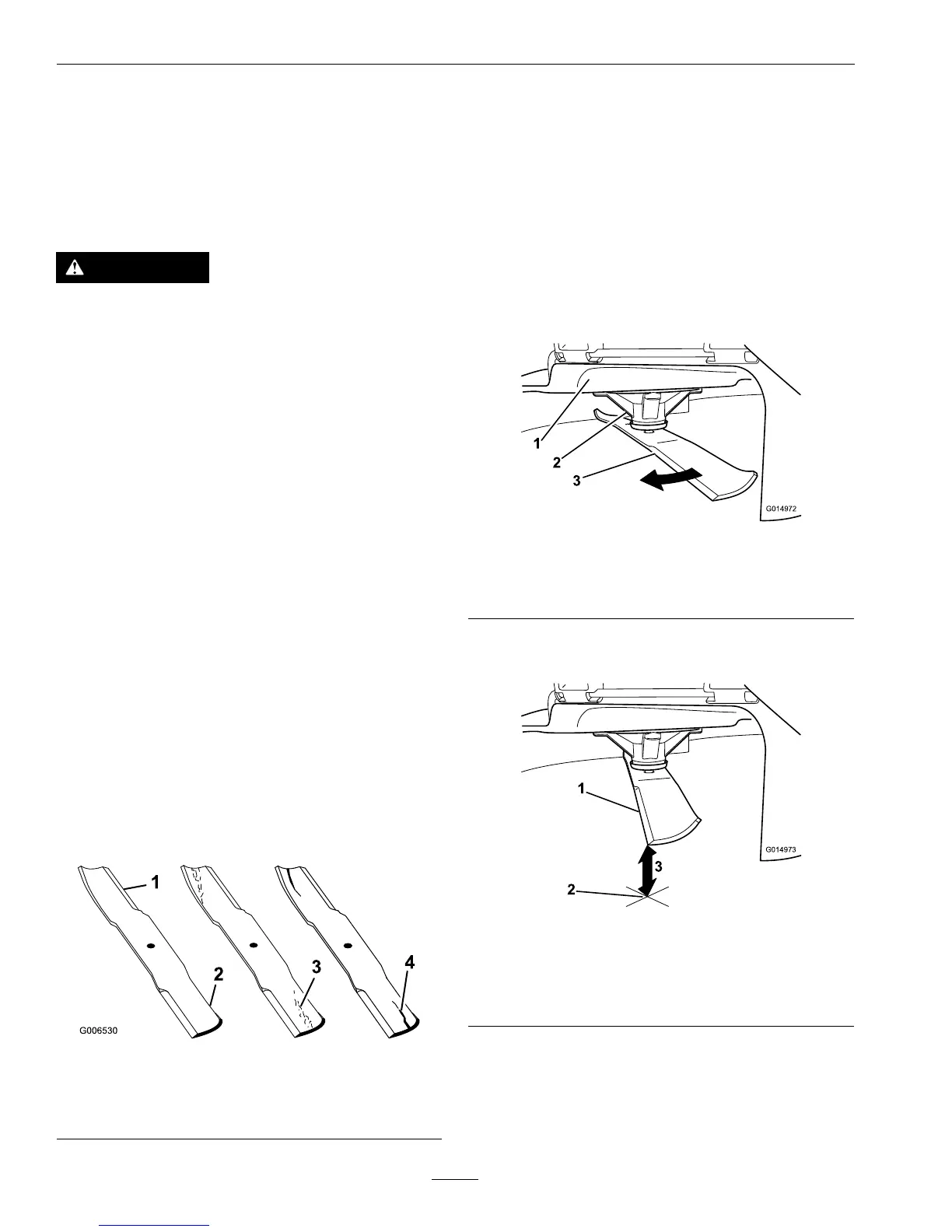

g006530

Figure61

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedglovesorother

adequatehandprotectionslowlyrotatebladeto

bemeasureintoapositionthatallowseffective

measurementofthedistancebetweenthecutting

edgeandthelevelsurfacethemachineison.

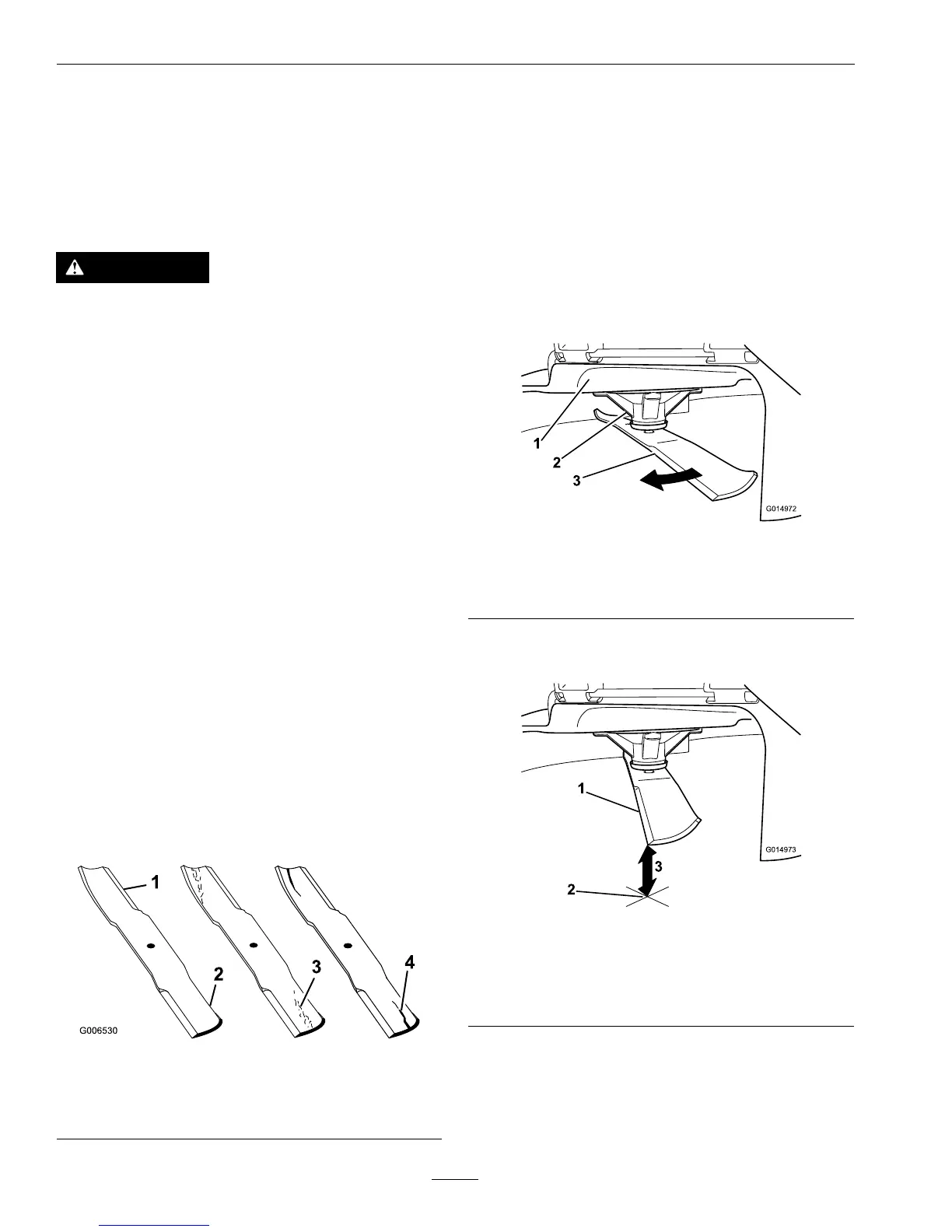

g014972

Figure62

1.Deck3.Blade

2.Spindlehousing

3.Measurefromthetipofthebladetotheat

surfacehere.

g014973

Figure63

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

4.Rotatethesameblade180degreessothatthe

opposingcuttingedgeisnowinthesameposition.

56

Loading...

Loading...