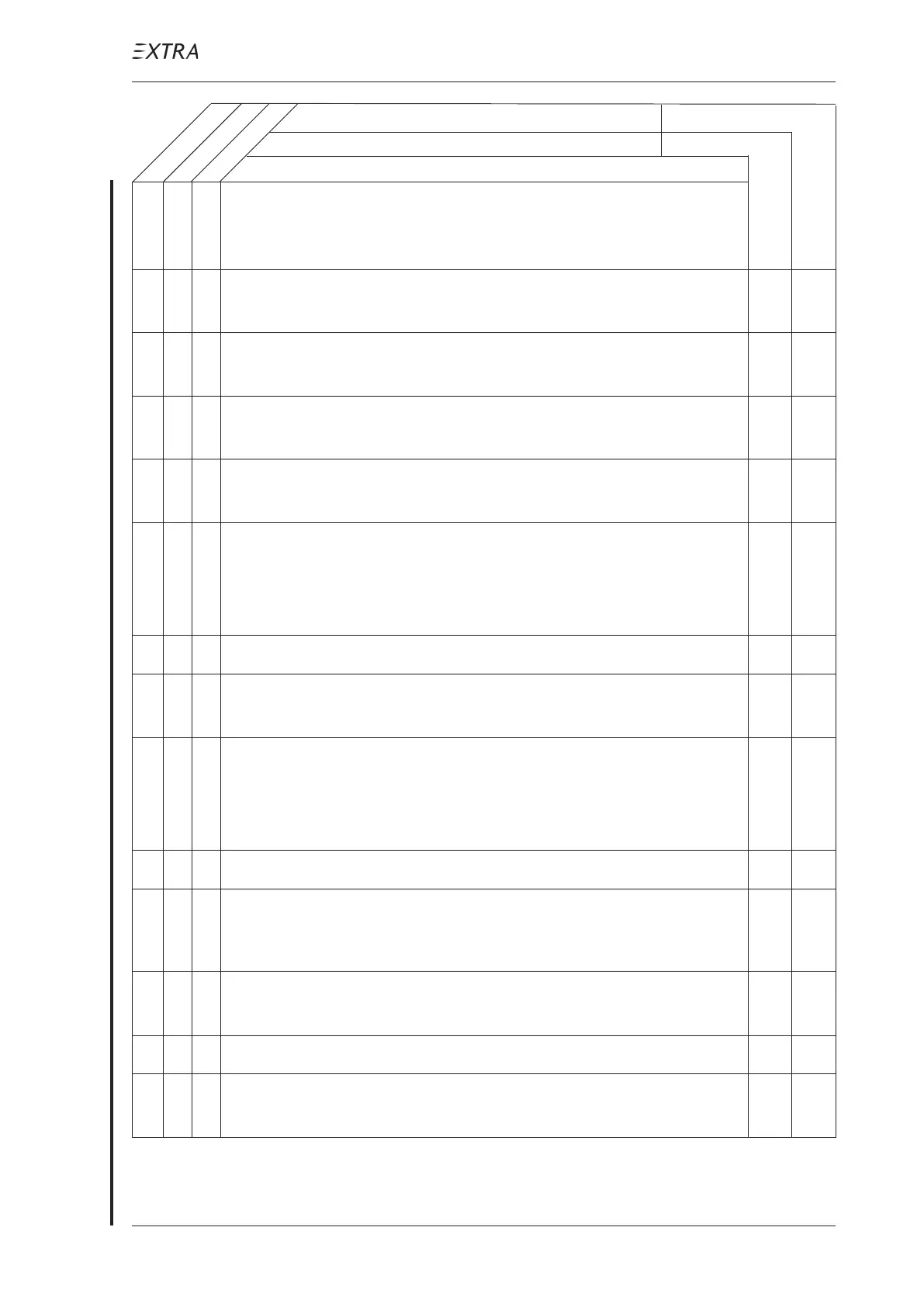

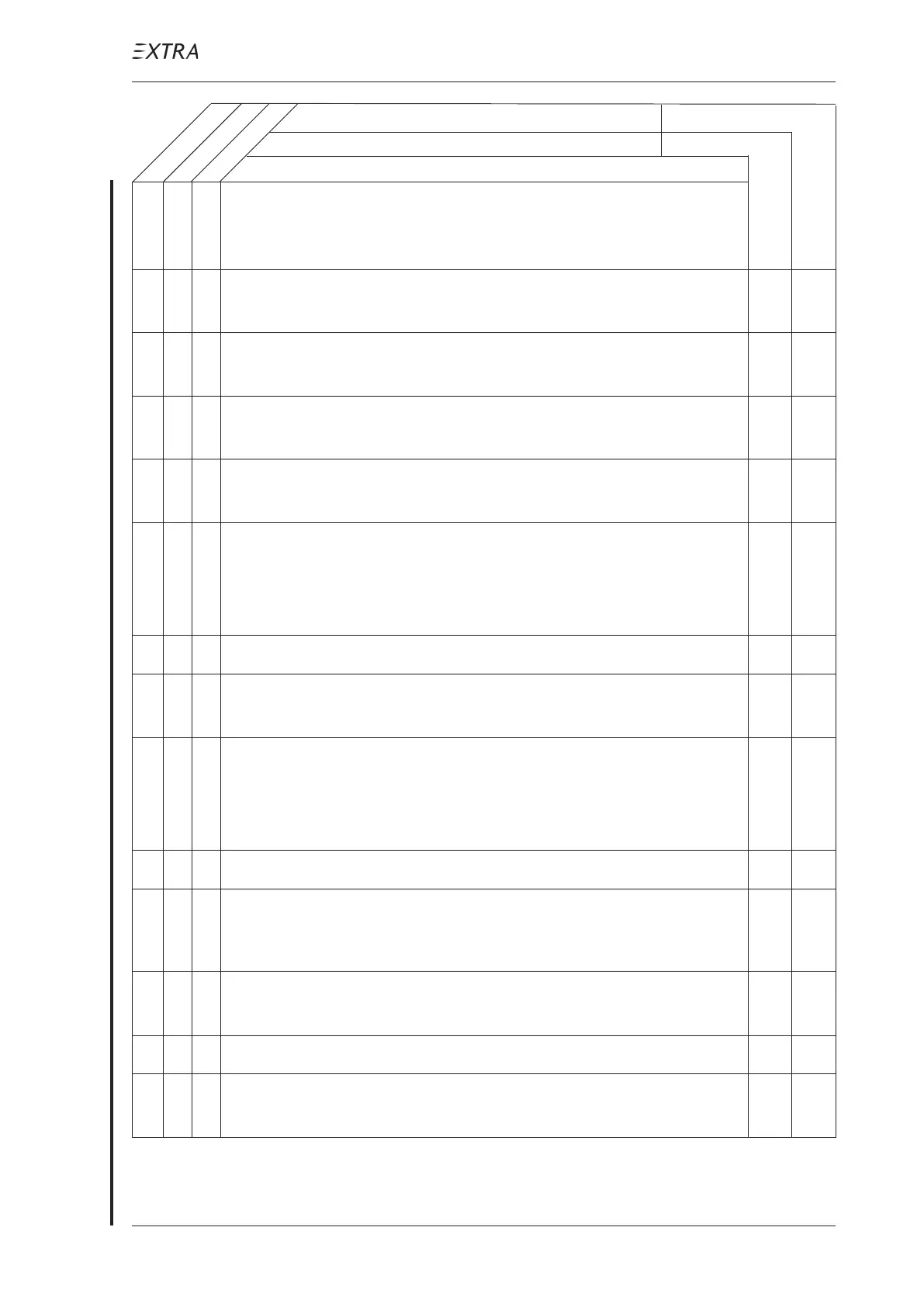

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 16

PAGE DATE: 1. August 2014

O 23 Inspect ignition harness for general condition, free from

fraying or chafing and insulators for high tension leakage and

continuity.

O 24 Inspect SlickSTART, refer to Unison Operation, Maintenance,

and Troubleshooting Manual.

O 25 Inspect magneto and accessories according to Slick Magneto

Maintenance and Overhaul Manual.

O 26 Check fuel injector for general condition, clean fuel inlet

screen.

O O 27 Inspect intake gaskets and seal-rings for leaks and flanges for

tightness.

O O 28 Inspect flexible fuel lines, fuel injection lines and fittings for

leaks, security, chafing, dents, and cracks (refer to Lycoming

SB 342 each 100h; replace or overhaul as required or at engine

overhaul). Check fire protection.

O O 29 Check fuel system for leaks.

O

1

O O 30 Remove, clean and inspect gascolator screen and fuel filter

bowl.

O O 31 Inspect throttle, mixture, and propeller governor controls for

security, travel, and operating conditions. Observe the hints

given in the Inspections-paragraph of chapter 20-10-09 Con-

trol Cables.

O

2

O 32 Inspect all external exhaust surfaces for signs of leakage.

O

2

O 33 Inspect all external exhaust joints, slip joints, clamps, cou-

plings for misalignment, warpage, broken, loose or missing

fasteners, clamps, gaskets or seals and abnormal wear.

O

2

O 34 Inspect all interior exhaust areas for blockage, restrictions,

dents or protrusions into the exhaust flow path.

O

2

O 35 Inspect muffler, heat exchanger for general condition.

O

2

O 36 Inspect exhaust stack to flange interface for cracks in welds or

weld heat affected area, blown out or missing gaskets.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

1 clean at least every 90 days

2 at engine replacement

Loading...

Loading...