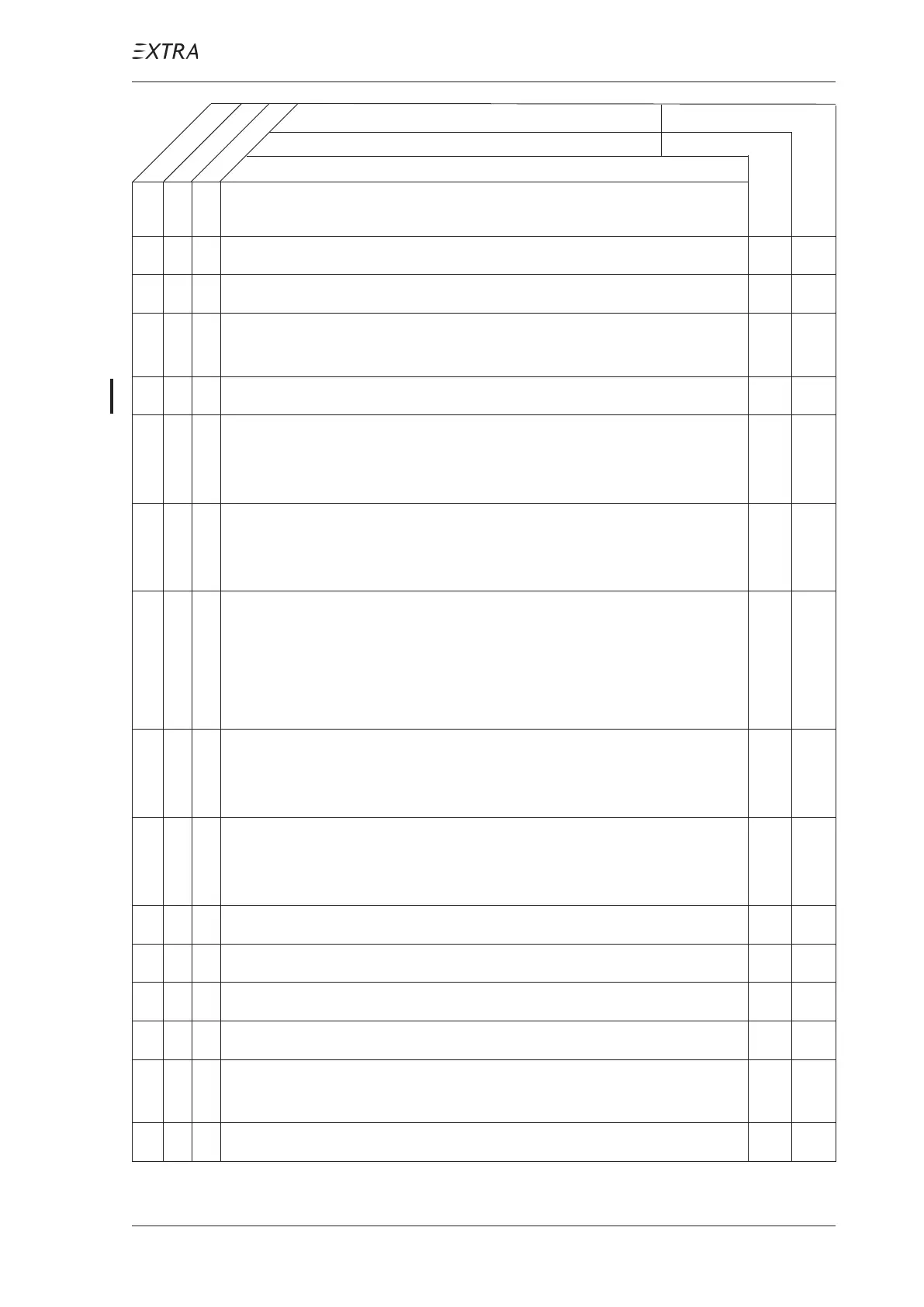

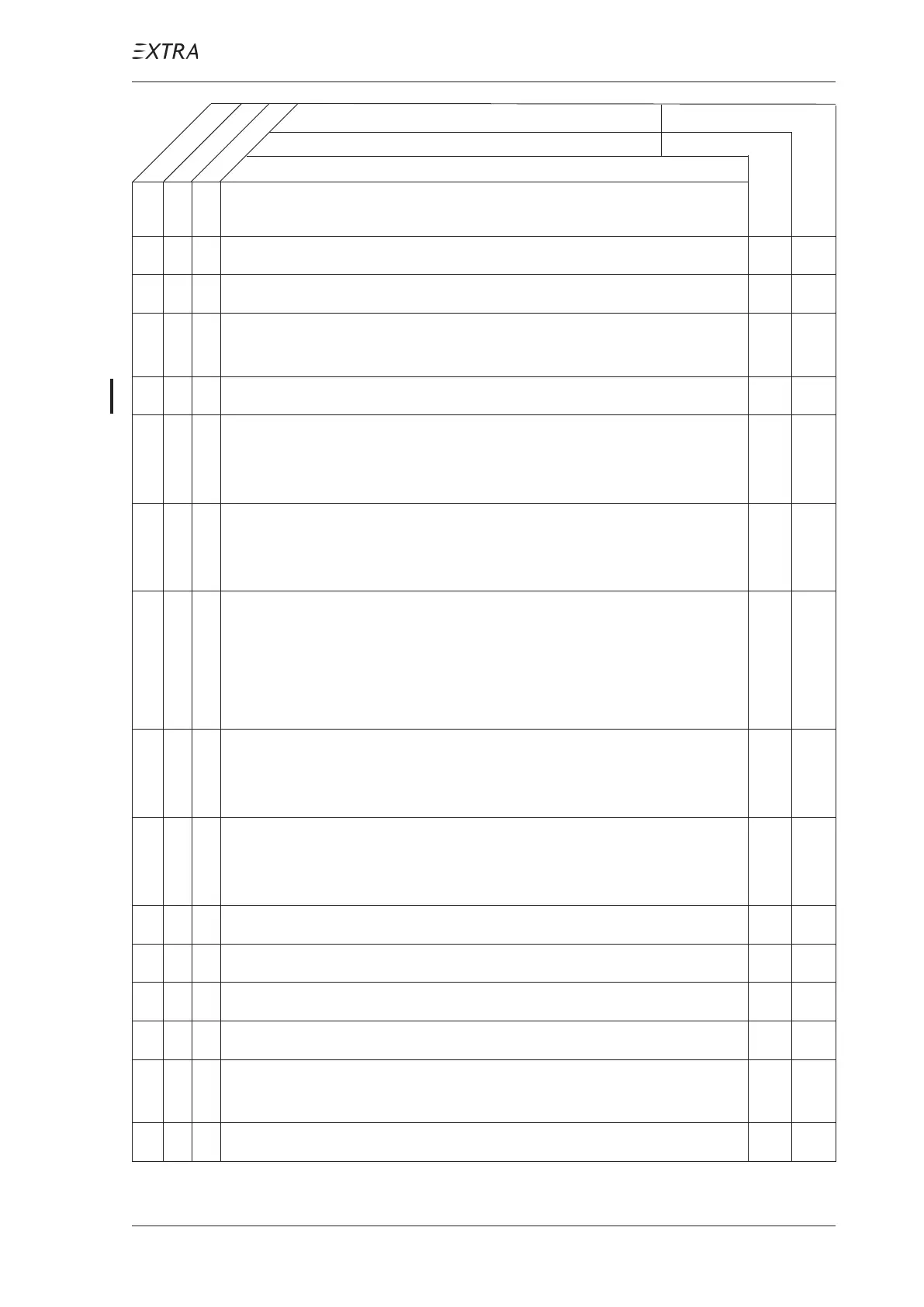

MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 23

PAGE DATE: 1. August 2014

Brake system

O O 1 Inspect brake assemblies for general condition.

O O 2 Inspect master cylinders for leaks.

O 3 Inspect brake system plumbing for leaks and hoses for bulges

and deterioration.

O 4 Lubricate anchor bolts using Silicone-based lubricant.

O O 5 Visually inspect the brakes for corrosion, cracks, or other

visible damage. Check inlet fitting bosses and anchor bolt lugs

for cracks.

O O 6 Check back plate attachment bolts to insure they are properly

torqued and have not worked loose. Gaps between the back

plate and cylinder would be evidence of this.

O O 7 Check fit of brake cylinder anchor bolts in torque plate

bushings for sloppiness. This can be accomplished by grasping

the cylinder and moving it; slight movement is normal.

Excessive movement is cause for removal and detailed inspec-

tion.

O O 8 Linings should be visually checked for extreme chipping on

the edges. Lining worn to a minimum thickness of 0.100 inch

(2.54 mm) must be replaced.

O O 9 Visually check torque plate for corrosion, cracks, loose an-

chor bolt bushings, or other visible damage. Anchor bolt

bushings must be flat against torque plate surface.

O O 10 Check for any brake fluid leaks.

O O 11 Check brake fluid level.

Tail-wheel landing gear

O O 1 Check tail-wheel landing gear for general condition.

O O 2 Check tail-wheel landing gear spring for dents, cracks, and

delaminations.

O O 3 Check tail-wheel rubber tire condition.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

each 50 hours

Loading...

Loading...