MAINTENANCE MANUAL EXTRA 300/SC

CHAPTER 05

PAGE 25

PAGE DATE: 1. August 2014

SCHEDULED MAINTENANCE CHECKS

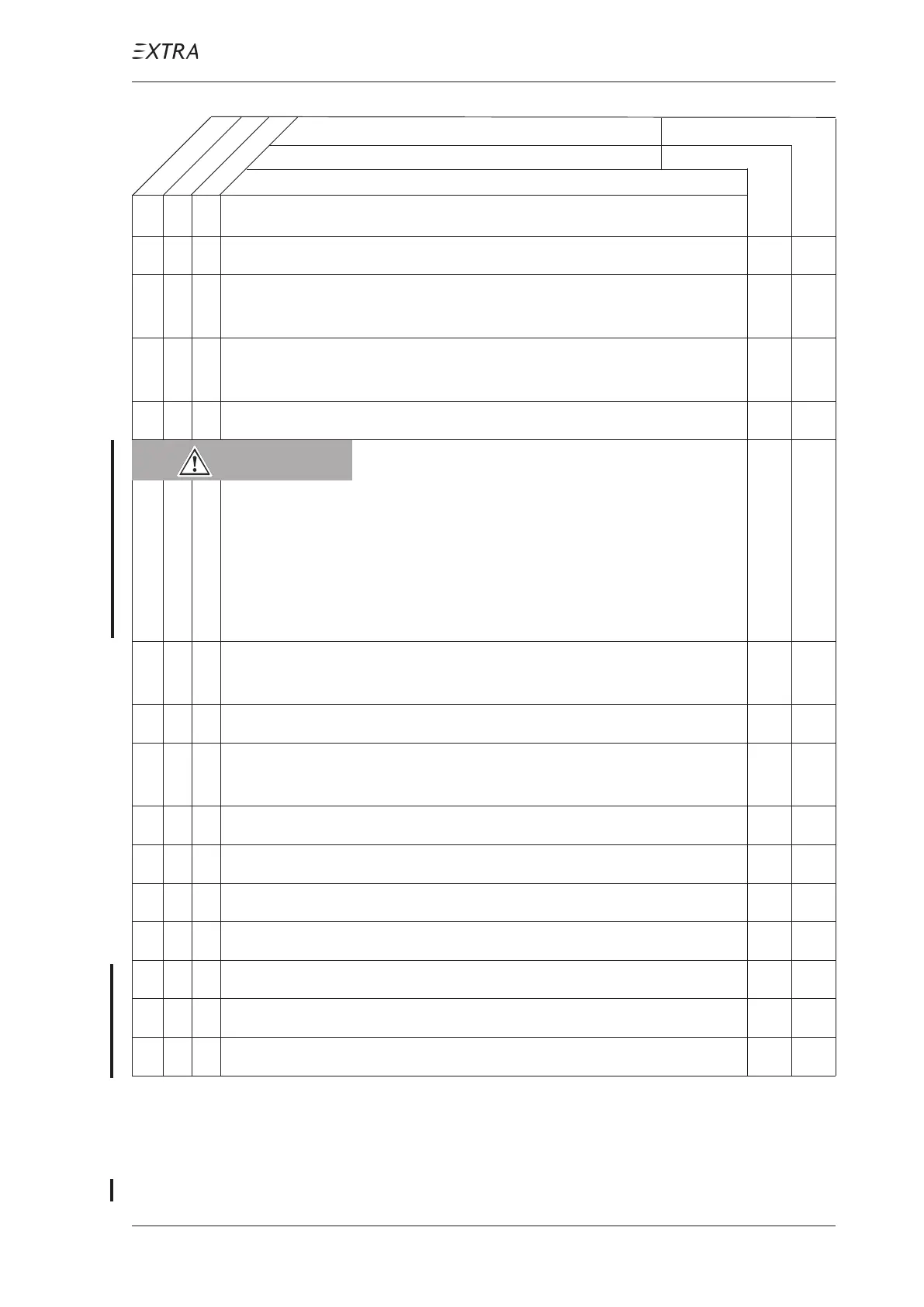

Maintenance Checks Schedule

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 100 hours

each 50 hours

Instruments

O 1 Inspect panel mounting for security and safety.

O 2 Check operation, mounting, and wiring of switches for condi-

tion and safety.

O 3 Check automatic circuit breaker mounting and wiring for

condition and safety.

4 Reserved

WARNING Risk of blinding due to LED radiation.

Do not stare into beam.

Wear eye protection.

O 5 Check wing-tip strobe lights for security and operation. If any

one LED fails, the units must be replaced. Inspect the lens.

Replace the unit if there is excessive scratching, discoloration

or cracking.

O O 6 Inspect compass and compass deviation card for proper indi-

cation and compensation.

O

1

7 Magnetic compass compensation.

O 8 Check pitot/static air pressure lines for condition and leaks,

perform operational check.

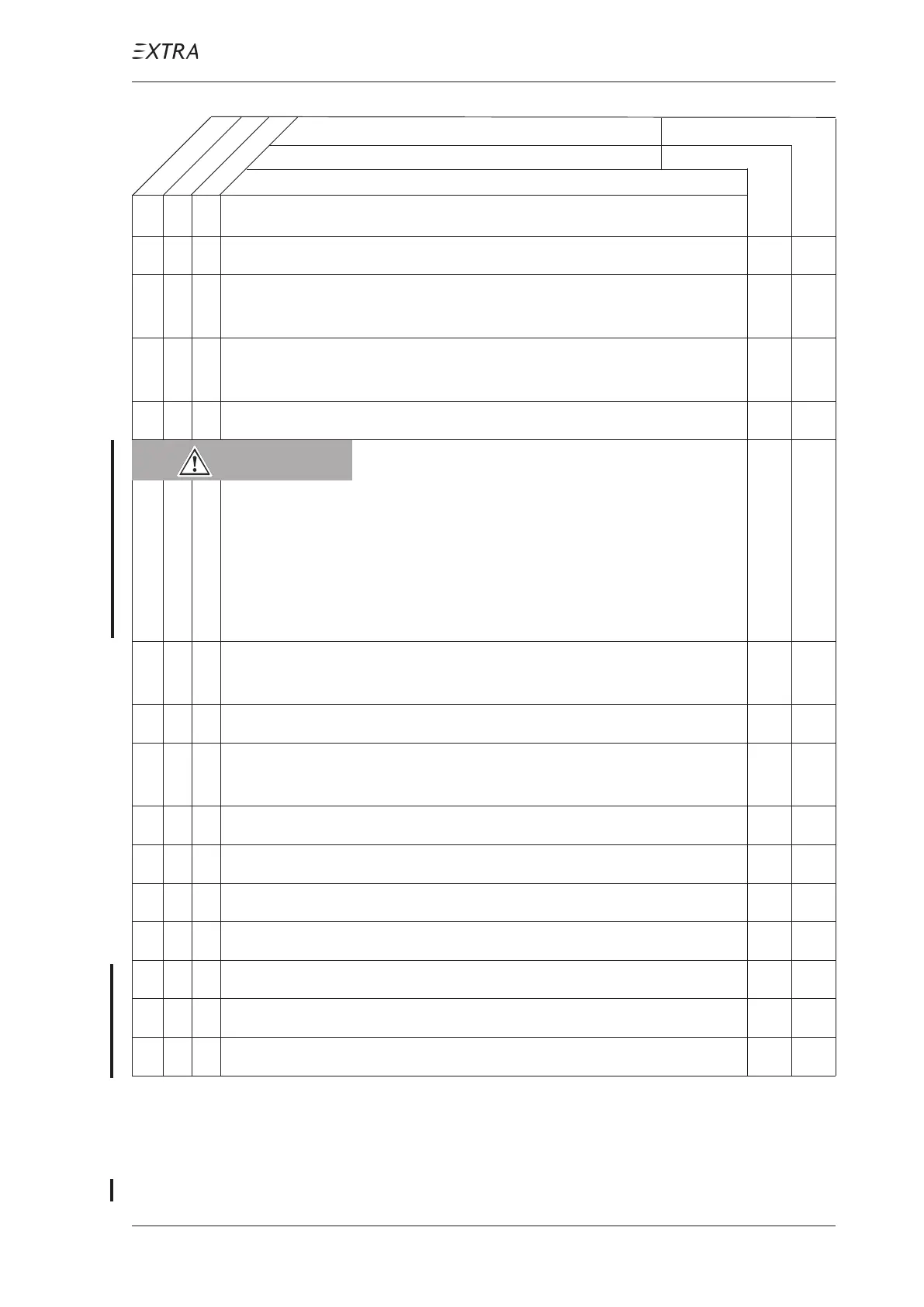

Electrical system

O O 1 Check engine bonding.

O O 2 Check tank bonding (wing- and center tank).

O 3 Check system wiring free from fraying or cracks.

O 4 Visually inspect battery and attachment.

O O 5 Charge battery as per CONCORDE Service Instructions.

O

2

6 Perform battery capacity check.

1 Annual, each twelve calendar month

2 Annual, each twelve calendar month or 200 h, whichever comes first

Loading...

Loading...