AUX MODE

7

Chapter: 2 Section: Page

2.3 TOOL TABLE OR ZERO OFFSET TABLE

The CNC has an internal table which, depending on the setting of machine parameter

"P60(5)", may be used as tool table, "P60(5)=0", or zero offset table, "P60(5)=1".

Each one of 10 table addresses (1 through 10) has 2 fields: one for the X axis and

the other one for the Y axis.

When setting "P60(5)=0", tool table, the address number matches the tool number.

Both fields indicate tool length along X and Y (respectively). The CNC will take the

table values and will apply tool length along both axes.

When setting "P60(5)=1", zero offset table, each table address can be allocated a new

Part Zero. This part zero will be referred to Machine Reference Zero (home) at the

distance indicated in the Y and Y fields.

To access this table, press: [AUX MODE] [2]

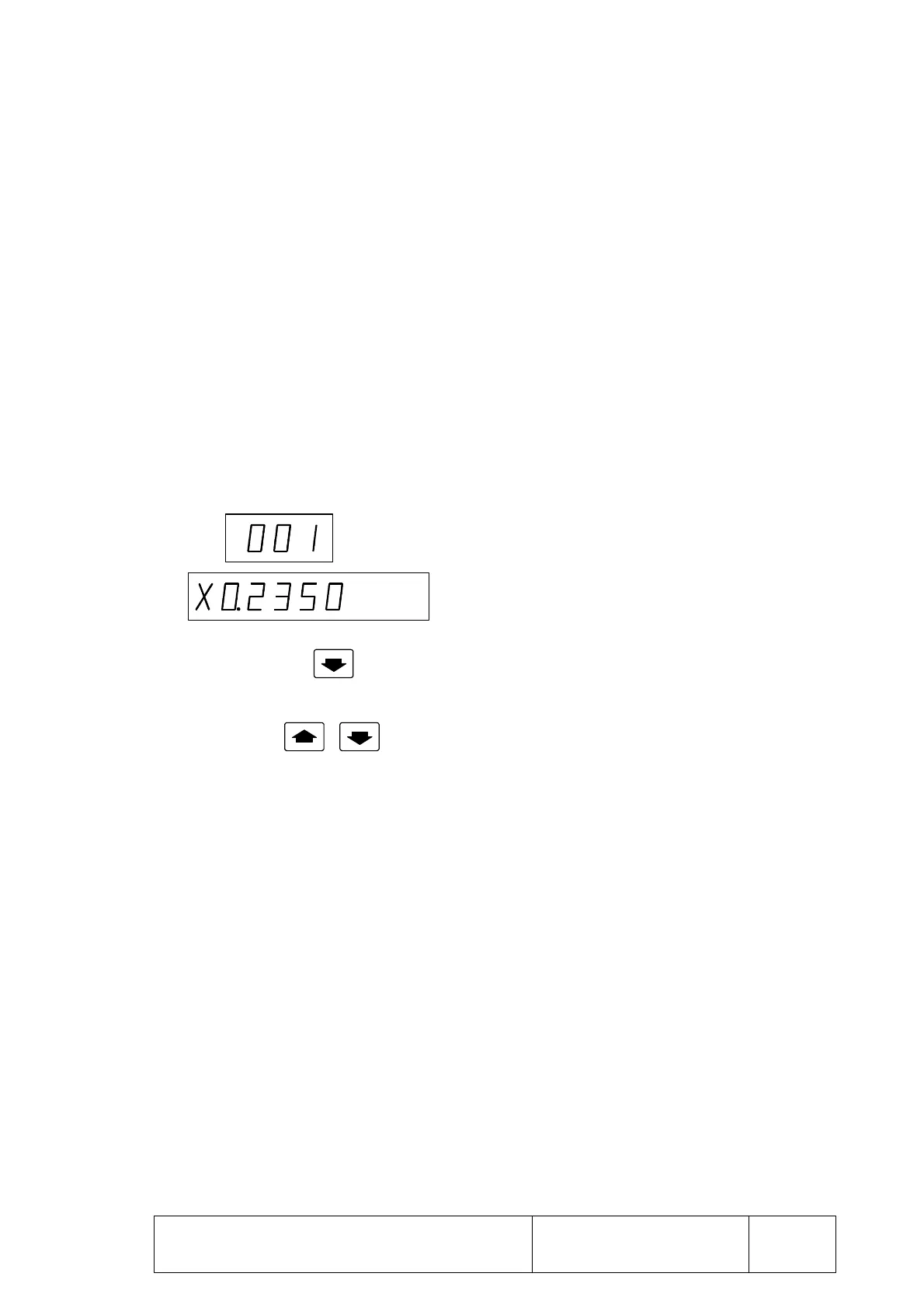

The displayed information looks like this:

The upper display shows the first table address.

The lower display shows the X field value for this

address.

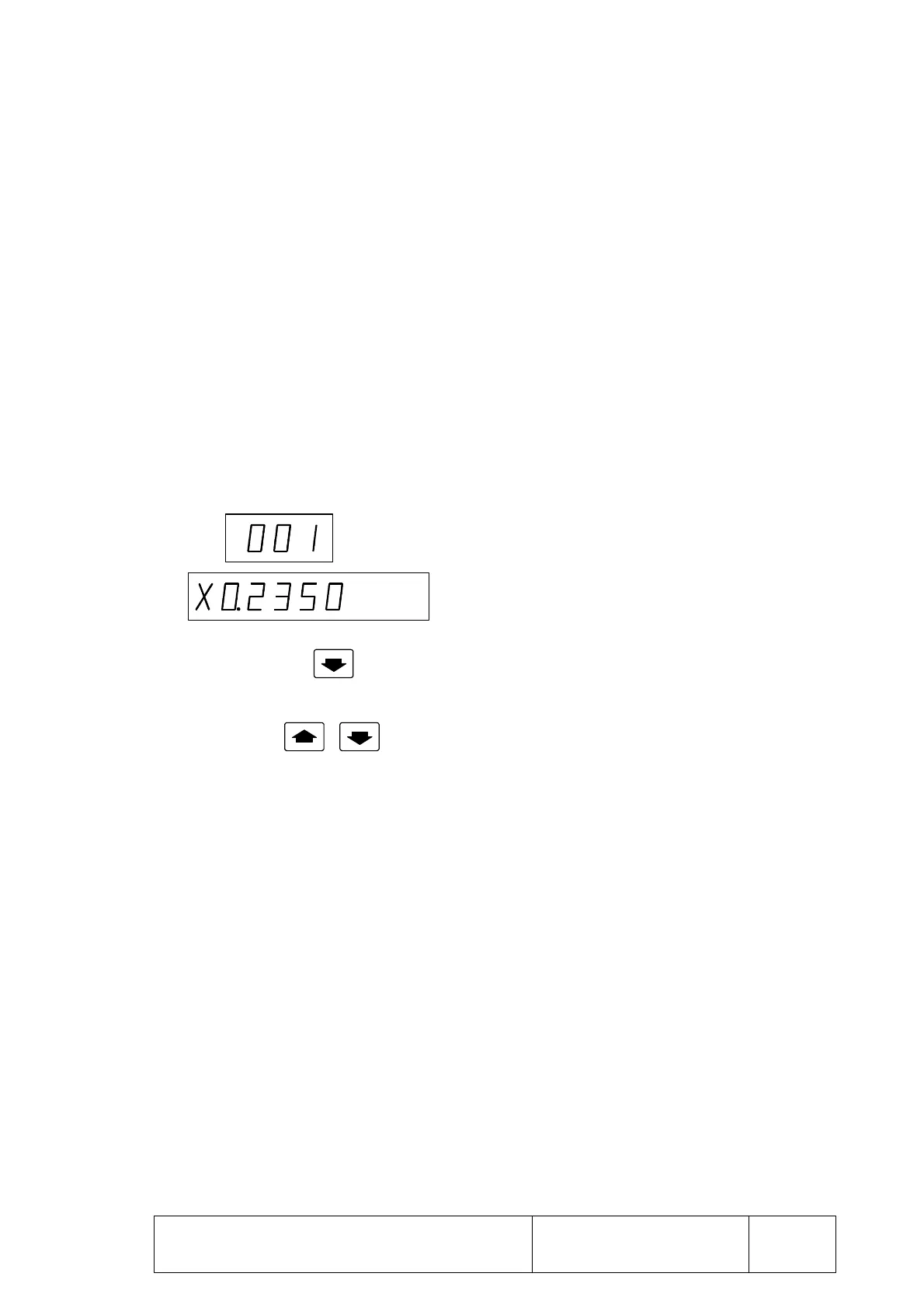

When pressing , the CNC shows the value for the Y field.

Use one of the following methods to display another table address:

* Use the keys.

* Press the [CL] key twice to clear the current display. Then, key in the desired

table address and press [RECALL]. The CNC will display this new address.

To edit the values of the X or Y fields, proceed as follows:

* Press [CL] and the CNC will clear the lower display.

* Key in the desired value.

* Press [ENTER] for the new value to be "entered" in the table.

TOOL TABLE OR

Loading...

Loading...