Section:

Page

PROGRAMMING2

Chapter: 6

PROGRAMMING FORMAT

6.1.1 PREPARATORY G FUNCTIONS

The preparatory functions are always programmed at the beginning of the block and

they serve to determine the geometry and work conditions of the CNC.

They are defined by means of the G function and each block may contain up to 4 of

them. The functions must be separated by a period G 1.7.90

If incompatible G functions are programmed in the same block, the CNC assumes the

last one.

The possible G functions are:

Attention:

The letter "M" means modal. This means that once the G function is executed,

it remains active until another incompatible G function or M30 is executed

or on an Emergency or a Reset.

The letter "D" means "By Default". This means that the it is assumed by

the CNC on power-up, after executing an M30 or after an Emergency or

a Reset.

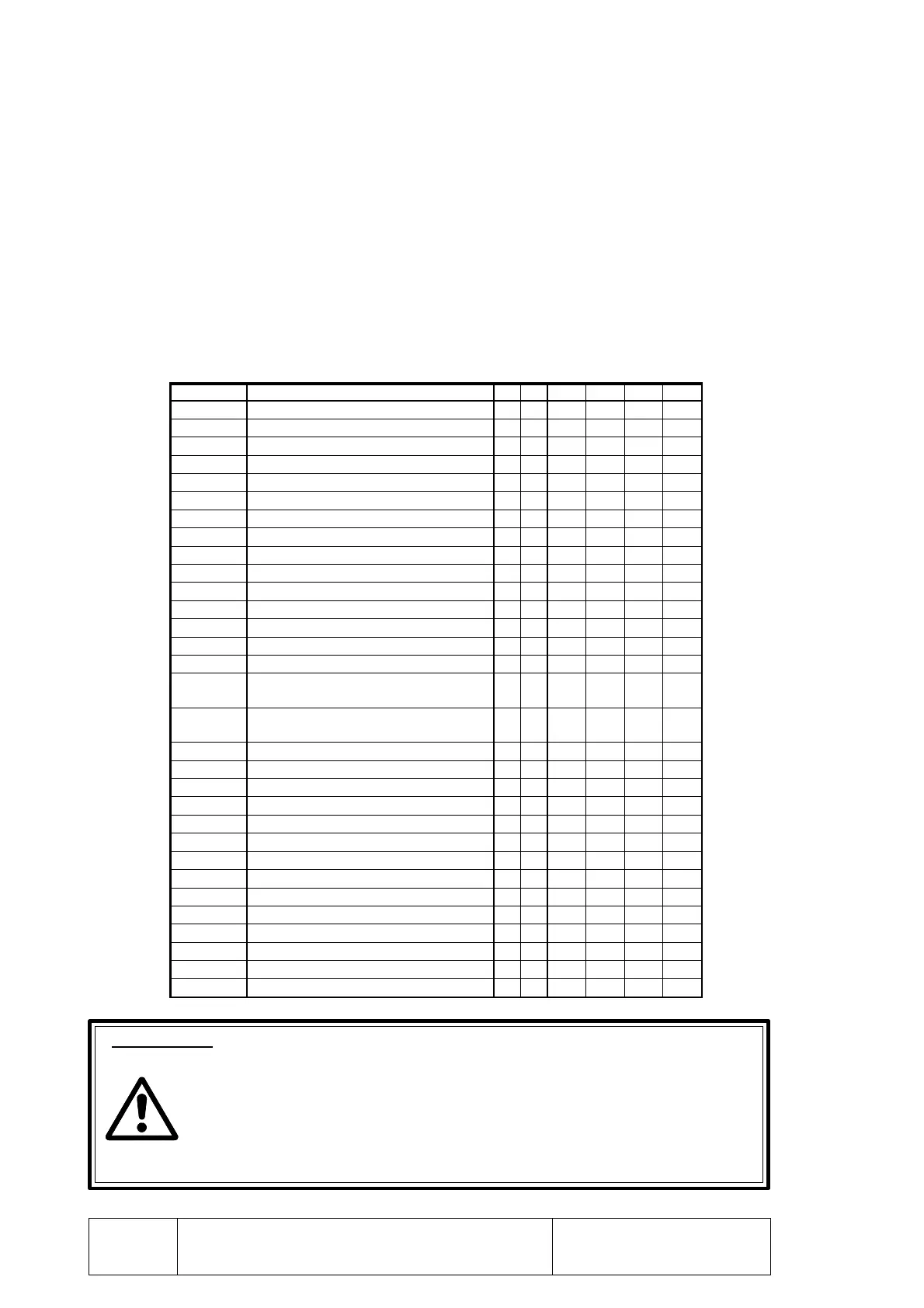

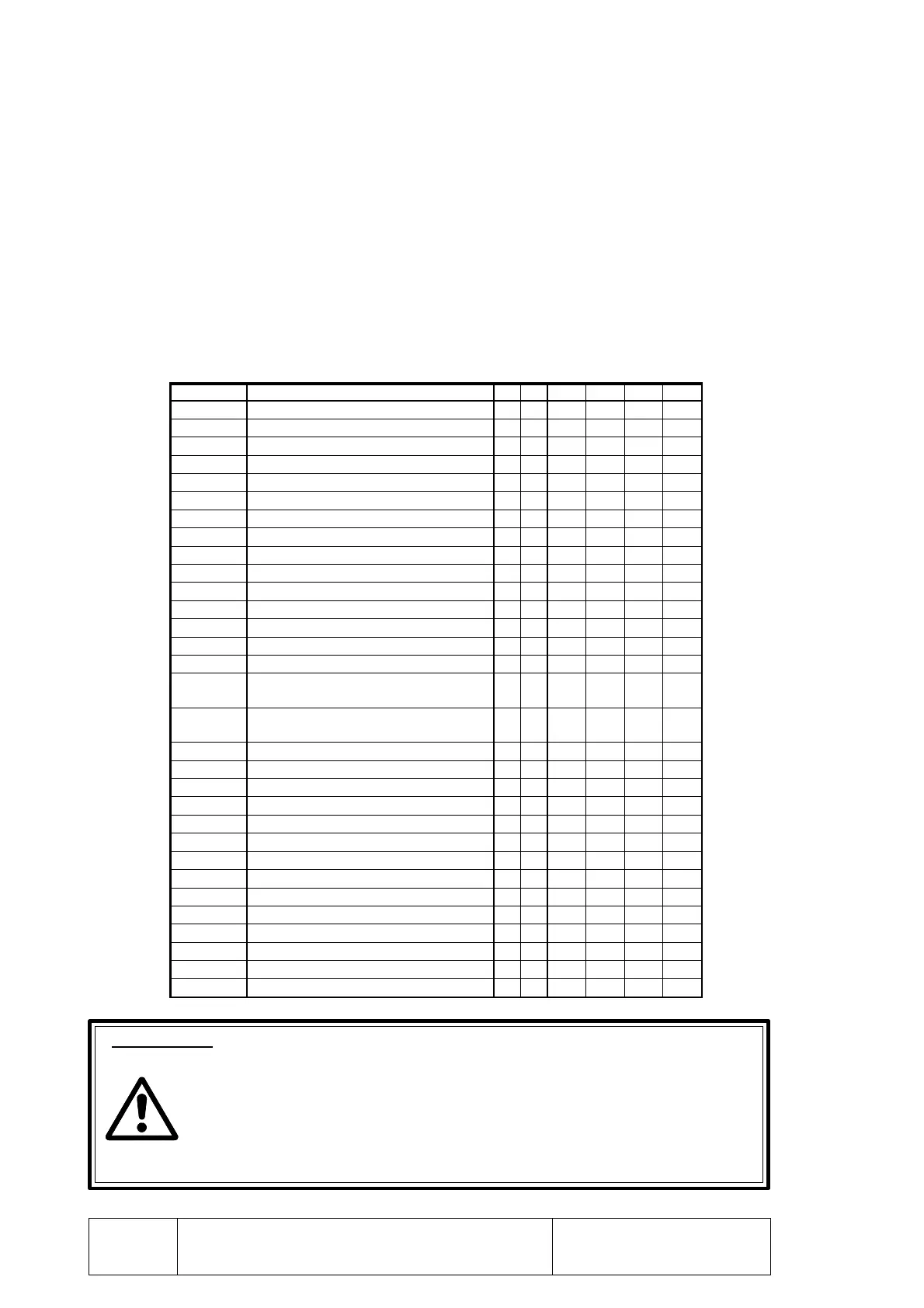

Function Description M D 101 101S 102 102S

G00 Rapid positioning * * * * * *

G01 Linear interpolation * * * * *

G02 Clockwise circular interpolation * * *

G03 Counter-clockwise circular interpolation * * *

G04 Dwell * * * *

G05 Round corner * * * * *

G07 Square corner * * * * * *

G25 Unconditional jump * * * *

G26 Jump if zero * * *

G27 Jump if not zero * * *

G28 Jump if less than zero * * *

G29 Jump if equal or greater than zero * * *

G33 Synchronization * *

G34 Axis X as infinite slave of another axis. * *

G45 Increment parts counter * * * *

G47

Feedback pulse inhibit

Open the position loop of the axes.

* * * *

G48

Cancel function G47

Close the position loop of the axes.

* * * * *

G51 to G60 Load zero offsets * * *

G60 Load the dimensions of the punch. * * * * *

G61 F not affected by "P18" * * * * *

G62 Cancel function G61 * * * * * *

G70 Inch programming * * * * * *

G71 Metric programming * * * * * *

G74 Home search * * * *

G75 Probing * * *

G81 Batch programming * *

G84, G80 Rigid tapping *

G90 Absolute programming * * * * * *

G91 Incremental programming * * * * * *

G92 Coordinate preset * * * *

G93 Modify acceleration ramp * * * *

Loading...

Loading...