N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

Page 19 of 50

CNC 8055 / CNC 8055i

Improvements in

high speed

machining

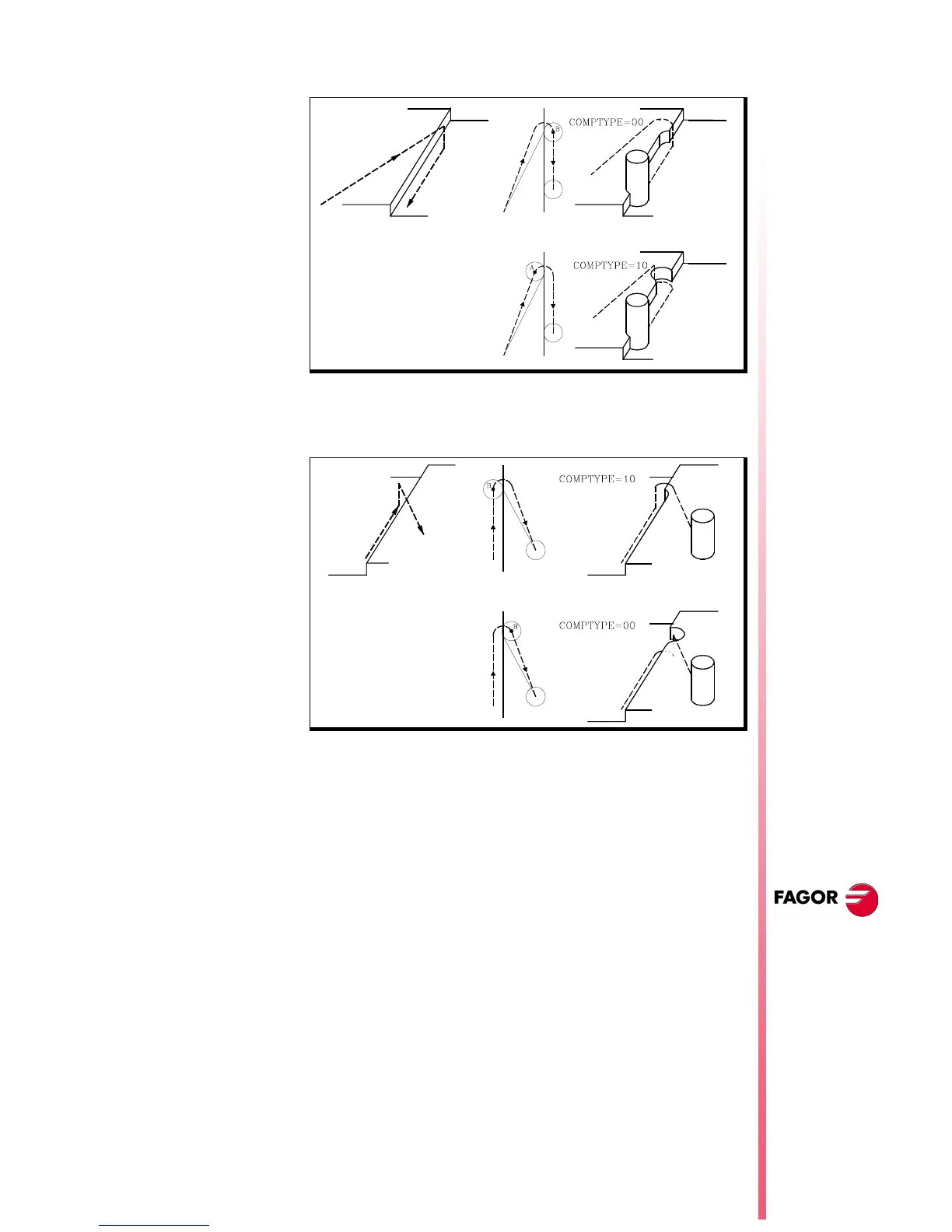

executed in the upper plane and therefore together with the first

block “COMPTYPE=00”.

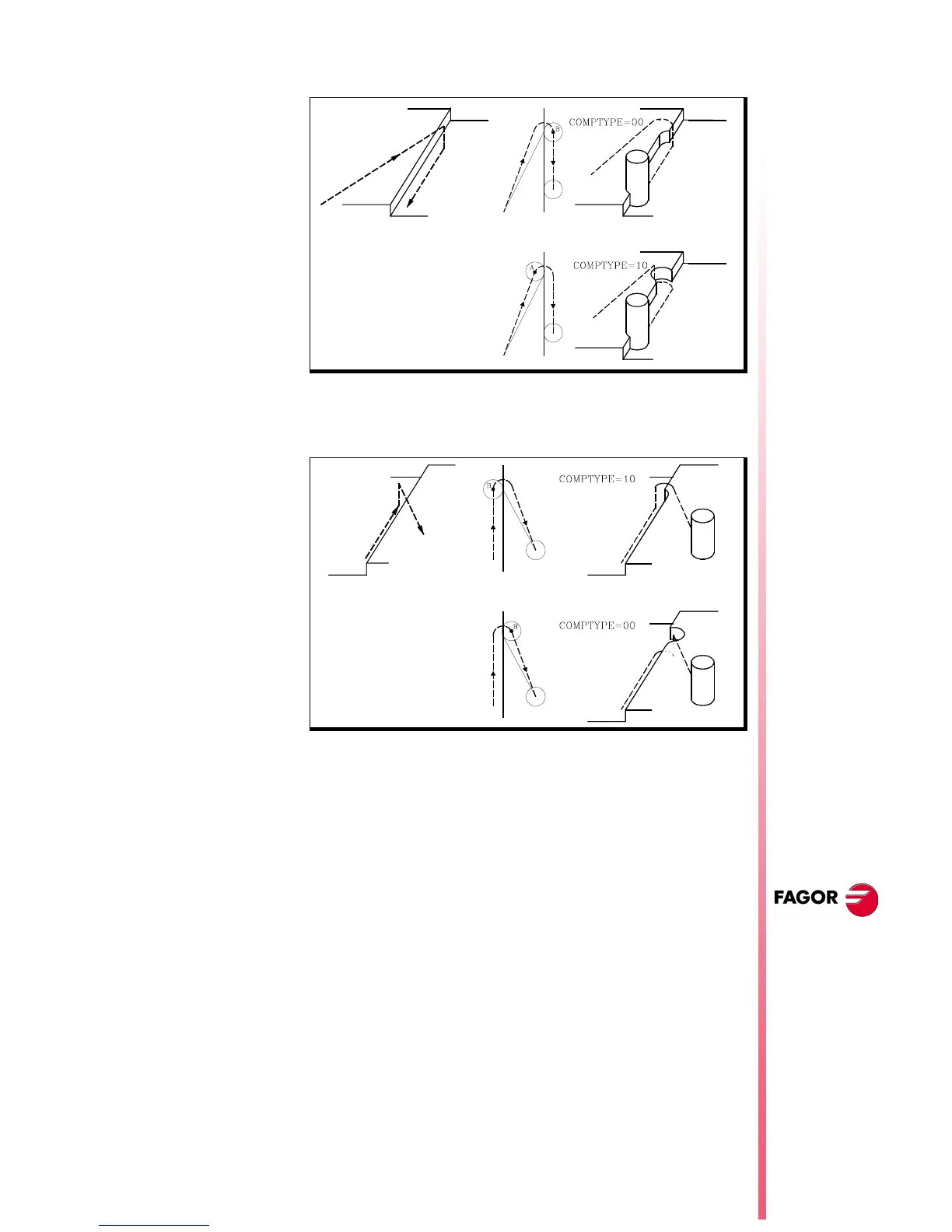

At the end of the compensation, the tool should withdraw from the

part without penetrating into it. The additional block must be

executed in the upper plane and therefore together with the second

block “COMPTYPE=10”.

29 Improvements in high speed machining

The number of blocks analyzed in advance (look-ahead) has been

increased. From 50 blocks to 75.

The extreme cases have been improved, such as small blocks (of a

few microns) in order to machine faster and more smoothly.

Jerk control can now be applied in Look-ahead, g.m.p. “JERKACT

(P160) and TLOOK (P161)”.

Using Jerk in Look-ahead, a trapezoidal acceleration profile is

applied with a ramp slope equivalent to the maximum jerk of the axis.

The maximum jerk depends on the value assigned to a.m.p.

“JERKLIM (P67)” of that axis and of the axes involved in the

programmed path.

JERKACT (P160)

This parameter has 16 bits counted from left to right.

Bit 16 indicates whether to apply Jerk control in Look-ahead or not.

(0) Not applied.

Loading...

Loading...