N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

Page 39 of 50

CNC 8055 / CNC 8055i

MC model. Tool

measurement and

calibration

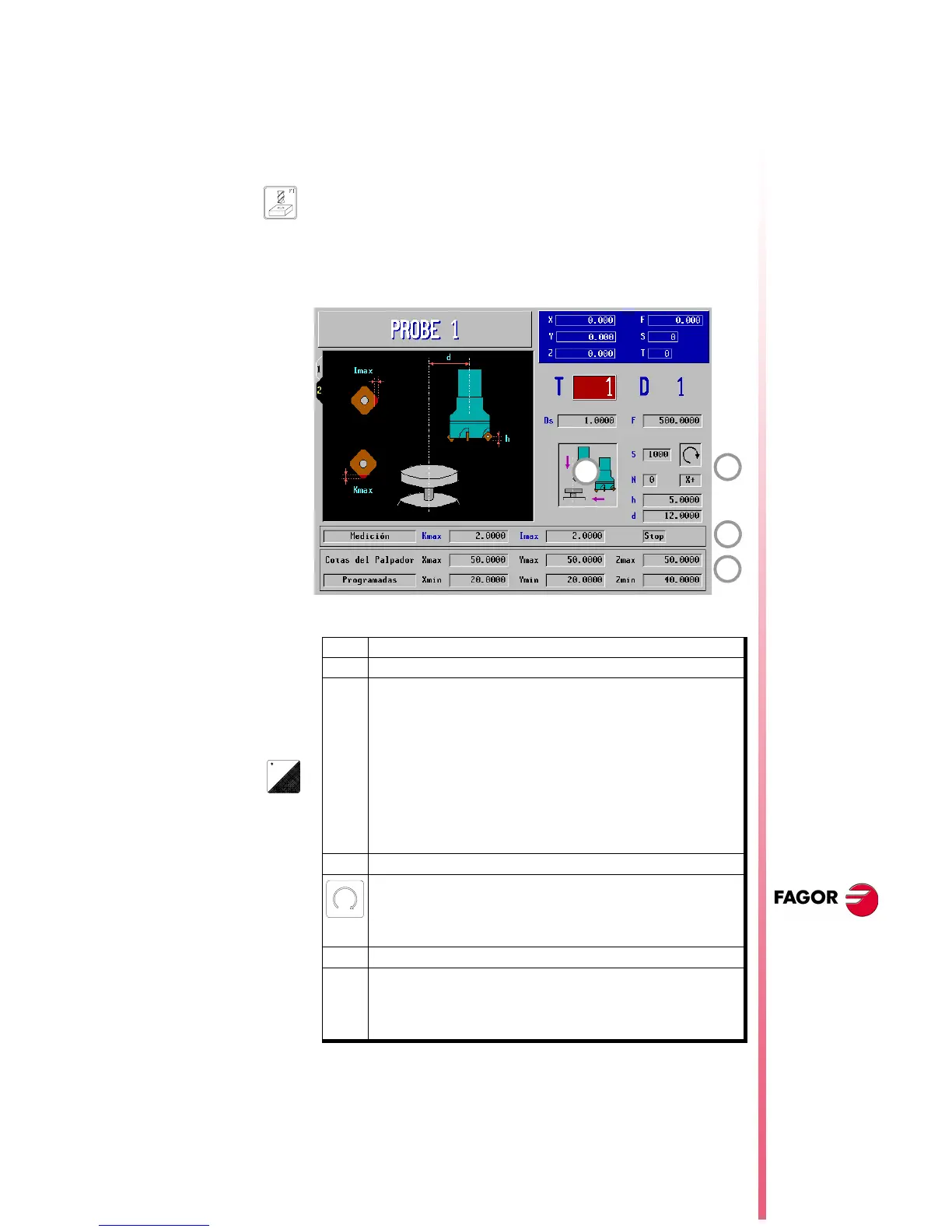

42 MC model. Tool measurement and calibration

Available with the "Canned cycles with Probe" option and if the

parameters that define the tabletop probe position g.m.p. PRBXMIN

(P40), PRBXMAX (P41), PRBYMIN (P42), PRBYMAX (P43),

PRBZMIN (P44) and PRBZMAX (P45) have been defined.

To access this mode, press the [F1] key. The first level corresponds

to "Tool calibration" and the second level to "Tool measurement and

calibration with a probe".

The screen for "Tool measurement and calibration with a probe" may

be saved as part of a part-program (PPROG) and shows the

following information:

In zone (1) the following may be defined:

Ds Safety distance, for the probe approach.

F Probing feedrate.

(A) Type of calibration or measurement.

•

Calibrate the length or measure the tool length wear

along its shaft.

•

Calibrate the length or measure the tool length wear on its

tip.

•

Calibrate the radius or measure the radius wear of a tool.

•

Calibrate the radius and the length or measure the radius

and length wear of a tool.

To select the desired one, position over the desired icon and

press the (a) key.

S Tool turning speed.

Tool turning direction. Select the direction opposite to the

cutting direction.

To select the desired one, position over the desired icon and

press the (a) key.

N Number of cutting edges of the tool to be measured.

X+ In radius calibration and measurement, it indicates the

side of the probe to be used: (X+) (X-) (Y+) (Y-).

To select the desired one, position over the desired field and

press the (a) key.

(F1)

1

2

3

A

(a)

Loading...

Loading...