18

La Lw Ln Lw La

Wa

Wn

Ww

Wmax

Wa

Lmax

!

Bandsaw

FB 540/640/740/840/940

The machine can either be lifted and transported with a

fork carriage or with a crane sling with a hoisting power

of at least 2000 kg.

The following points are important for a correct and ef-

ficient machine installation:

• Install the machine in such a way as not to amplify

the vibrations and machine noise.

• Ensure that workplace lighting is adequate.

• If the machine is to be installed between other ma-

chines, leave at least 80 cm distance in-between, in

order to avoid collisions when cutting large work-

pieces and to allow the use of equipment such as roll

supports and additional tables.

• There are 4 threaded holes located in the base plate

of the machine where the levelling screws supplied

with the machine can be screwed into.

6.2.1 Safety instructions

Fig. 5: Pallet jack

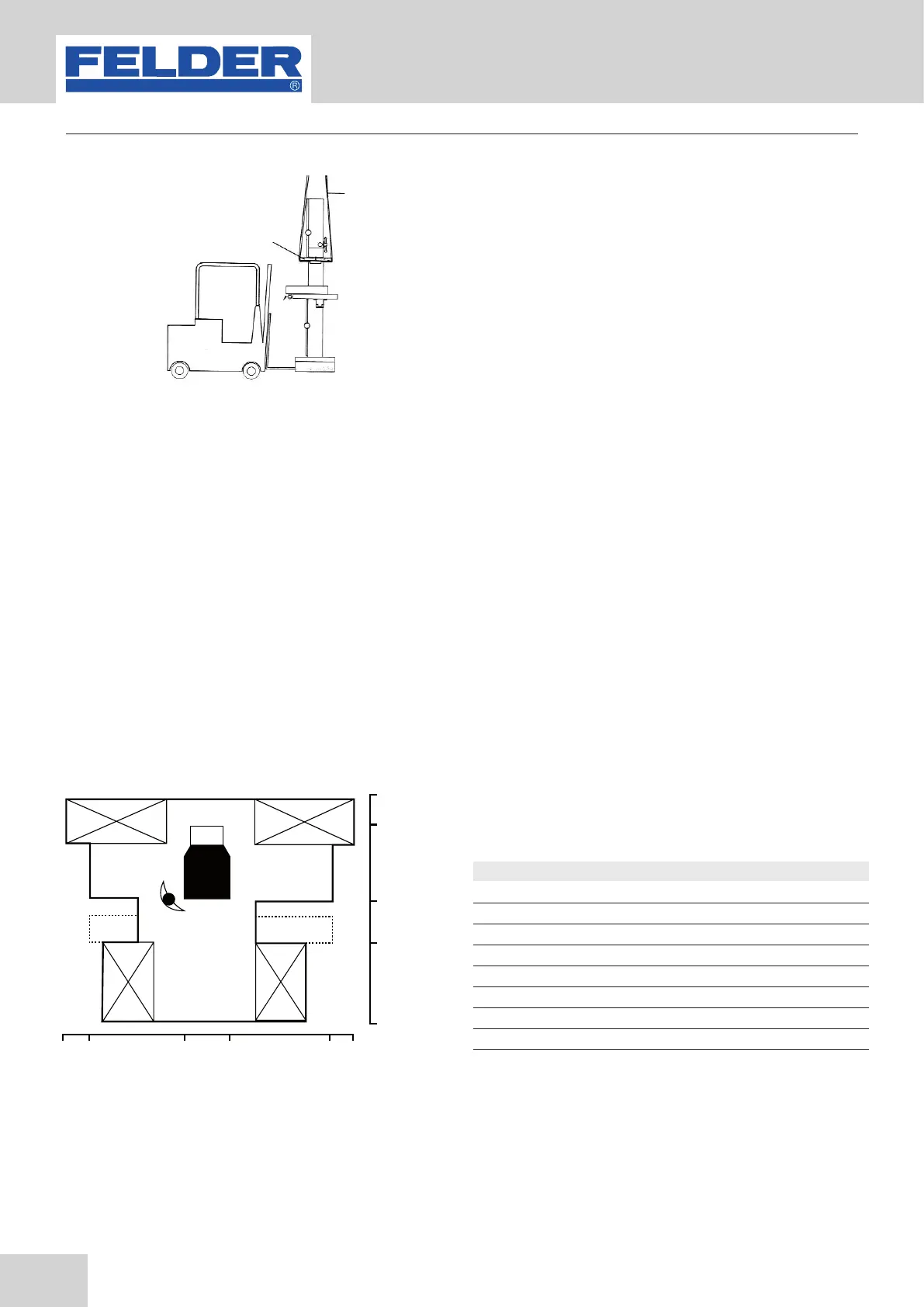

Fig. 6: Diagram

Setup and installation

Scale 1:100

Lmax : Max. length

Wmax : Max. width

Ln: Machine length

Wn : Machine width

Lw : Working length

Ww : Working width

La: Auxiliary support area length

Wa : Auxiliary support area width

• In the base plate are also 4 additional bores, which

are to screw the machine to the floor. However, do

not overtighten the mounting screws, as this will as a

result, increase vibrations. It is also recommended to

lay vibration dampening materials between the floor

and the machine.

Look at the diagram in Fig.6 before setting up the ma-

chine.

!Wood 80x40x360

Loading...

Loading...