14

!

"

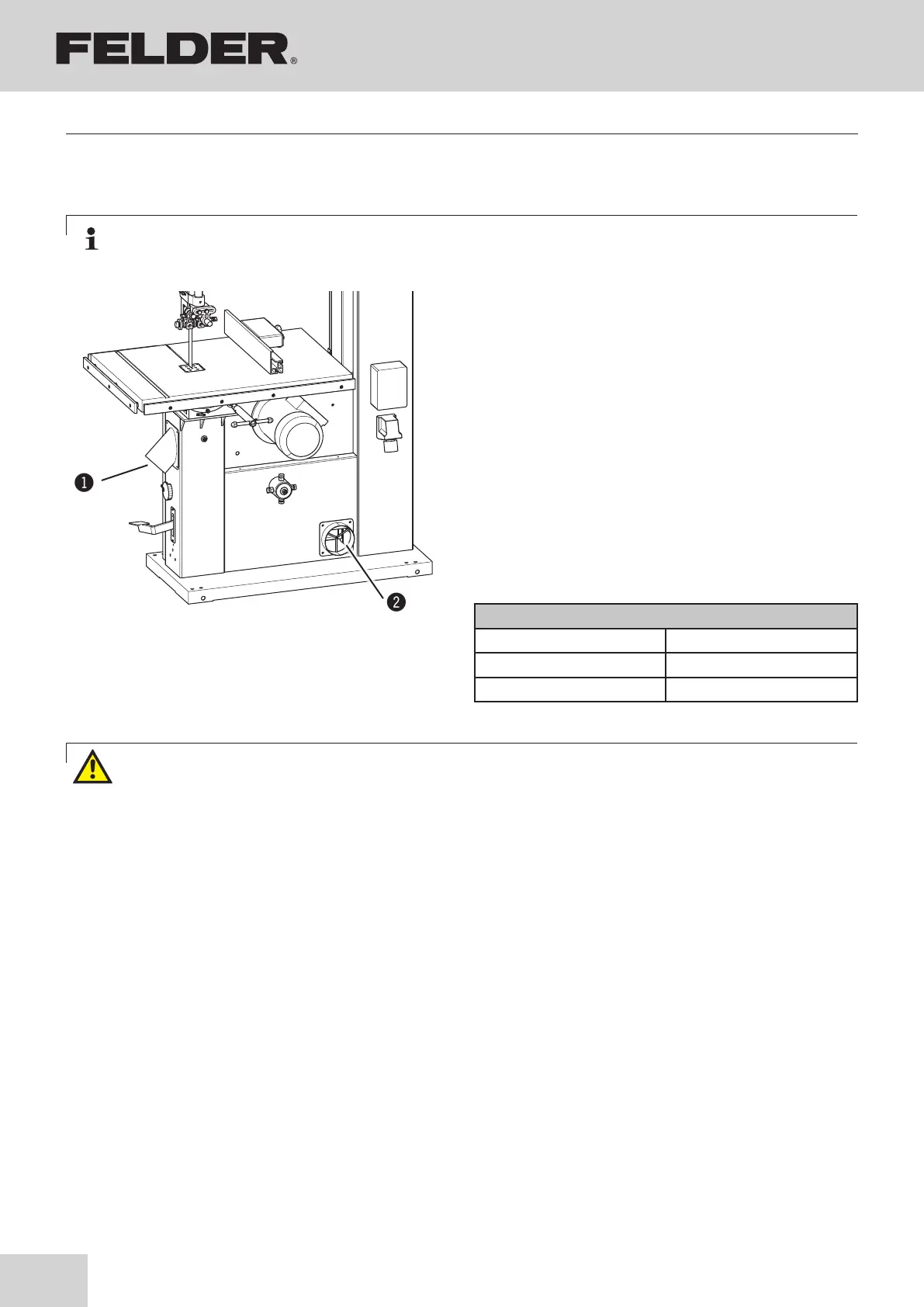

Bandsaw

FB 510/610/710 & FB 710 c-tech

Vacuum connector

Diameter 120 mm

Volume flow 814 m³/h (at 20 m/s)

Vacuum 917 Pa

4.5 Dust extractors

The machine has to be connected to a dust extractor. The

connection values and the position of the connection port

are shown on the picture.

The air speed at the connection point has to be a mini-

mum of 20 m/s for materials with a humidity less than

12 %.

The air speed should be increased to 25–28 m/s to ex-

tract dust from more humid materials (over 12 %).

Only flame resistant vacuum hoses can be used, conform-

ing to DIN 4102 B1 and any other safety regulations in

effect.

Fig. 4-1: Connection ports

!Connection ports 120 mm

"Connection ports 120 mm

Specifications

Warning! Risk of injury! The dust extraction hose must be non-flammable and must not conduct electricity! For

this reason, only use genuine FELDER dust extraction hoses!

Note: As a rule, all units must be vacuumed during use. A time delayed socket is available as an accesso-

ry.

• In addition, the vacuum performance must be sufficient

to achieve the required negative pressures and an air

speed of 20 m/s at the connector. (see “Technical

data”)

• Check the air speed before putting the machine into

operation for the first time and after essential changes.

• The dust extractor setup must be controlled before the

machine is put into operation for the first time. Check for

obvious defects on a daily basis and the efficiency on a

monthly basis.

• The dust extractor must be connected to the machine

in such a manner that it runs in unison with the

machine.

• The dust extraction hoses must be electrically conduc-

tive and grounded to prevent electrostatic

build up.

• Use dust extractors with reduced dust emission to clean

dust from the machine.

Loading...

Loading...