7

Speed regulation:

Using the electronic speed control (1.1) the motor

speed can be continuously adjusted from 9 500 and

23 000 rpm.

The table aside offers a guide to the correct elec-

tronic setting for various materials. The settings

are naturally infi nitely variable.

Constant speed:

The selected motor speed is electronically main-

tained to a constant level. By this means a uniform

cutting speed is achieved.

Temperature protection:

Extreme overloading during continuous use leads

to the motor overheating. To protect against

overheating (burnout of the motor) an electronic

temperature monitor is installed. Before a critical

motor temperature is reached, the safety electron-

ics switch the motor off. After a cooling down time

of about 3 to 5 minutes, the machine is ready for

operation again and can be fully loaded. The cool-

ing down time can be reduced considerably if the

machine is allowed to idle.

Tool settings

Always disconnect the plug from the

power supply before making any adjustments to the

router or installing or removing any accessory!

Chips extraction

A connection for extracting dust and chips (1.6) is

a standard feature on the routers.

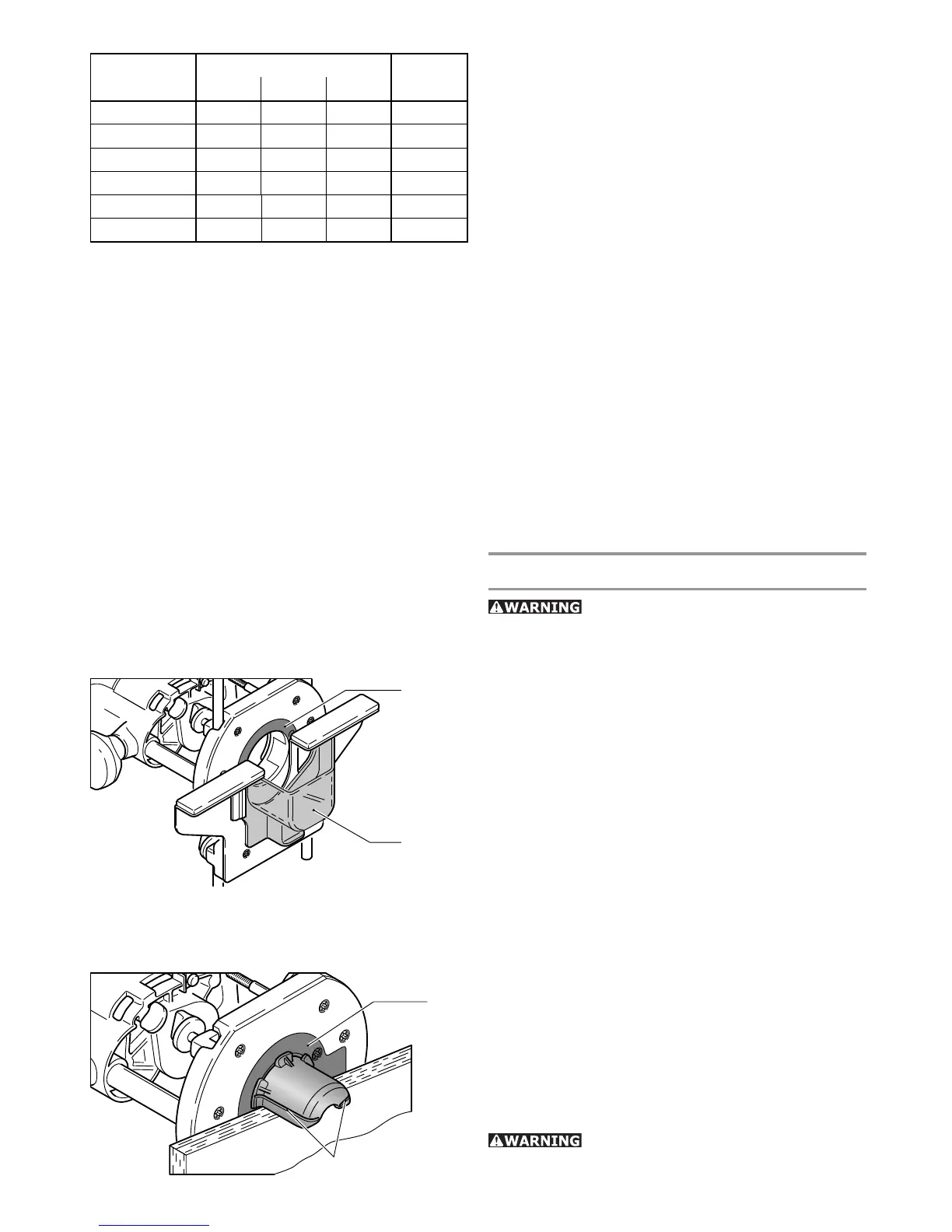

At the same time a chip guard (4.1) on the parallel

guide (accessory) prevents fl ying chips. With edge

routing, the best extraction effect is obtained with

the extractor hood AH-OF (accessory).

KSF-OF chip catcher

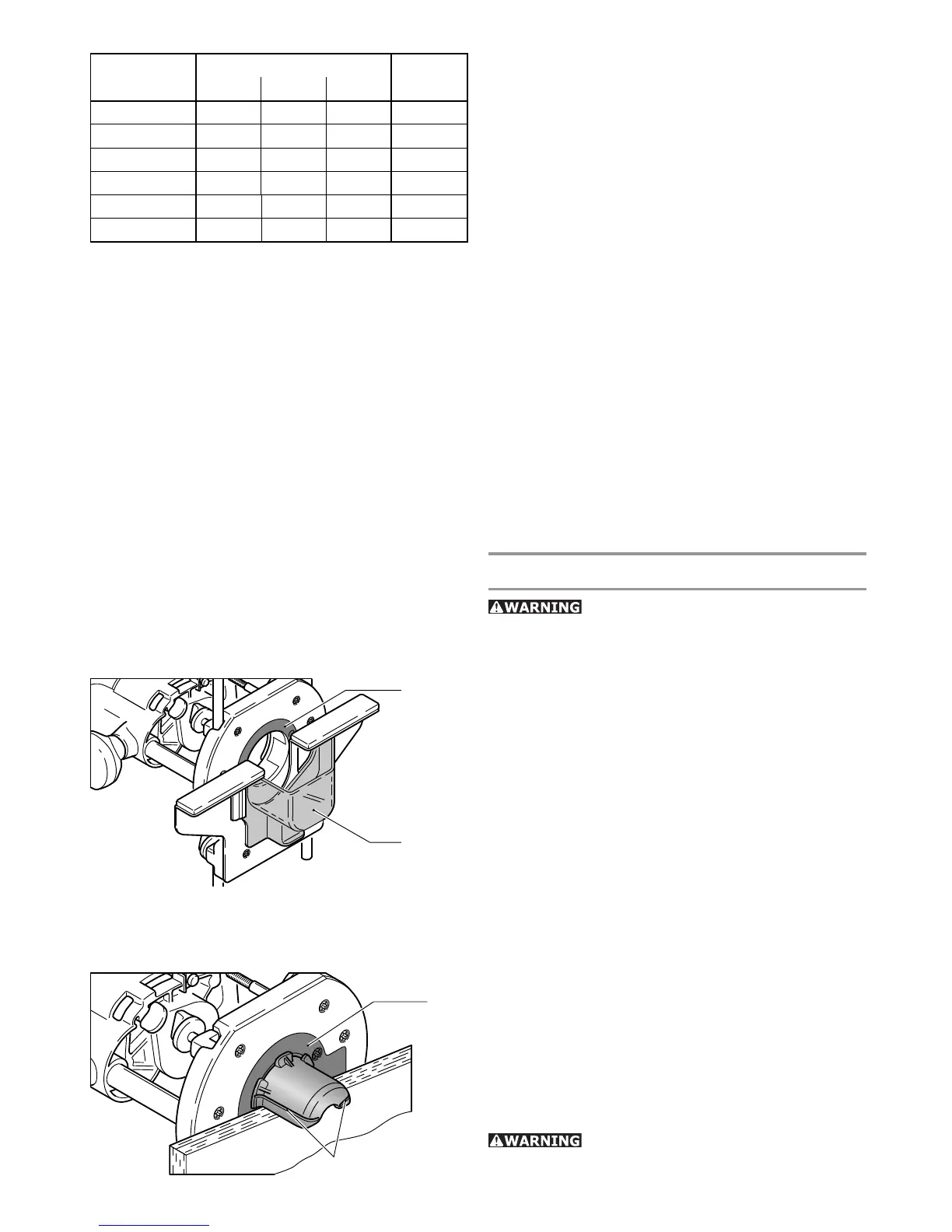

Using the KSF-OF chip catcher (sometimes in-

cluded in the scope of delivery), the effi ciency of the

extraction can be increased when routing edges.

Fasten the KSF-OF chip catcher (5.1) to the platen

instead of the cover ring (4.2) from below.

The hood can be cut off along the grooves (5.2) us-

ing a hacksaw and can thus be reduced in size. The

chip catcher can then be used for interior radiuses

up to a minimum radius of 40 mm.

Milling cutters

Do not exceed the maximum speed

specifi ed on the tool and/or keep to the speed

4.1

4.2

5.1

5.2

Material

Cutter diameter [mm] Cutter

material

3-14 15-25 26-35

Hard wood 6-4 5-3 3-1 HW/HSS

Soft wood 6-5 6-3 4-1 HSS/HW

Panels 6-5 6-3 4-2 HW

Plastic 6-4 5-3 2-1 HW

Aluminium 3-1 2-1 1 HSS/HW

Plasterboard 2-1 1 1 HW

Loading...

Loading...