8

range. Cracked or distorted cutters must not be

used.

We recommend that milling cutters with diam-

eters over 30 mm should not be used with this

machine.

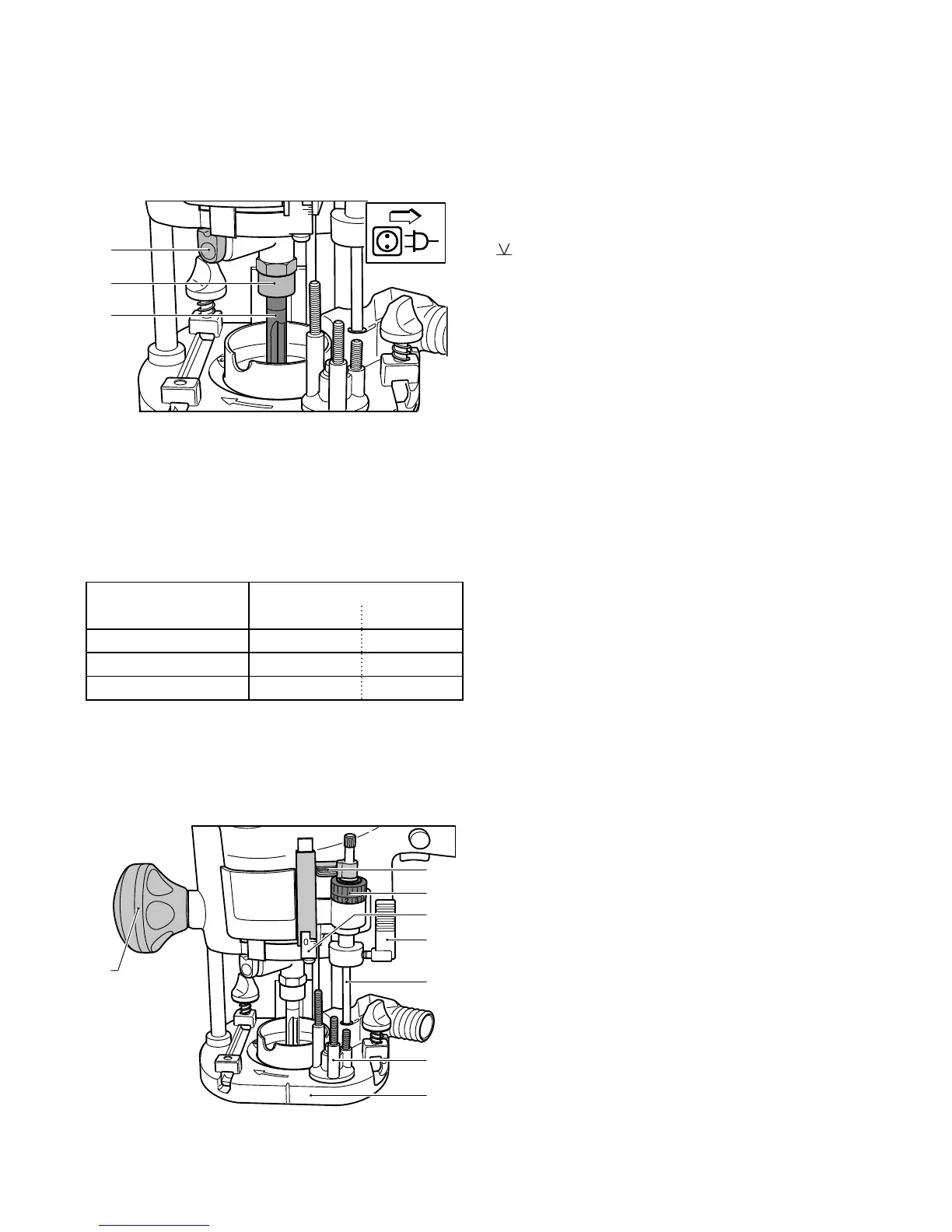

Inserting the tool

- Insert the router (6.3) into the open clamping col-

let as far as possible, but at least up to the mark

on the router shank.

- Turn the spindle until the spindle stop (6.1) catches

when pressed and the spindle is locked in place.

- Tighten the collet nut (6.2) with a 19 mm open-end

spanner.

Removing the tool

- Turn the spindle until the spindle stop (6.1) catches

when pressed and the spindle is locked in place.

- Loosen the collet nut (6.2) using a 19 mm open-

ended spanner until a resistance is felt. Overcome

this resistance by turning the open-ended span-

ner even further.

- Remove the cutter.

Clamping collet changing

- Fully unscrew the collet nut (6.2) and remove from

spindle together with the clamping collet.

- Only insert a new clamping collet in the spindle

when the nut is attached and engaged, then

tighten the nut slightly. Do not tighten the collet

nut until a milling cutter has been fi tted!

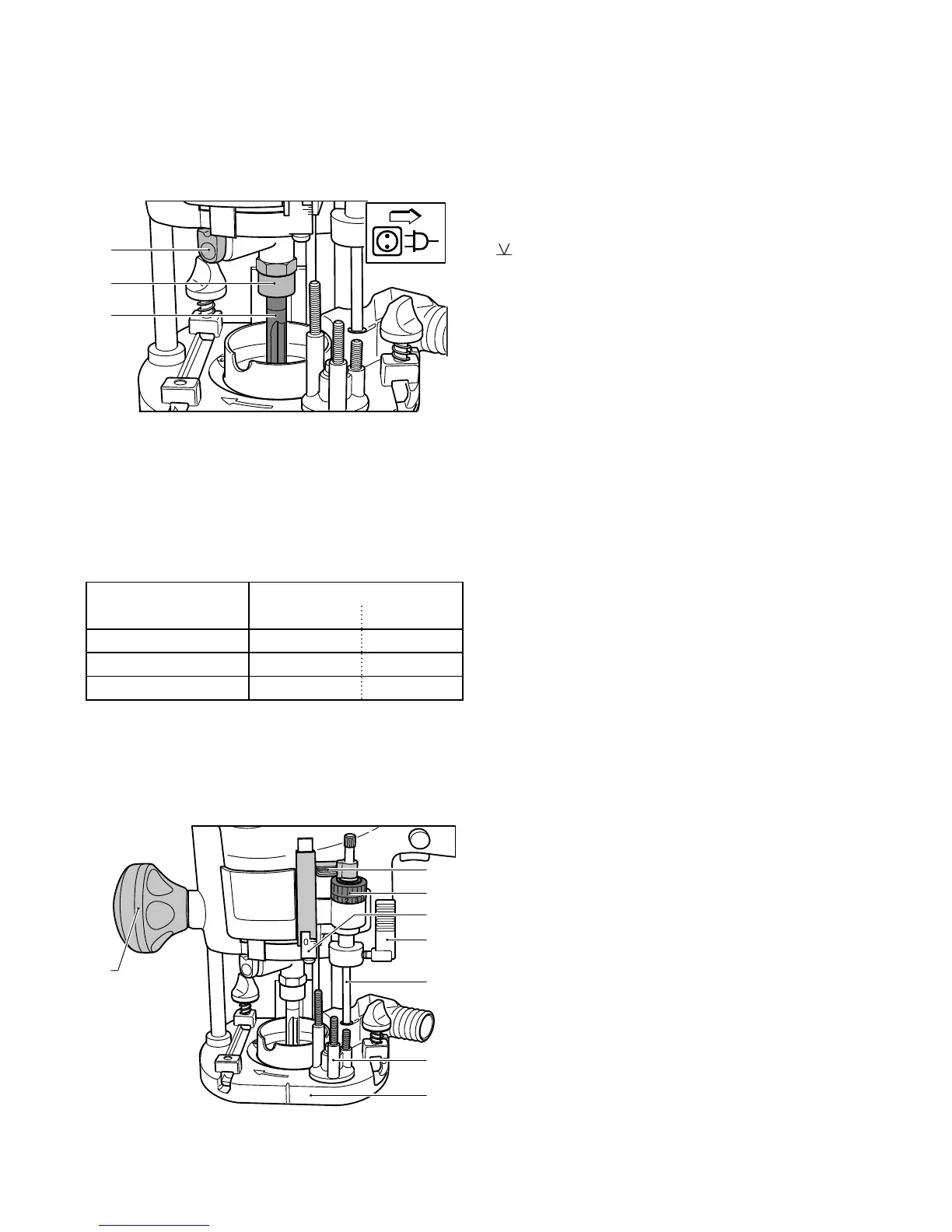

Adjusting the milling depth

The milling depth is adjusted in three stages:

a) Setting the zero point

- Open the clamping lever (7.4) so that the stop

cylinder (7.5) can be moved freely.

- Place the router with router table (7.7) onto a

smooth surface. Open the rotary knob (7.8) and

press the machine down until the milling cutter

rests on the base. Clamp the machine tight in this

position with the rotary knob (7.5).

- Press the stop cylinder against one of the three

sensing stops of the pivoted turret stop (7.6).

- The individual height of each sensing stop can be

adjusted with a screwdriver.

- Push the pointer (7.1) down so that it shows 0 mm

on the scale (7.3).

6.2

6.3

6.1

Cutter shank Clamping collet

Ø Order-No.

Ø 6 mm 6 mm 488 764

Ø 6,35 mm (1/4") 6,35 mm 488 765

Ø 8 mm 8 mm 488 763

7.8

7.3

7.2

7.1

7.4

7.5

7.6

7.7

Loading...

Loading...