4140

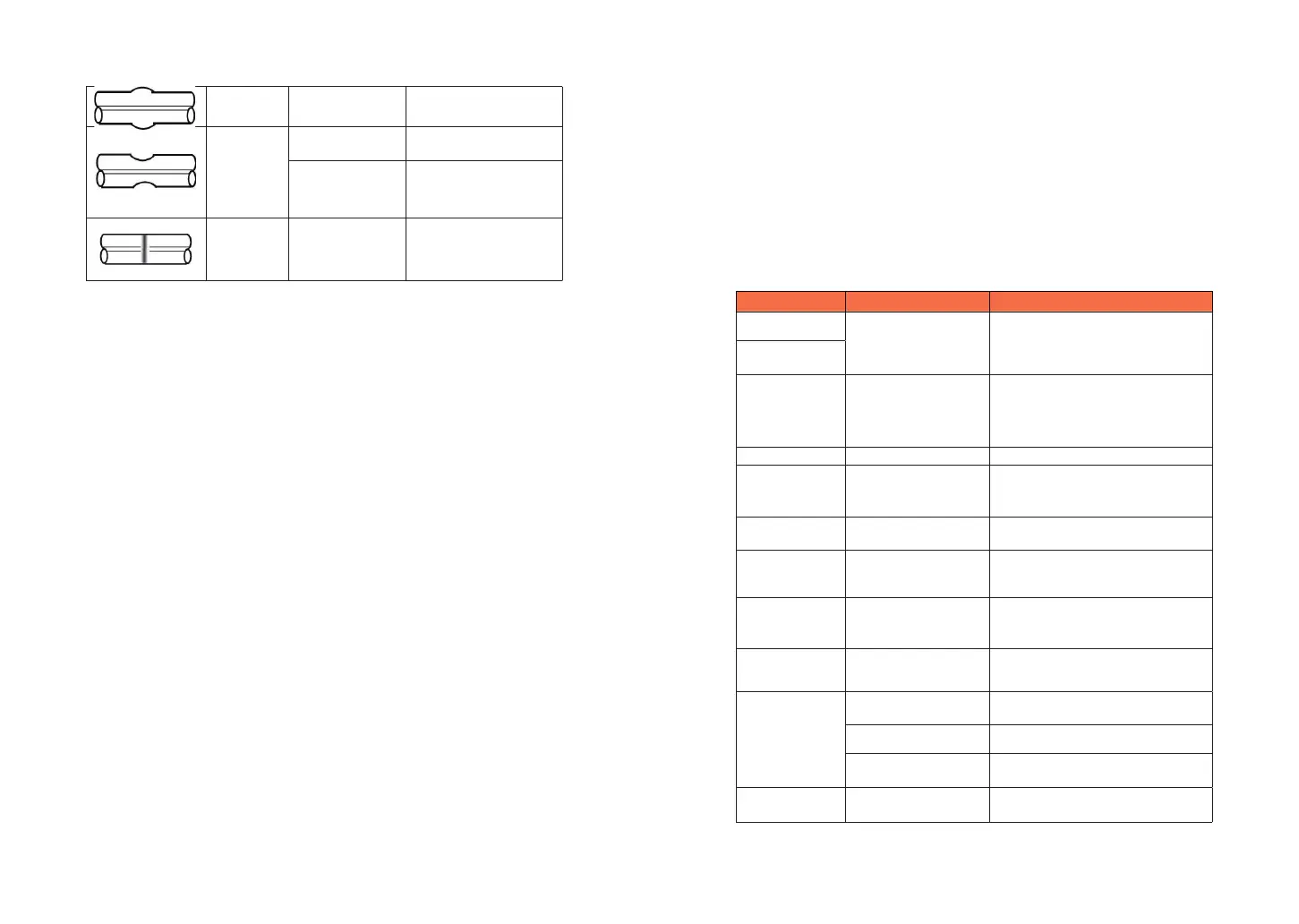

Error Message Cause Solution

Left Fiber Place

Error

The ber end-face is placed

on the electrode centerline.

Press RESET button, and reload the bers

to make sure that ber end face is placed

between V-groove and the centerline of

electrodes.

Right Fiber Place

Error

Press Motor Distance

Over Limit

The ber is not set correctly

at the bottom of the

V-groove, which results in

that the ber osets beyond

motor formation range.

Press the “RESET” button; correctly re-

position the ber at the bottom of the

V-groove.

Press Motor Error Motor might be damaged. Consult your nearest sales agent.

Search Fiber End

face Failed

The ber is not set

correctly at the bottom of

the V-groove.

Press the “RESET” button; correctly re-

position the ber at the bottom of the

V-groove.

Arc Failure

Arc discharge does not

occur.

Conrm the electrodes are in proper

position; Replace the electrodes.

Align Motor Distance

Over Limit

The ber is not set correctly

at the bottom of the

V-groove.

Press the “RESET” button; correctly re-

position the ber at the bottom of the

V-groove.

Search Fiber Clad

Failed

The ber is not set

correctly at the bottom of

the V-groove.

Press the “RESET” button; correctly re-

position the ber at the bottom of the

V-groove.

Fiber Border

Position Wrong

There’s dust or dirt on the

ber surface

Prepare the ber (stripping, cleaning, and

cleaving) again; clean the lens; redo [Dust

Check]

Unknown Fiber Type

There’s dust or dirt on the

ber surface

Prepare the ber (stripping,

cleaning, and cleaving) again.

Dierent ber types on two

sides.

Use an appropriate splice mode other than

AUTO splice mode to re -splice.

Non-standard optical bers

AUTO splice mode can only detect the

standard SM, MM, NZ bers.

Fiber Clad Over

Limit

Fiber edge is not located in

the camera range.

Adjust the ber position and perform “motor

calibration” .

Appendix B

During the splice operating process, if the error messages are shown on the screen,

please follow the solution precisely as shown in the list below. If it is not possible to

solve the problem, the splicer may require service by a qualied service center. In

this case, please contact sales agents.

Note:

A vertical line sometimes appears at the splice point when MM bers or dissimilar

bers (dierent diameters) are spliced. We call it as “Splicing line”. This does not

aect splice quality (such as splice loss and tensile strength).

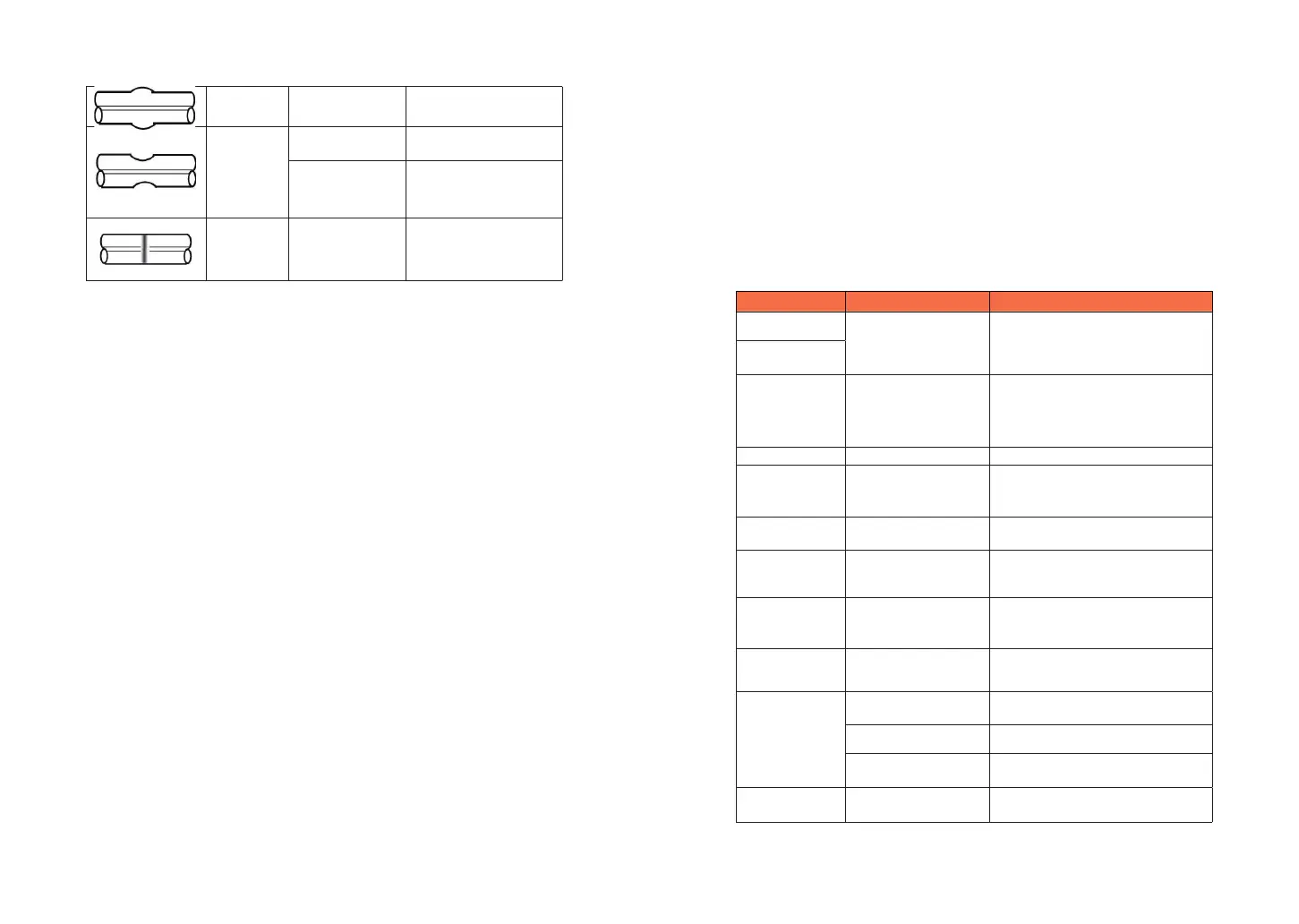

Fat

Fiber stung too

much

Decrease [Overlap] and

Perform [Arc Calibration].

Thin

Arc power not

adequate

Perform [Arc Calibration].

Some arc

parameters not

adequate

Adjust [Pre-fuse Power],

[Pre-fuse Time] or

[Overlap].

Splicing line

Some arc

parameters not

adequate

Adjust [Pre-fuse Power],

[Pre-fuse Time] or

[Overlap]

High Splice loss: Cause and solutions

Loading...

Loading...