4342

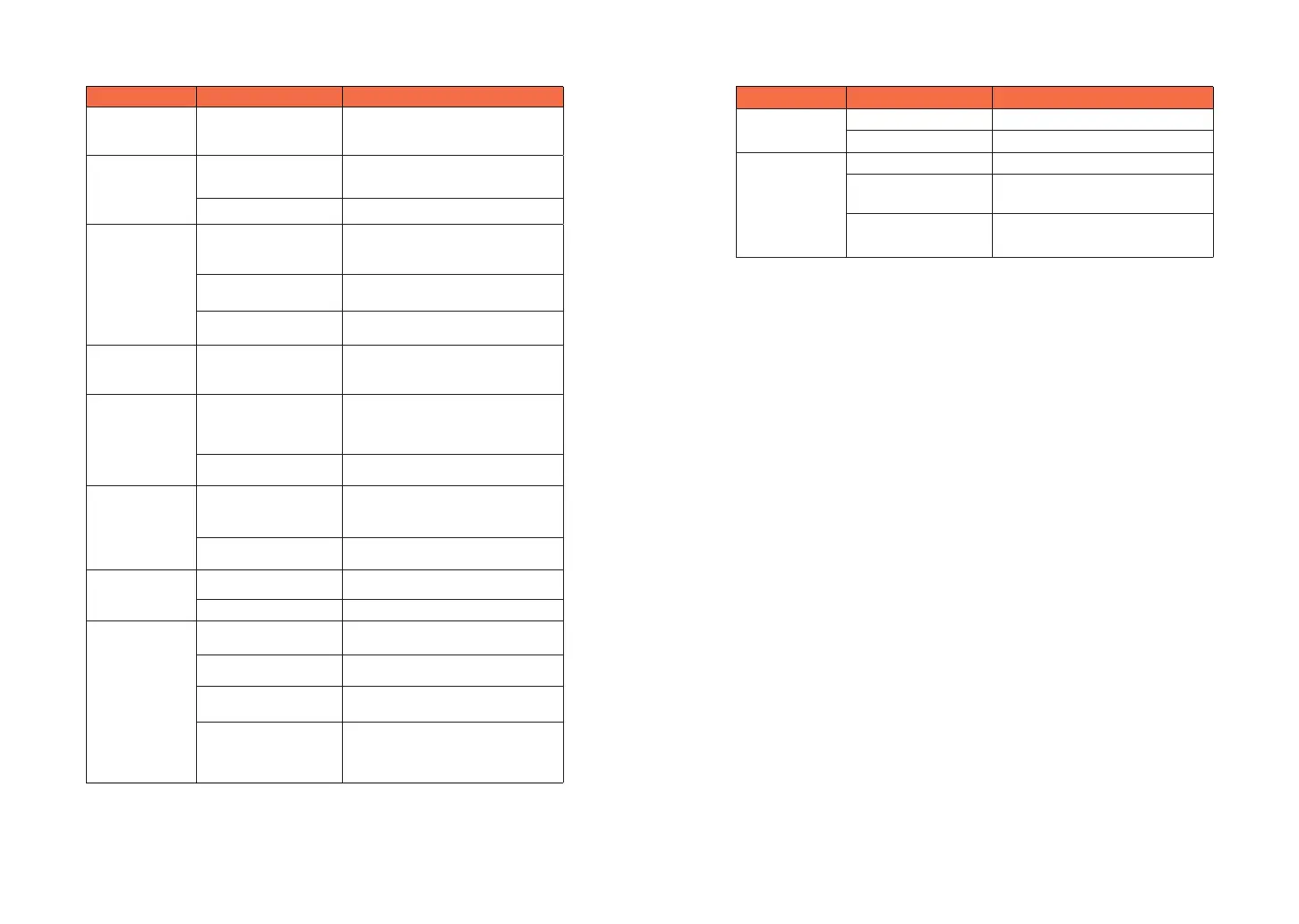

Error Message Cause Solution

Focus Motor Home

position Error

Shock occurred to the

splicer during the splicing

process.

Carry out “motor calibration”. If the

problem still exists, please contact sales

agent.

Fiber End face Gap

Wrong

Too much [Overlap] setting Adjust [Overlap] parameter setting.

The motor is not calibrated Perform [Motor Calibration].

Focus Motor

Distance Over Limit

The ber is misplaced.

Press the “RESET” button; re-position

the ber correctly at the bottom of the

V-groove.

There’s dust or dirt on the

ber surface

Prepare the ber (stripping,

Cleaning and cleaving) again.

There’s dust or dirt on the

lenses.

Execute the [Dust Check] after cleaning

the lenses and mirrors.

Fiber Mismatch,

Continue?

Dierent ber types on two

sides.

It may result in large splice loss if you

continue to splice, Please use the proper

splice mode corresponding to the bers.

Cleave Angle Over

Limit

Bad ber end-face

Check the condition of the ber cleaver.

If the blade is worn, rotate the blade to a

new position or change a new one, and

then re-prepare the bers.

[Cleave Angle Limit] is set

too low.

Increase the “Cleave Angle Limit” to an

adequate limit. (standard value: 3.0°).

Core Angle Over

Limit

[Core Angle Limit] is set

too low.

Increase the “Core Angle Limit” to an

adequate limit.

(standard value: 1.0°).

Dust or dirt is on the

V-groove or ber holders.

Clean the V-groove and the ber holders.

Prepare and reload the ber again.

Fiber Axis Align

Failed

Too large axial oset

(>0.4μm)

Prepare the ber (stripping, cleaning, and

cleaving) again.

The motor is not calibrated Perform “Motor Calibration”.

Fiber is Dirty

There’s dust or dirt on the

ber surface

Prepare the ber (stripping,

cleaning, and cleaving) again.

Dust or dirt is on the lenses

Perform the “Dust Check” after cleaning

the lenses.

“Cleaning Arc time” is too

short

Set the “Cleaning Arc time” to 180ms

It is dicult to identify

the ber core by using the

method of core alignment to

splice.

Use MM splice mode (clad alignment) to

splice the unidentied ber core.

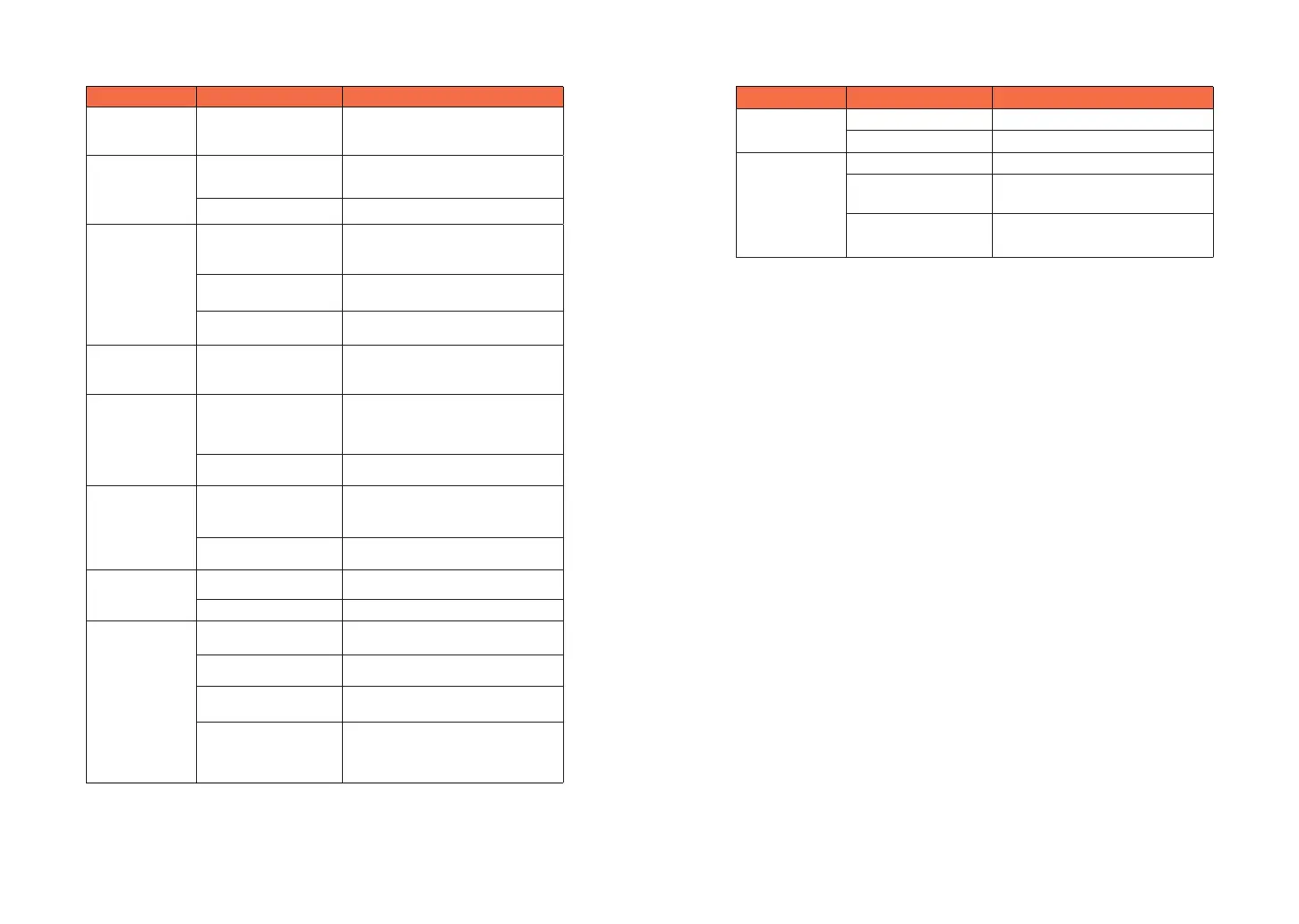

Error Message Cause Solution

Fat Splicing Point

Too much [Overlap] setting Adjust “Overlap” parameter setting.

The motor is not calibrated. Perform “Motor Calibration”.

Thin Splicing Point

Arc power is too low Perform “Arc Calibration”.

The level of pre-discharge

is set too high

Decrease pre-discharge or pre-discharge

time.

Insucient “Overlap” setting Adjust “Overlap” parameter setting

Loading...

Loading...