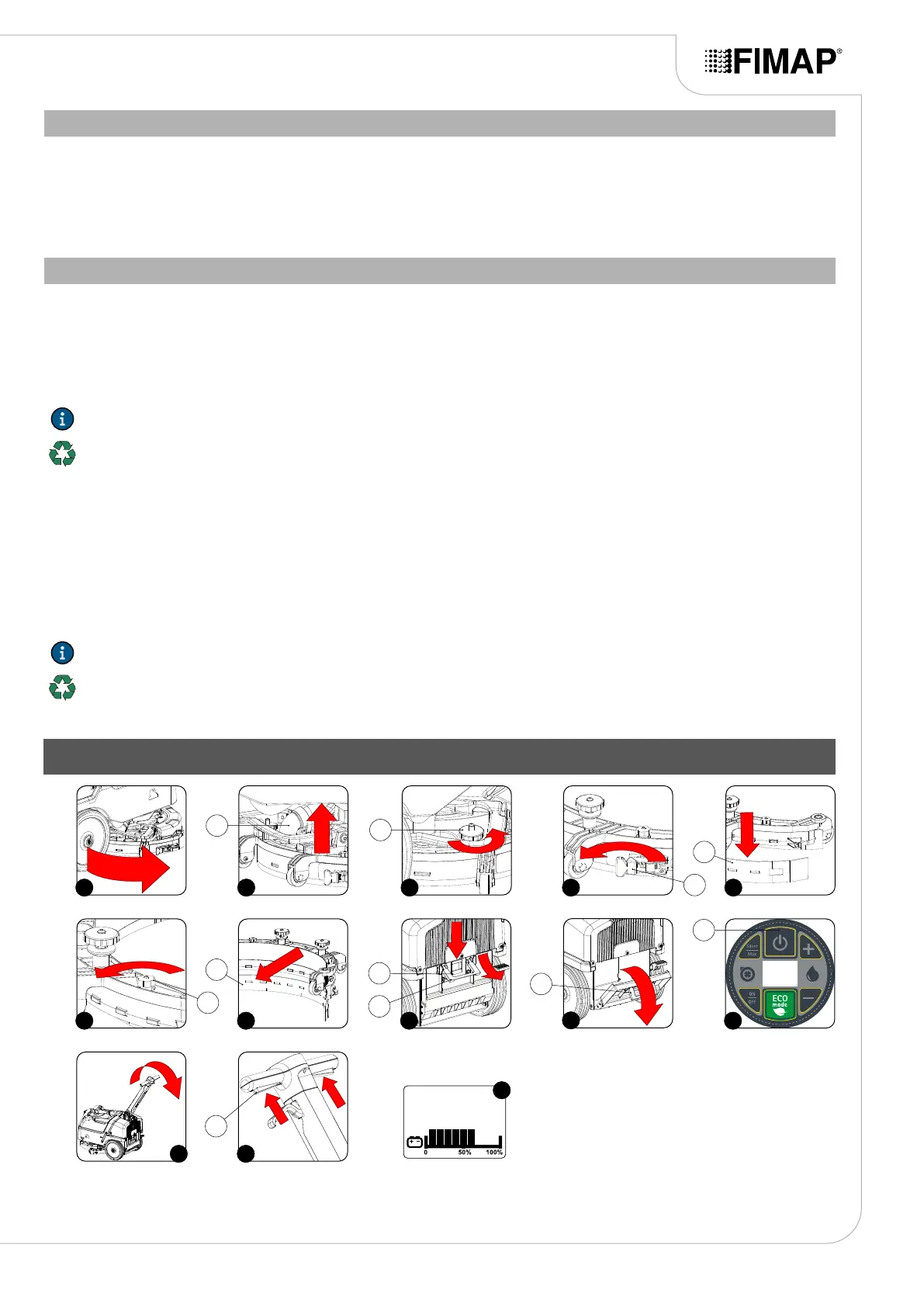

CLEANING THE VACUUM TUBE

Careful cleaning of the vacuum hose guarantees better cleaning of the oor as well as a longer vacuum motor life.

Proceed as follows to clean the vacuum hose:

1. Extract the vacuum tube (5) from the vacuum nozzle on the squeegee body (Fig.5).

2. Remove the vacuum tube (1) via the hole on the back of the recovery tank (Fig.1).

3. Rinse the inside of the vacuum hose with a jet of running water.

4. Repeat the operations in reverse order to reassemble all the parts.

CLEANING THE RECOVERY TANK

To clean the recovery tank of GL machines, proceed as follows:

1. Disconnect the suction motor tube (1) from the sleeve in the recovery tank cover (Fig.1).

2. Disconnect the squeegee tube (2) from the sleeve in the recovery tank cover (Fig.1).

3. Use the handle (3) to remove the recovery tank (Fig.2) from the machine.

4. Unscrew the dumping system cap (4) of the recovery tank (Fig.3).

5. Rinse the inside of the recovery tank under a jet of running water.

N.B.: Use a spatula or brush to eliminate any dirt that is particularly dicult to remove.

N.B.: the place designated for this operation must comply with current environmental protection regulations.

6. Repeat the operations in reverse order to reassemble all the parts.

To empty the recovery tank of GXL machines, proceed as follows:

1. Disconnect the suction motor tube (1) from the sleeve in the recovery tank cover (Fig.1).

2. Disconnect the squeegee tube (2) from the sleeve in the recovery tank cover (Fig.1).

3. Use the handle (3) to remove the recovery tank (Fig.2) from the machine.

4. Release the recovery tank drainage tube (19) (on the left-hand side of the machine) from the retainers (Fig.20).

5. Unscrew the cap and lay the drainage tube over the drain well.

6. Rinse the inside of the recovery tank under a jet of running water.

N.B.: Use a spatula or brush to eliminate any dirt that is particularly dicult to remove.

N.B.: the place designated for this operation must comply with current environmental protection regulations.

7. Repeat the operations in reverse order to reassemble all the parts.

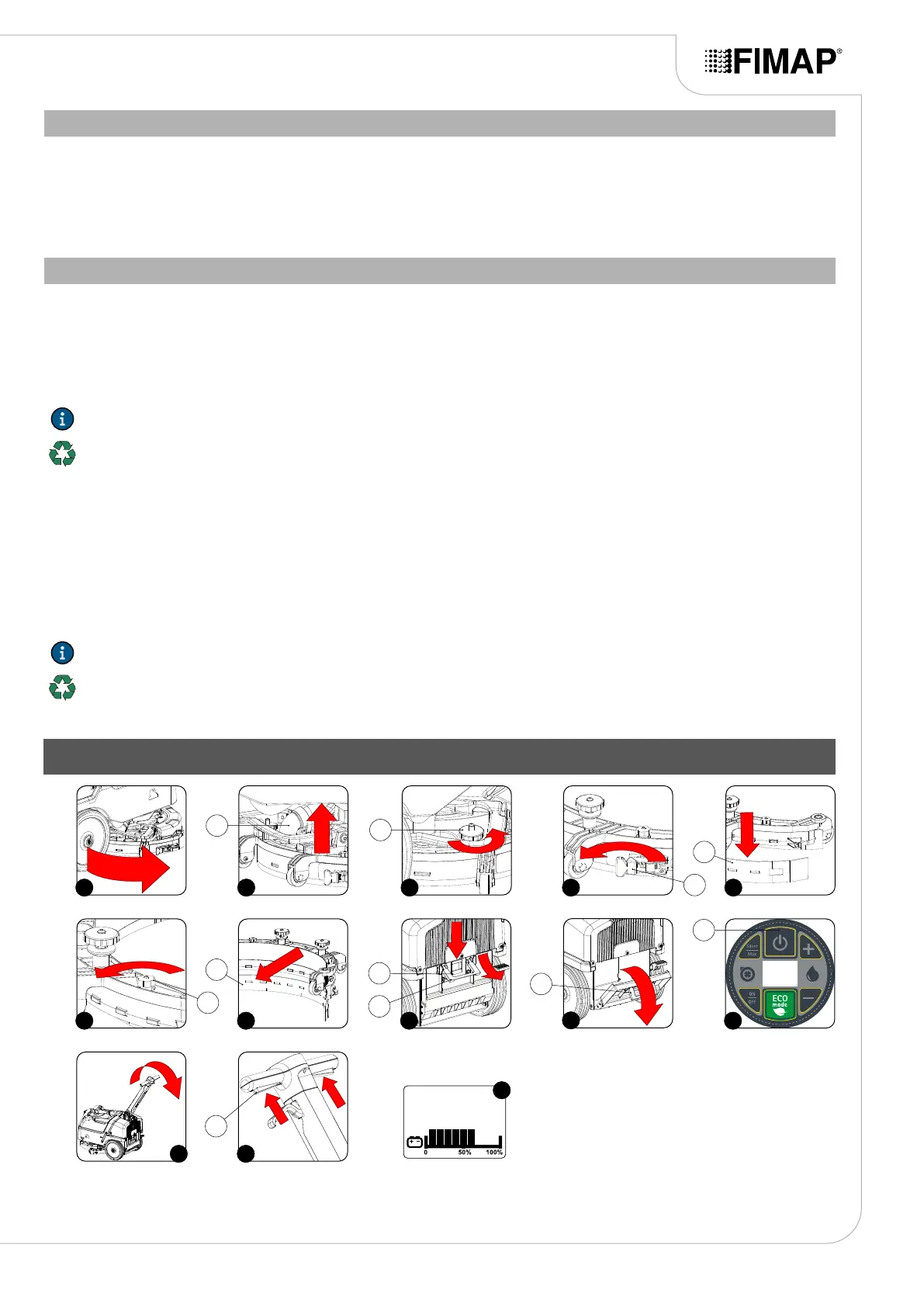

EXTRAORDINARY MAINTENANCE

23

3 4 5

2

3

4

1 2

6 7

1

5

6

1211

10

9

10

8

7

8

9

8

s

13

Loading...

Loading...