14

ARPEX 8704 en

Operating instructions 01/2019

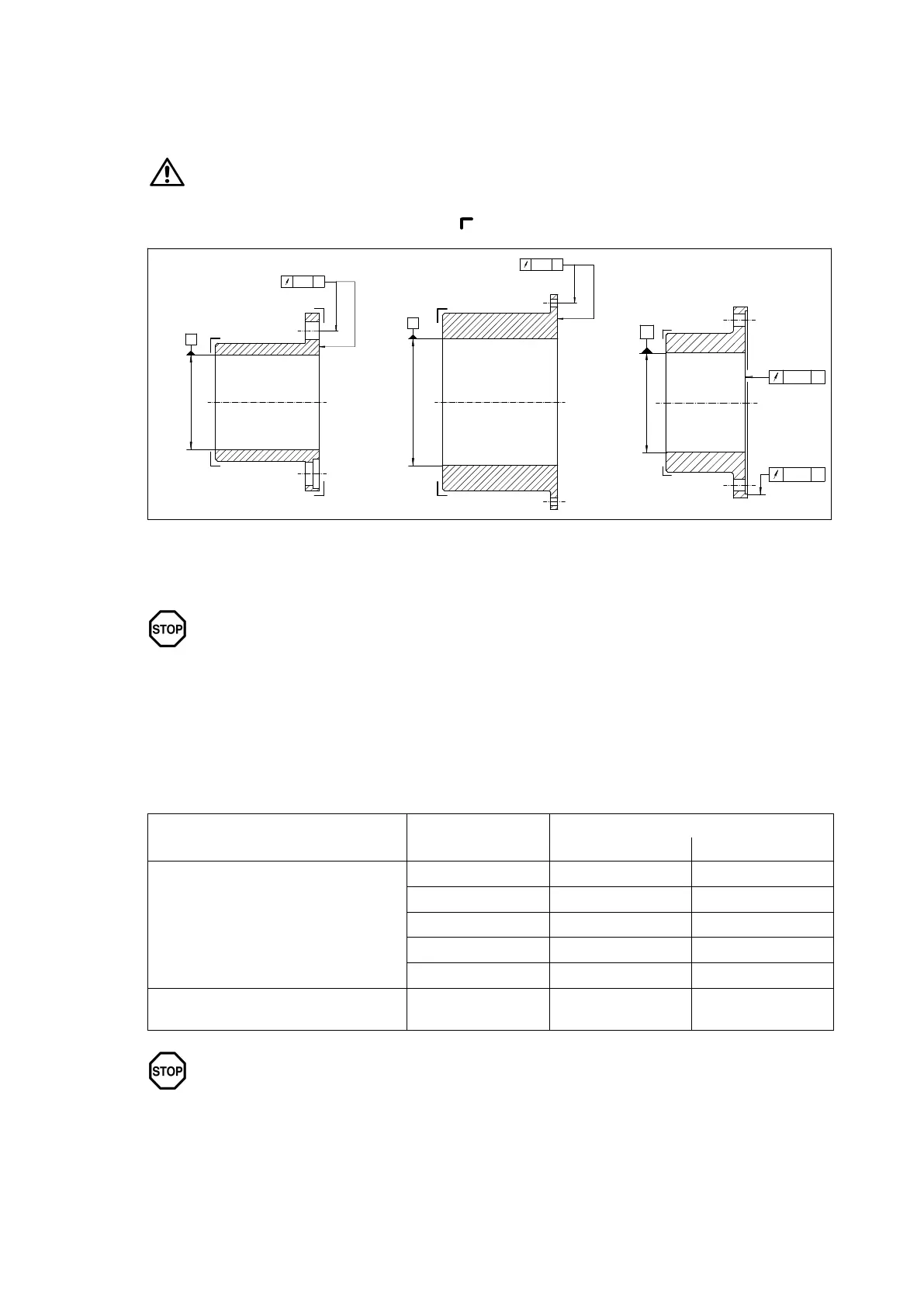

6.2 Instructions for machining the finished bore, axial fastening, set screws and balancing

6.2.1 Finished bore

Remove preservative agent from coupling parts.

Observe the manufacturer’s instructions for handling the solvent.

When machining the finished bore the parts must be carefully aligned.

The parts must be fitted on the marked faces (

) (see figure 4).

1

2

Ø D1

Ø D1

Ø D1

3

AIT 7

A

BIT 7

B

CIT 7

C

CIT 7

Fig. 4: Finished bore to ISO tolerances

1"N"-hub / "B"-hub

2"M"-hub

3"M"-hub

The maximum permissible bore diameters (see section 1, "Technical Data") are

designed for drivetype fastenings without taper action to DIN 6885/1 and must not

under any circumstances be exceeded. The finishmachined bores must be 100 %

checked with suitable measuring equipment.

If other shafthub connections (such as splined hub profiles, taper or stepped bores and drivetype

fastenings with taper action or other connections) are to be used instead of the drivetype fastenings

provided for, Flender must be consulted.

For drive by means of parallel keys the following fit pairs are prescribed for the bores (see table 3):

Table 3: Fit pairs

Type of fit Shaft tolerance

Bore tolerances

Reversing operation Setting-up operation

Interference fit with parallel-key

connection

h6 P7 N7

k6 M7 H7

m6 K7 H7

n6 J7 H7

p6 H7 F7

Shrink fit without parallel-key connection

to customer

specification

on request on request

The assigned fits must be adhered to in order, on the one hand, to keep the play in the

shafthub connection as low as possible, depending on utilisation of the tolerance

zones, and, on the other, to keep the hub tension arising from the oversize within the

permissible load limit. Failure to adhere to the assigned fits may impair the shafthub

connection.

Loading...

Loading...