22

ARPEX 8704 en

Operating instructions 01/2019

6.7.1 Fitting

Before fitting, the halfshells must be removed from the hubs and the holes carefully cleaned and

degreased using a suitable degreasing agent.

Observe the manufacturer’s instructions for handling the solvent.

Do not interchange halfshells.

Check that the number markings (markingpunch number) at the side of the hub core

are identical (see Fig. 14).

Place the clamping hubs on the shaft ends. The tension screws in the halfshell must first be evenly

screwed up only handtight.

Ensure the halfshells are evenly seated. Check the gap size is even and, if necessary,

adjust.

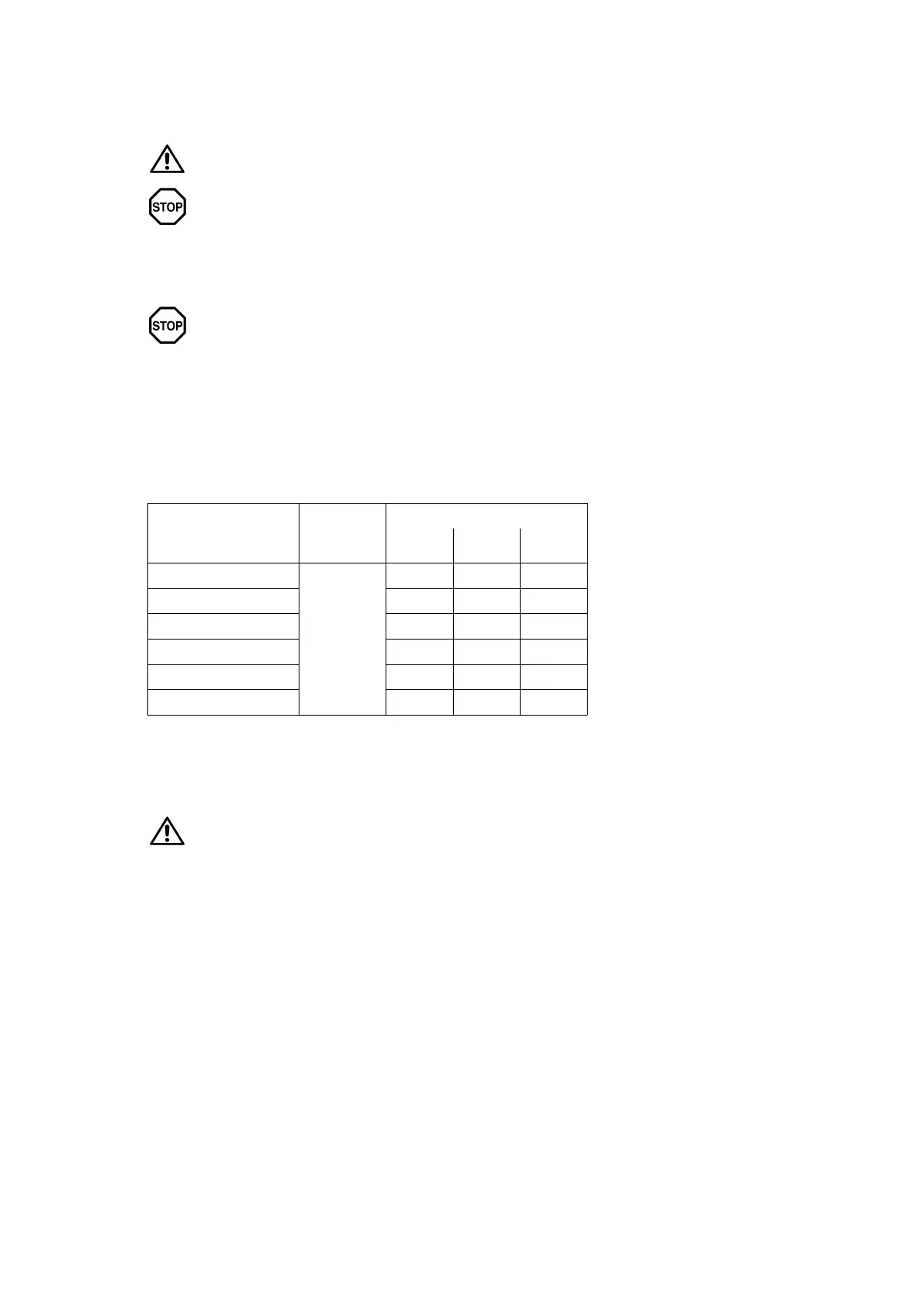

Then, using a torque wrench, tighten the tension screws alternately in at least 3 passes (see table 4).

First pass: Tighten the clamping bolts to 30 % of the tightening torque (see table 4).

Second pass: Tighten the clamping bolts to 60 % of the tightening torque (see table 4).

Third pass: Tighten the clamping bolts to 100 % of the tightening torque (see table 4).

Table 4: Tightening torques for split clamping hubs with halfshell

Bolt

Quality

Tightening torque

ISO 4762 (DIN 912) 30% 60% 100%

Thread [Nm] [Nm] [Nm]

M6

10.9

4 8 12

M8 9 18 30

M10 18 36 60

M12 30 60 100

M14 48 96 160

M16 75 150 250

6.7.2 Demounting

Demounting is done in reverse order of fitting. Here the tension screws must be undone alternately in at

least 2 to 3 passes.

Risk of injury from falling coupling parts.

Secure all coupling parts before undoing the clamping bolts.

Loading...

Loading...