27

Limitorque Actuation Systems L120 Series FCD LMENIM1201-04-A4 – 03/18

flowserve.com

• Quality – Inspect lubricant for dirt, water or other foreign matter. If any one of these is found:

1. Flush the actuator with a commercial degreaser/cleaner that is not corrosive and does not affect

the seal materials.

2. Repack the actuator with fresh lubricant allowing room for grease thermal expansion.

• Consistency – Ensure the lubricant is fluid approximating a standard NLGI-0 grade consistency or

less.

6.1.2 Factory Lubricant

Gear Case: The L120 series actuator gear case is factory-lubricated with an EP-0 lithium grease, suitable

for temperatures from -20°F (-29°C) to +250°F (+121°C).

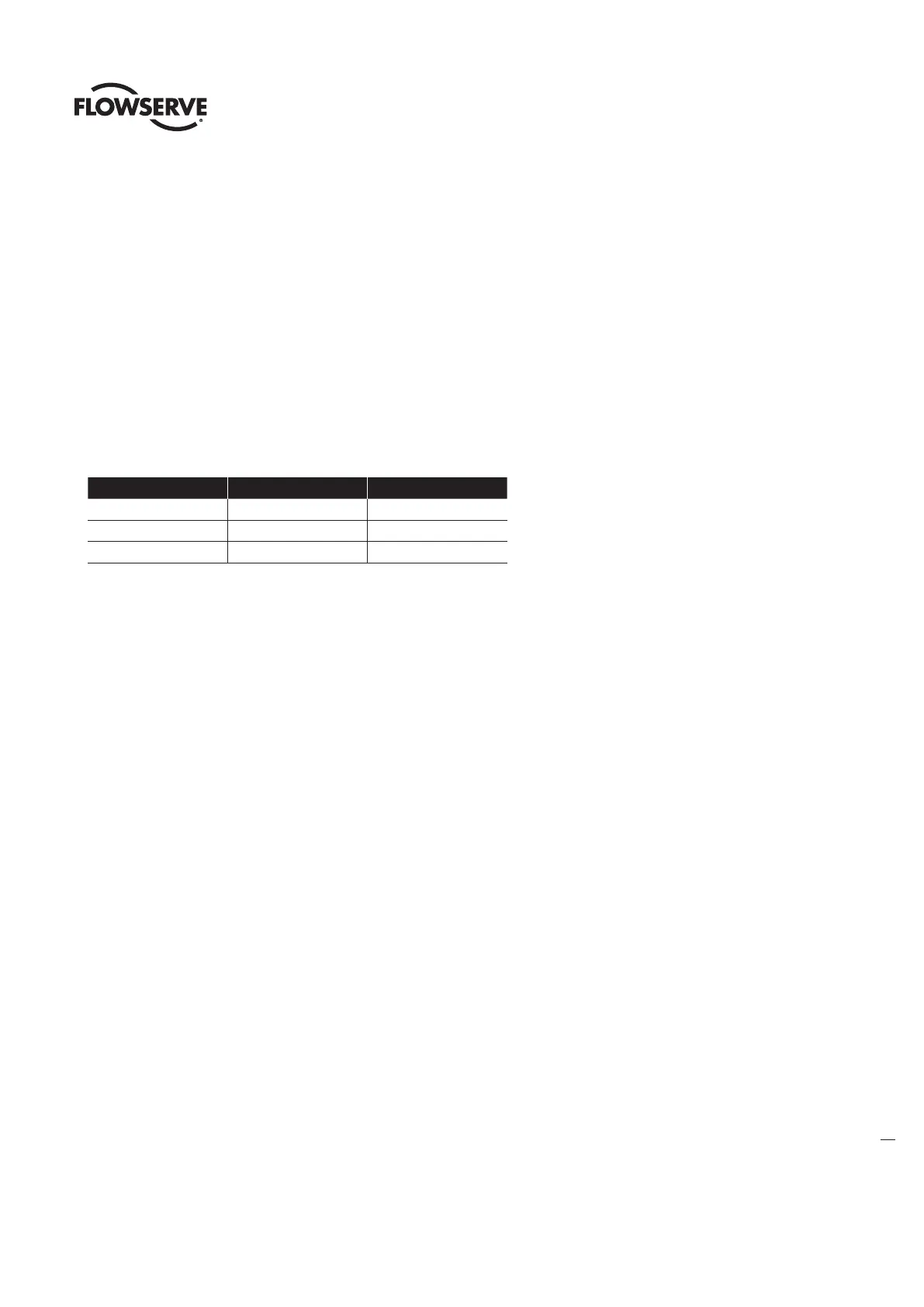

Table 6.1 – Specified Approximate Lubricant Weights

Actuator Size lb. kg

L120-10 2.75 1.3

L120-20 4.25 1.9

L120-40 5.75 2.6

Geared Limit Switch: Permanently lubricated with Beacon 325. Limitorque does not recommend disas-

sembly of the gearbox.

6.2 Minimum Lubricant Qualities Required

The standard lubricants used by Limitorque have been proven to be extremely reliable over years of

service. Limitorque does not recommend a particular lubricant substitute for the standard lubricants;

however, Limitorque does require the following lubricant qualities as a minimum.

a CAUTION: Do not mix lubricants of a different base chemical. Mixing lubricant bases may cause

lubricant properties to be ineffective.

The Lubricant must:

• contain an “EP” additive.

• be suitable for the temperature range intended.

• be water and heat-resistant and non-separating.

• not create more than 8% swell in Buna N or Viton.

• not contain any grit, abrasive, or fillers.

• comply with a slump-prefer NLGI-0 grade.

• not be corrosive to steel gears, ball, or roller bearings.

• have a dropping point above 316°F (158°C) for temperature ranges of -20°F (-29°C) to +250°F

(+121°C).

Loading...

Loading...