Logix 3000MD Series Digital Positioner FCD LGENTB0059-01 – 10/09

3

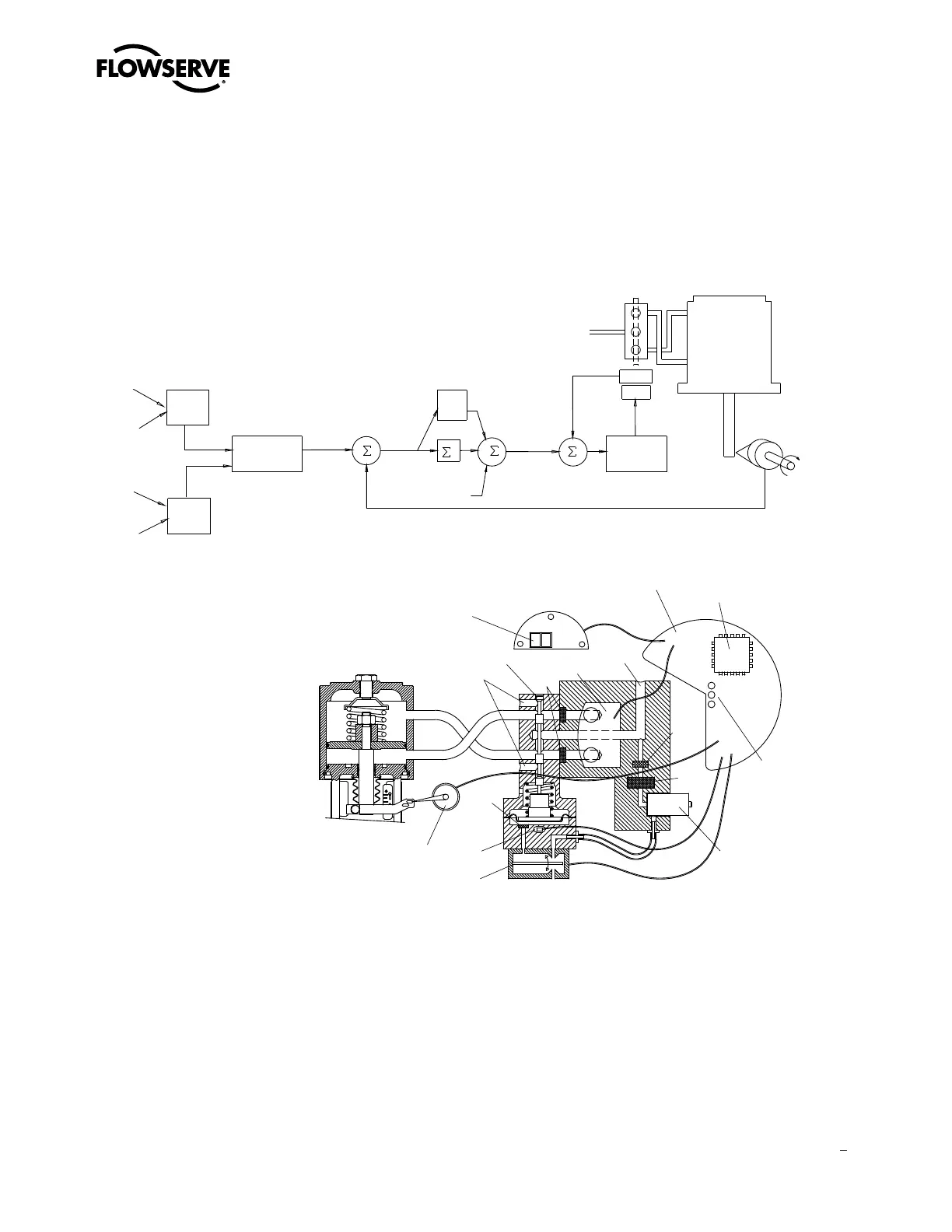

Sensor

-

+

+

+

+

Summer

Integration

I

Offset

Loop

Inner

+

-

Gmult

Pmin

Pmax

Deviation

F

OUNDATION

Fieldbus

Signal

Command In

(AO Block)

F

OUNDATION

Fieldbus

Transducer

Block

CONTROL

COMMAND

Output

D/A

Percentage

Algorithm

Control

Supply

Air

Control

Spool

Loop

Inner

ATO

Tubed

Sensor

Position

Stem

Voltage

Valve

Piezo

MPC

Soft Limits

Characterization

Linear Mode

Output

Inner-Loop

OR

Command In

(Digital Mode)

4-20

M

A

(A

NALOG

MODE

)

Input

Signal

A

NALOG

D

IGITAL

Logix 3200MD

Logix 3400MD

Figure 1: System Positioning Algorithm for Logix 3400MDDigital Positioners

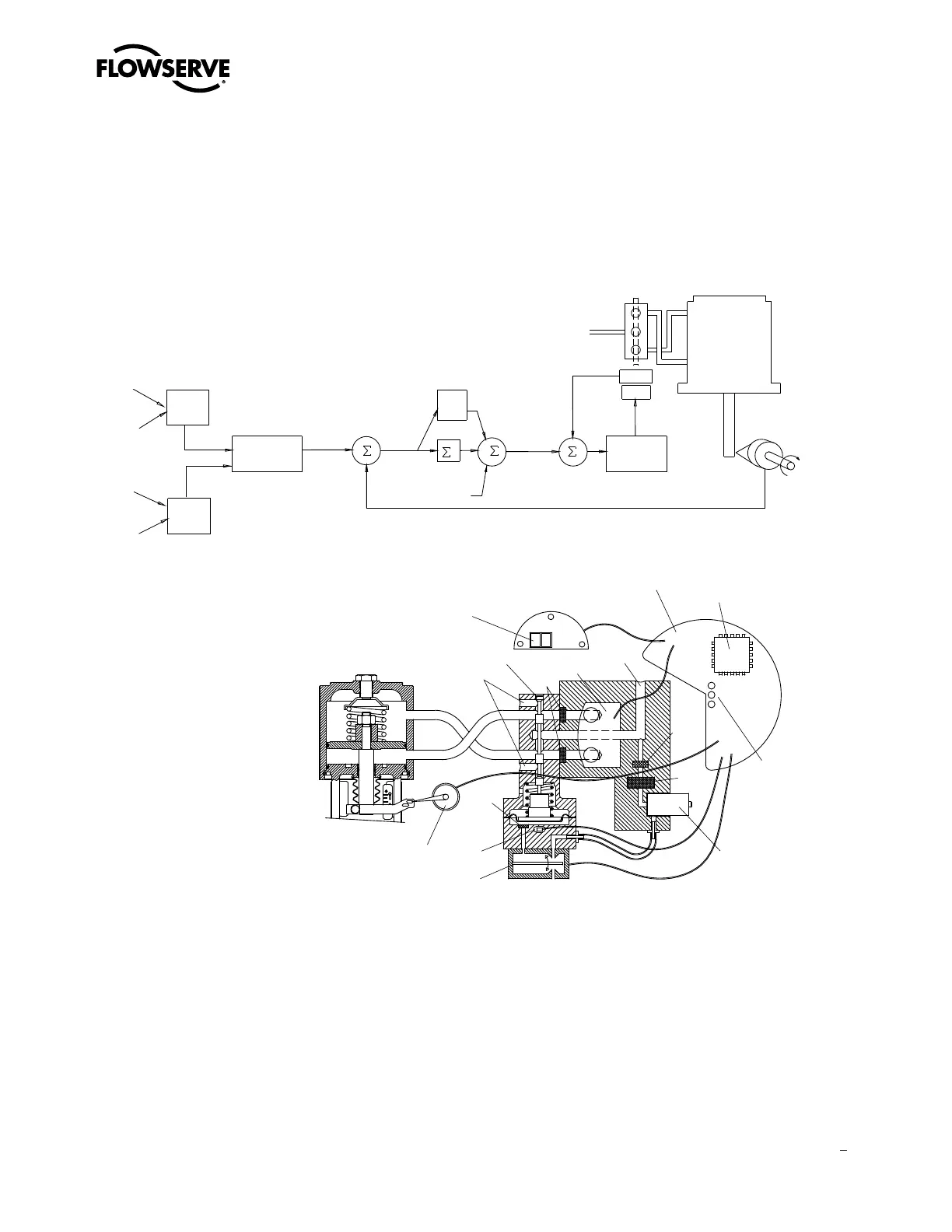

O O

Stem

Position

Sensor

Piezo Valve

Output 2

Output 1

Hall Effect

Sensor

Flame

Arrestor

Exhaust

Spool Valve

Flame

Arrestor

Pressure

Sensor Board

Air Supply

Main PCB

Regulator

Filter

Flame

Arrestor

Digital Position Algorithm

LED

Display

FF/HART

Input Signal

Figure 1: Logix 3000 Series

Digital Positioners Schematic

(air-to-open configuration)

Logix 3000MD Positioner Overview

The Logix 3000MD Series Digital Positioner - How It Works

Tu n i n g

Unlike other positioners that have only one set gains to set the response of the positioner, the Logix 3200MD positioner

uses a multi-variable variable gain tuning algorithm. This allows the positioner to make large step changes with minimal

overshoot, while achieving the resolution to respond to very small step changes.

The Auto Tune procedure cycles the actuator to produce a measured response and selects those gain values that provide

appropriate actuator performance. The Auto Tune function includes a gain modifier selector that can be used to increase or

decrease the calculated gain in order to achieve optimal performance.

By setting the Auto Tune on/off DIP switch, the tuning mode can be changed from auto to manual. The Logix 3000MD Series

positioners provide several preset gain settings with a locally adjustable gain set selector directly from the user interface on

the positioner. If custom settings are desired, tuning sets can be modified with a handheld or ValveSight, to accomodate a

wide range of actuator sizes and types.

Loading...

Loading...