User Instructions - Logix® 520MD+ Series Digital Positioner

FCD LGENIM0105-00

© Flowserve Corporation 30 Field Trial Version – Printed October 28, 2011

used to tightly close or open the valve. It is used when a

tight seal is needed or when debris or friction may

otherwise interfere with complete closure. When the valve

is commanded past the Shutoff points, the pilot relay will

direct full supply pressure to the appropriate port, applying

all available force to close (or open) the valve. The Shutoff

points apply to the Final Command.

CAUTION: Changing the Shutoff limits may cause the

valve to fully open or fully close after the command passes

a set limit.

Though Shutoff and Soft Limit features should not be used

together, if both are set, the greater of the two settings will

take precedence at the closed end; and the lesser of the

two settings will take precedence at the open end.

10.3.9 Configuration (Set Time and Date)

The positioner has an internal clock. The clock allows time

and date information to be stored with alarms and other

events. The clock does not account for daylight savings.

Set Time and Date – Use the ▲Up and ▼Down buttons to

set the time and date. The format of the time and date is

displayed above the input fields.

10.3.10 Configuration (User Preferences)

The User Preferences menu allows the user to format how

information is displayed.

The following table shows the available options. By default

the positioner is set to show information in International

System (SI) units. To change all units to North American

(English), make the selection under All Units. Each

selection can also be changed individually.

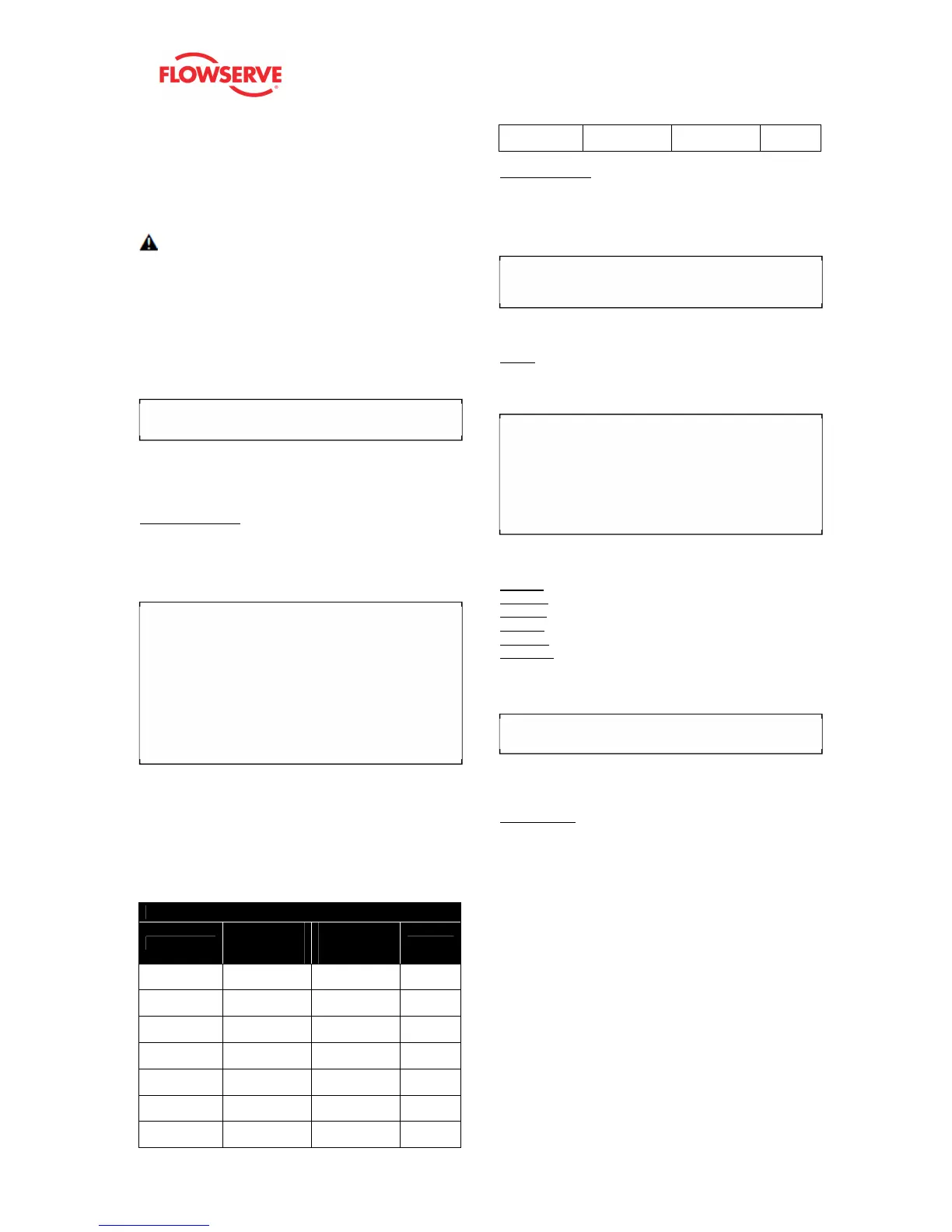

Table 17: User Preference Options

Units/Format

International

System (SI)

(Default)

North

American

(English)

Other

Options

All Units SI North American -

Pressure bar PSI

kg/cm2,

kPa

Force N lbf kg

Temperature degrees C degrees F -

Air Flow slph scfm

slpm,

Nm3/hr

Actuator Area

cm

2

in

2

-

Date Format Day.Mon.Year Mon/Day/Year -

Number Comma Decimal Point -

LCD Orientation – Use this selection to turn the turn the

display upside down (180 degrees). Use this feature when

the positioner is mounted upside down.

10.3.11 Configuration (Burst Mode)

Burst Mode continuously transmits HART information.

On/Off – Use this feature to turn burst mode on and off.

10.3.12 Configuration (Positioner Revs)

Positioner revisions are shown in this menu.

SW Rev –The revision of the embedded software.

Bld Date –The date of the embedded software build.

Bld Time –The time of day of the embedded software build.

HW Rev –The revision of the main board.

CPU Rev – The revision of the CPU.

HART Ver –The revision of the HART protocol (5, 6, or 7).

10.3.13 Configuration (Factory Reset)

At times, it may be convenient to reset all of the variables

to a default state. In this case, perform a Factory Reset.

Factory Reset – Use this feature to reset all variables to

their factory default state. All of the internal variables

including calibration will be reset to factory defaults. The

positioner must be re-calibrated after a factory reset. Tag

names and other user configured limits, alarm settings, and

valve information will also be lost and will need to be

restored. A factory reset will always reset the command

source to analog 4-20 mA.

NOTE: Once the Multi-Function Card (MFC) type has

been configured, the type selection will still remain after a

factory reset.

WARNING: Performing a factory reset may result in the

inability to operate the valve until reconfigured properly.

Notify proper personnel that the valve may stroke, and

make sure the valve is properly isolated.

10.3.14 Card 1 (or Card 2)

Two slots are available for auxiliary cards. The Multi-

Function Card (MFC) can be configured for analog output

(AO), Discrete Input (DI) and Discrete Output (DO). The

Safety Discrete Output card (Safety DO) provides highly

Loading...

Loading...