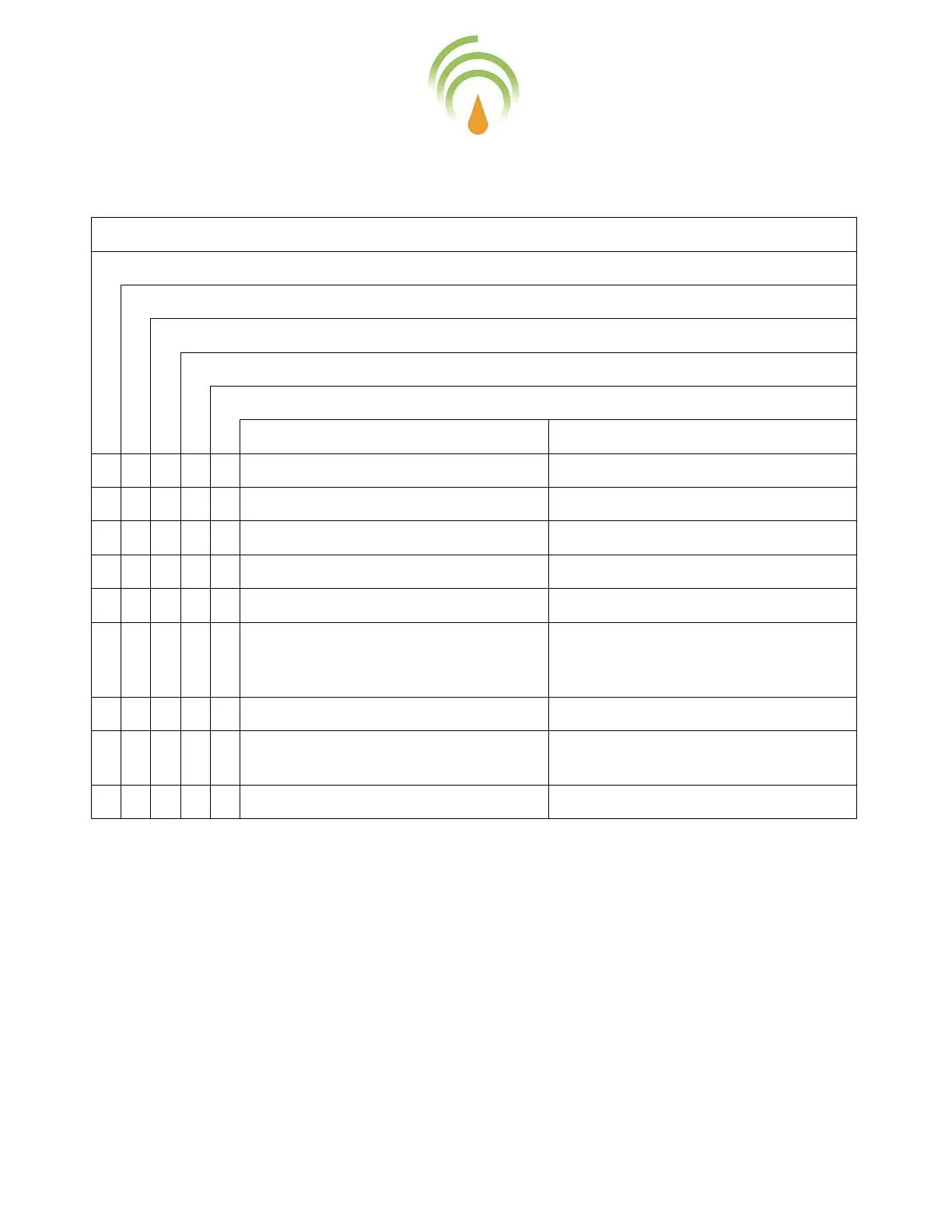

THE MACHINE DOES NOT START. THE ELECTRIC MOTOR DOES NOT WORK

THE MACHINE WORKS, BUT AFTER FEW SECONDS THE MOTOR STOPS

THE GEARMOTOR IS WORKING, BUT THE SCREWS DO NOT MOVE

THE SCREENED MATERIALS ARE NOT DISCHARGED WHEN EXITING THE MACHINE

Verify the electrical grid

Wrong electrical connections

Wrong motor protection settings

Grit tension is too low, Frequency is too high

Check the grid’s conditions

Check and replace the feeding screw

The gearmotor might have sustained some

damage

Check that the gearmotor is correctly

connected with the grid and that the 3 phases’

tension is the same that the one in the plate

The shaft bearings are damaged

High percentage of solid materials in the outlet

flow

Remove the materials blocking the exit

PROBLEMS IN TERM OF PERFORMANCE AND POSSIBLE SOLUTIONS:

1- Sludge at the outlet is not dry and/or a large

quantity of sludge comes out from the drum

2- Sludge screw press stops to discharge

the dried sludge

Flocculation is not good. Please check the flocculated

sludge at the inlet of the unit. Flakes must be big and

strong enough to be squeezed by the sludge screw press.

Please check the pressure of the pneumatic

counterweight. The pressure is probably very high. Please

check the activation instructions at page 23 of the present

manual.

Please check the inlet flow. May be that SD screw press is

receiving higher flow rate higher than the maximum

capacity.

Loading...

Loading...