070.650-IOM (AUG 2015)

Page 25

SGC ROTARY SCREW COMPRESSOR

MAINTENANCE

MAINTENANCE SCHEDULE

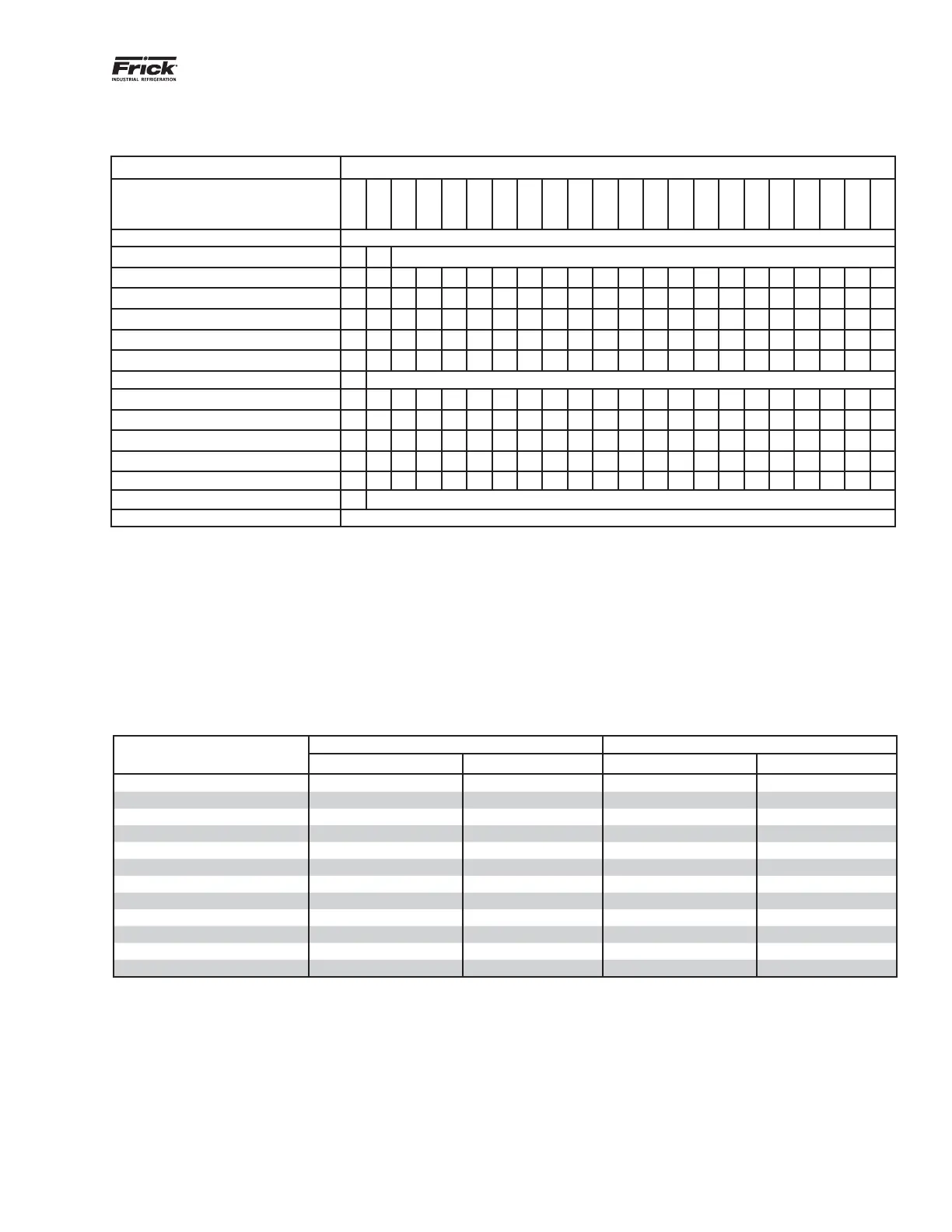

Recommended schedule for SGC/SGX Frick rotary screw compressor preventive maintenance operations.

a. Check bolts, shim packs, center inserts, keys, and all bolt torques.

b.Verifytightnessofboltsonsuctionanddischargeanges.See table below for torque requirements.

c. Units with variable speed drives - check for excess vibration and skip frequencies anytime unit operating conditions change.

d.Checkandtorqueallterminalsintheprocessorandstarterpanelperthespecicationpostedintheenclosure.

e.CheckcalibrationofSlideValve,SlideStop,pressuresandtemperatures.CalibrationshouldbeconductedwithNISTcertieddevices.

f. Vibration measurement must be carried out continuously to obtain optimum preventive control on bearings. If not continuously controlled,

then every 6 months, more frequently if levels increase.

FREQUENCY OR HOURS OF OPERATION (MAXIMUM)

MAINTENANCE

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change Oil As Directed By Oil Analysis

Oil Analysis

n

Every 6 Months

Replace Filters

n

n

n

n

n

n

n

n

n

n

n

Clean Oil Strainers

n

n

n

n

n

n

n

n

n

n

n

Clean Liquid Strainers

n

n

n

n

n

n

n

n

n

n

n

Replace Coalescers

n

n

n

Check and Clean Suction Strainer

n

n

n

n

n

n

n

n

n

n

n

Check Coupling

(a)

n

Annually Regardless of Operating Hours

Suction & Disch Flange Bolts

(b)

n n n n n n n n n n n n n n n n n n n n n n

VFD Units Check Skip Frequency

(c)

n n n n n n n n n n n n n n n n n n n n n n

Check Electrical Connections

(d)

n n n n n n n n n n n n n n n n n n n n

Check Sensor Calibration

(e)

n n n n n n n n n n n n n n n n n n n n n

Check BPR Function

n n n n n n n n n n n n n n n n n n n n n n

Vibration Analysis

(f)

n

Every 6 Months, More Frequently If Levels Increase

Replace Shaft Seal When Leak Rate Exceeds 7 - 8 Drops Per Minute

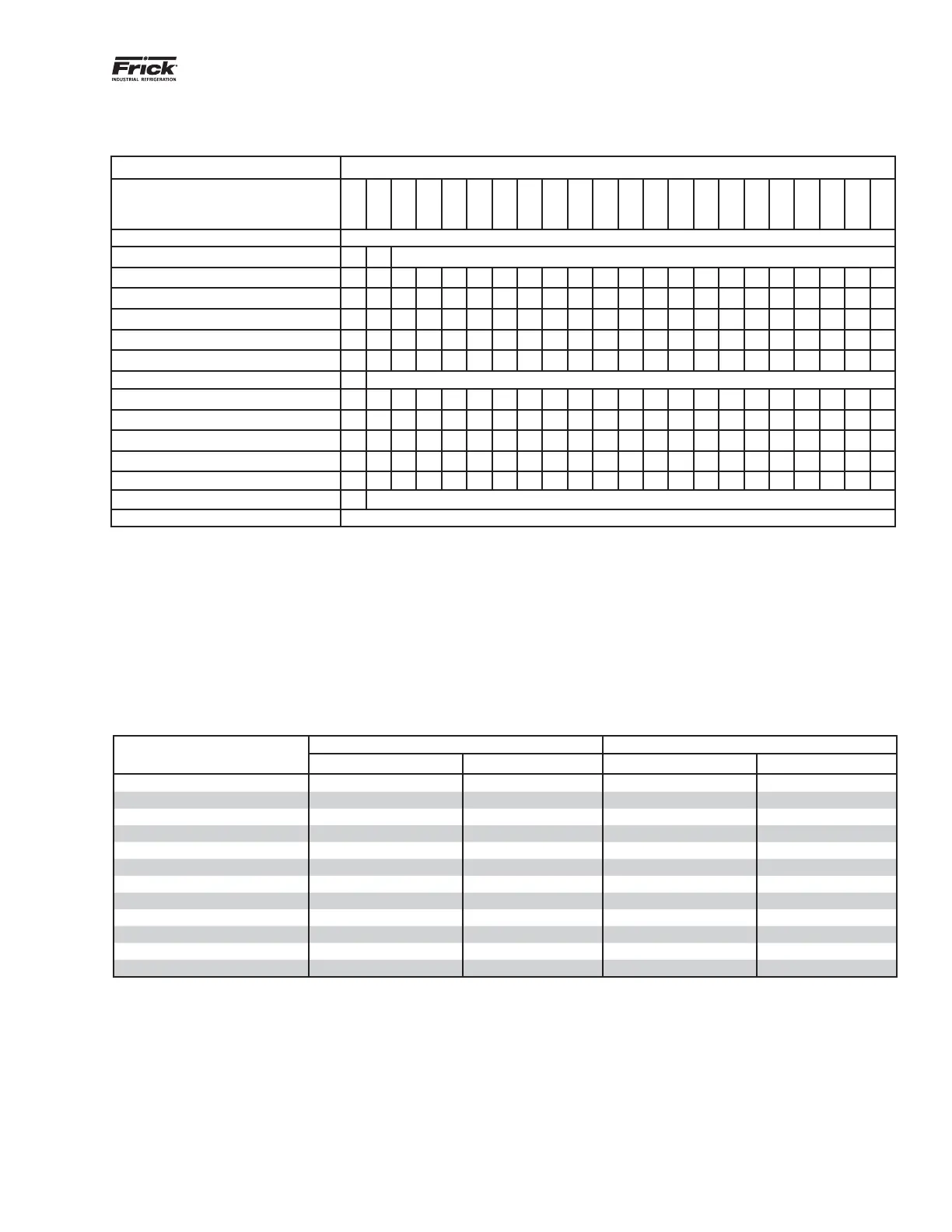

Compressor

Model

Discharge Flange Suction Flange

Bolt Size Torque* (ft-lb) Bolt Size (in.) Torque* (ft-lb)

SGC 1913 M20 X 2.5 140 M20 X 2.5 180

SGC 1918 M20 X 2.5 140 M20 X 2.5 160

SGC 2313 M20 X 2.5 160 M20 X 2.5 160

SGC 2317 M20 X 2.5 160 M20 X 2.5 200

SGC 2321 M20 X 2.5 160 M22 X 2.5 220

SGC 2813, 2817 M22 X 2.5 230 M22 X 2.5 220

SGC 2821 M22 X 2.5 230 M24 X 3.0 220

SGC 3511 M24 X 3.0 240 M30 X 3.5 350

SGC 2824 M22 X 2.5 240 M24 X 3.0 220

SGC 3515, 3519, 3524 M24 X 3.0 240 M30 X 3.5 350

SGX 4013 1.125-7 UNC x 4 650 1.125-7 UNC x 4 650

SGX 4018, 4021 1.125-7 UNC x 4 650 1.25-7 UNC x 4.5 825

* Based on: Gaskets-Garlock

®

Blue-Gard

®

3300; Bolts-class 8.8 or stronger hex head bolts, lightly oiled and clean

Table 5. Bolt Sizes & Torque

Loading...

Loading...