070.650-IOM (AUG 2015)

Page 4

SGC ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

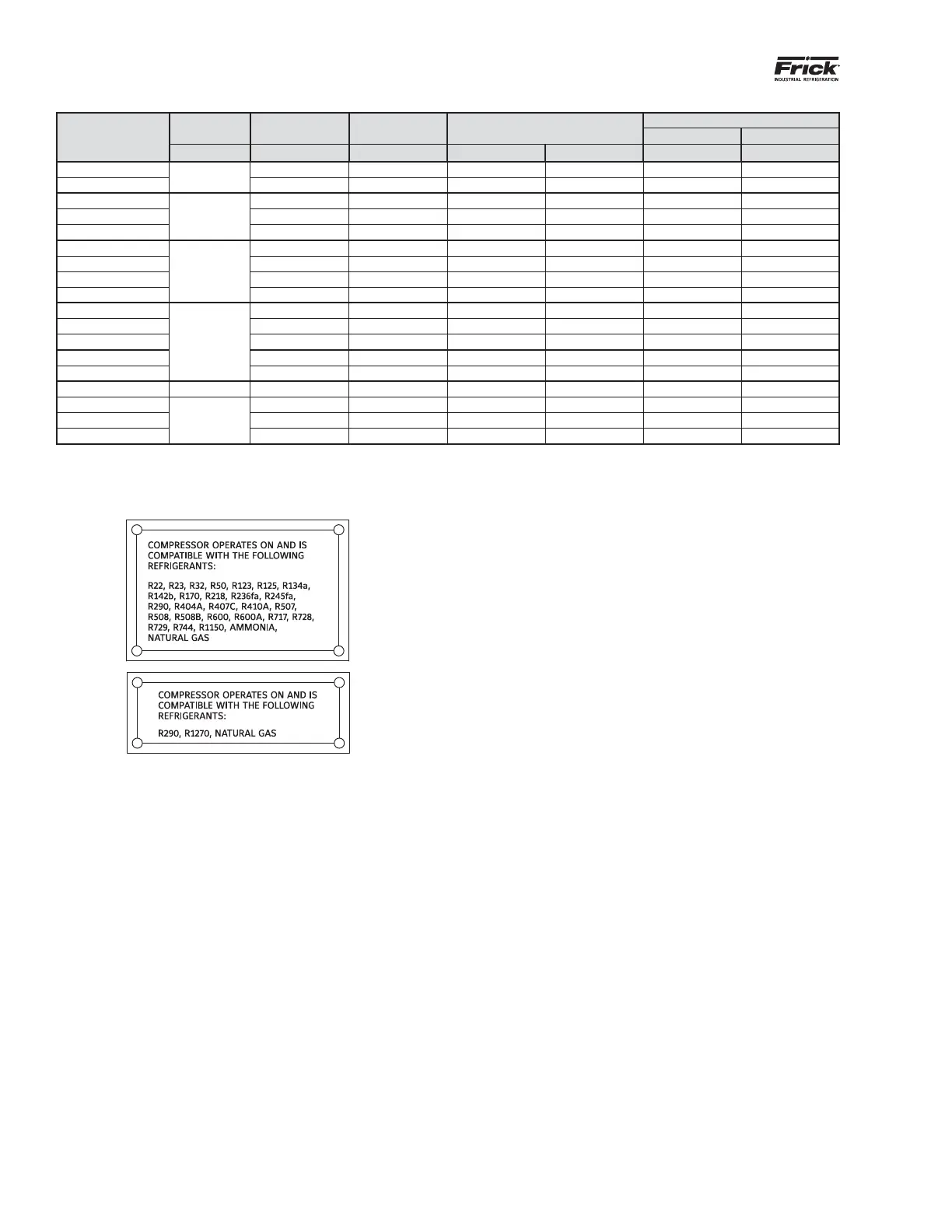

The name plates in Figure 2 show which refrigerants are

compatible with the compressor as manufactured.

Figure 2. Refrigerant Name Plates

LONG TERM STORAGE

Long term storage (6 months to 5 years) provisions are

required, regardless of storage environment, if start-up

and/or useful operation does not occur within six (6) months

of equipment shipment. Special provisions may be required

for storage of less than six (6) months if the storage area is

subject to unusual environment such as high humidity, large

changes in temperature, dusty atmosphere, etc.

The standard Johnson Controls-Frick Warranty for an SGC/

SGX screw compressor covers twelve (12) months from

start-up or 18 months from shipment, whichever comes

rst.Itisrecommendedthatarrangementsbemadewith

the local JOHNSON CONTROLS-FRICK service organization

(arranged through factory service) regarding surveillance

and maintenance during the storage period. It will be the

customer’s responsibility to submit a monthly report

showing the condition of the unit and noting any

discrepancies to the guidelines listed herein. Failure to

comply with this Long Term Storage Recommendation may

void the warranty.

Long term storage of equipment may lead to the

deterioration of components over the period of time.

Synthetic components in the compressor may deteriorate

overtimeeveniftheyarekeptoodedwithoil.Awarmand

dry environment is essential to minimize environmental and

corrosion damage. Long term storage of the affected

equipment at a customer’s site may involve additional

requirements and interested parties should refer to the

JohnsonControlswebsite,www.jci.com/frick,forspecic

instructions (Location: Bare Compressors\General\

Warranties\Screw Compressor Purchased for Long Term

Storage).

The following guidelines must be followed to maintain the

SCREW COMPRESSOR WARRANTY.

PREPARING COMPRESSOR FOR STORAGE

Evacuate compressor to remove moisture. Evacuation lines

are to be connected to port SM1. Evacuation lines are to be

connected to the three Schrader access valves provided

with the compressor. One valve is connected to compressor

suction. The other two valves are located at the block on

the cylinder.

Break vacuum with dry nitrogen and bring pressure to zero psig

.

Pump oil into the same ports mentioned in step 1. Johnson

Controls-Frick recommends break-in oil P/N 111Q0831809

for storage purposes. The amounts of oil needed per

compressor are:

95mm* 2 Gal. 233mm 15 Gal.

120mm* 3 Gal. 283mm 25 Gal.

163mm* 8 Gal. 355mm 35 Gal.

193mm 12 Gal. 408mm 50 Gal.

After compressor is oil charged, pressurize compressor to

15 psig with nitrogen.

MAINTAINING COMPRESSOR IN STORAGE

• Ensure that the 5-15 psig nitrogen charge is maintained

with 15 psig preferred.

• Rotate the male rotor shaft every two weeks. Mark the

shaft to ensure the rotor does not return to the original

position.

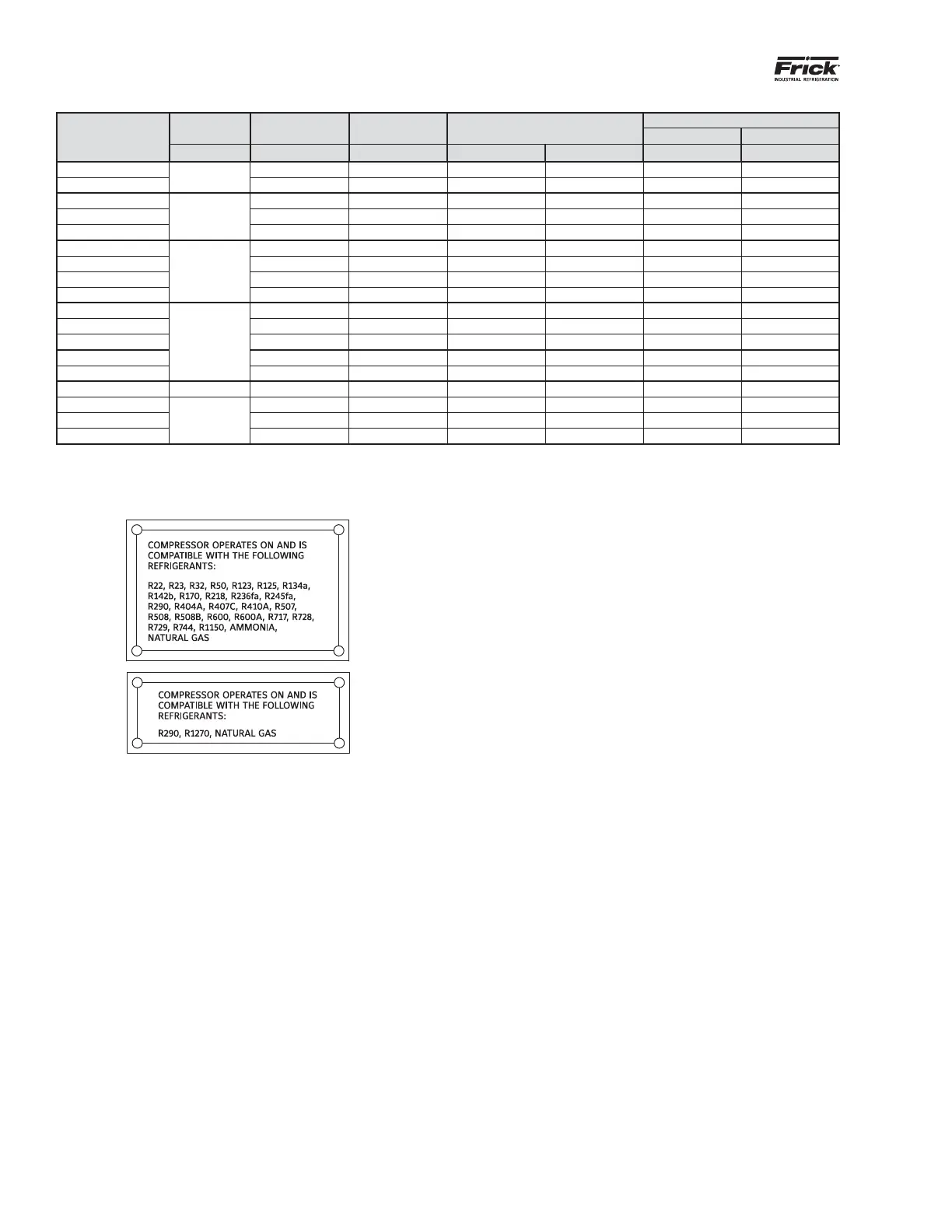

COMPRESSOR

MODEL

ROTOR

DIAMETER

ROTOR

MAX

SPEED

GEOMETRICAL SWEPT VOLUME

DRIVE SHAFT END

DISPLACEMENT

3550 RPM 2950 RPM

MM L/D RPM FT³/ REV M³/REV CFM M³/H

SGC 1913

193

1.35 4,500 0.16653 0.004713 591 834

SGC 1918 1.8 4,500 0.22204 0.006284 788 1,112

SGC 2313

233

1.35 4,500 0.29301 0.008292 1,040 1,468

SGC 2317 1.7 4,500 0.36897 0.010442 1,310 1,848

SGC 2321 2.1 4,500 0.45580 0.012899 1,618 2,283

SGC 2813

283

1.35 4,200 0.52501 0.014858 1,864 2,630

SGC 2817 1.7 4,200 0.66115 0.018711 2,347 3,312

SGC 2821 2.1 4,200 0.79546 0.022512 2,824 3,985

SGC 2824 2.4 4,200 0.89858 0.025430 3,190 4,501

SGCH/B 3511

355

1.1 3,600 0.82248 0.023276 2,920 4,120

SGCH/B 3515 1.5 3,600 1.12154 0.031739 3,981 5,618

SGCH/B 3519 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXB 3519 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXB 3524 2.4 3,600 1.80328 0.051033 6,402 9,033

SGXH 3519 355 1.9 3,600 1.42748 0.040398 5,068 7,150

SGXH 4013

408

1.3 3,600 1.41180 0.03998 5,012 7,076

SGXH 4018 1.8 3,600 1.95481 0.05535 6,940 9,798

SGXH 4021 2.1 3,600 2.31319 0.06550 8,212 11,594

Table 1. Geometrical Swept Volume

*For reference only. These are non-SGC/X compressors.

Loading...

Loading...